ADR equipment and systems that make your needs the priority

ADR Systems that simplify the metals recovery process

Our ADR Systems promise sustainability and productivity

To get the most out of your processing plant, it is essential to have a system that maximises gold and silver recovery as efficiently as possible.

We believe it’s our responsibility to produce equipment that is both sustainable and productive, and for this reason, we proudly offer our range of ADR equipment and systems. We have engineered our ADR technology to be light on power usage without sacrificing time or recovery.

Through FLSmidth systems, we offer the complete silver and gold recovery flowsheet including materials handling, crushing, milling, leaching, adsorption, recovery, and refining to produce gold and silver doré.

Our equipment and systems are robust and require little maintenance. As most mine sites are not located near urban areas, we design and build for longevity and trouble-free service. Our design and development teams benefit from years of in-house and field testing, and our products have been created and are continually updated to provide longstanding performance in the most demanding conditions presented in the mining industry.

We stand behind our quality products. All components, equipment and systems are covered under the FLSmidth one point of source sales warranty, eliminating the need to get warranty help from individual component suppliers.

Our equipment and systems are available with many options, making our products versatile and easier to tailor to your specific needs. Depending on your project location we can utilise our global supply chain to optimise equipment sourcing and fabrication locations to best suit your project needs and ensure we can support your operation over the entire mine life.

FLSmidth Systems

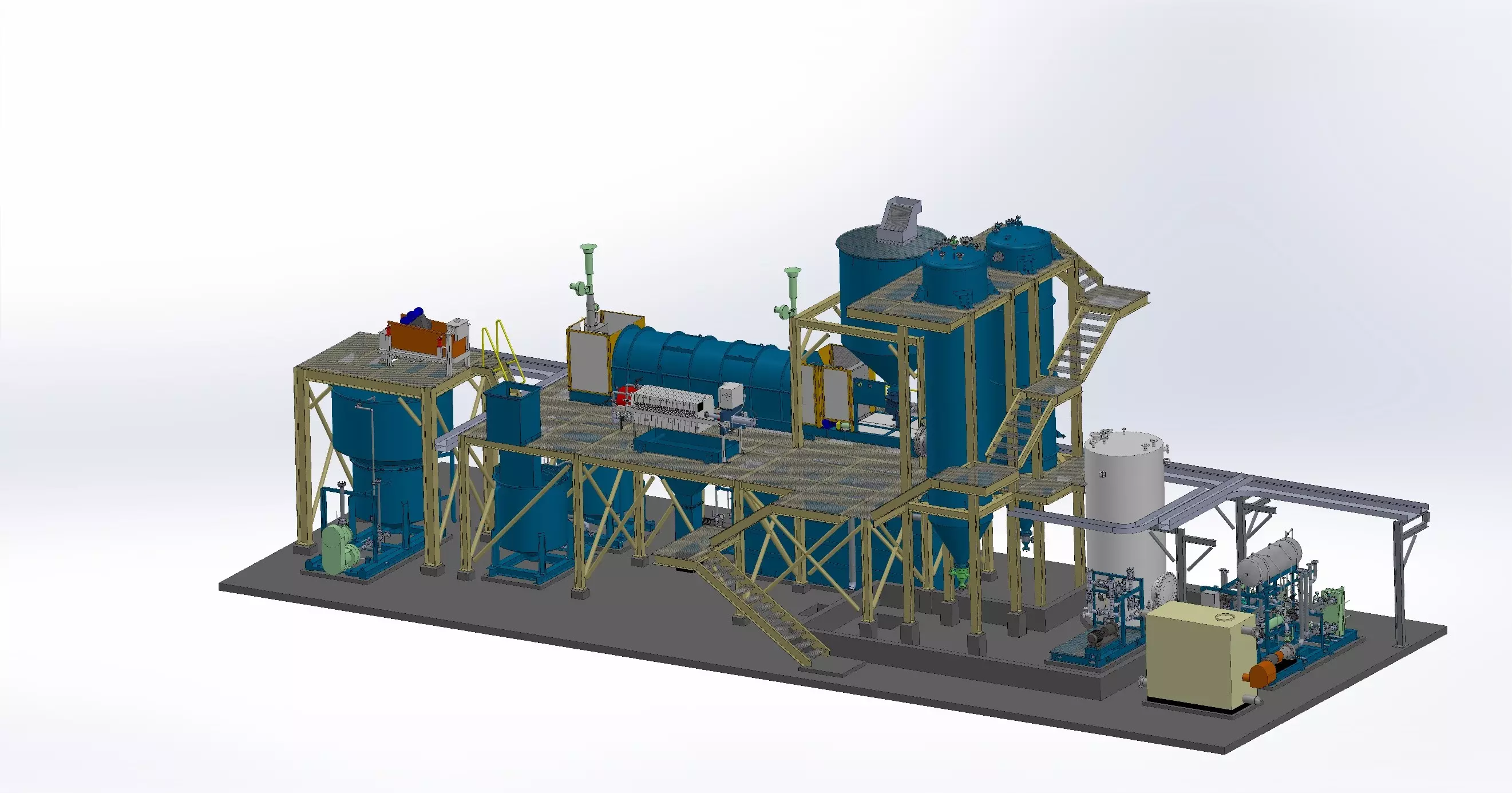

- Modular/Packaged ADR Plants – complete carbon processing plants from adsorption to electrowinning, carbon regeneration and handling, and precious metal sludge refining.

- Leaching/Adsorption – Carbon in Leach (CIL), Carbon in Pulp (CIP) and Carbon in Column (CIC)

- Acid Wash – HCl and HNO3 Systems

- Elution/Strip – pressurised ZADRA, AARL Desorption Systems, and the innovative Patented Summit Valley Split-Strip (ZADRA)

- Electrowinning – direct electrowinning, gravity concentrate (intensive cyanidation) electrowinning, and elution electrowinning systems

- Refinery – Smelting Furnaces, Mercury Retorts, Sludge Dryers and Calciners, and Baghouses

- Mercury Abatement Systems – Electrowinning Cell Exhaust, Carbon Regeneration Kiln Process Gas, Smelting Furnace Flue Gas and Refinery/Plant Room Ventilation

- Cyanide, reagent, and utility packages

FLSmidth Proprietary Equipment

- Acid Wash Tanks – Fiberglass Reinforced Plastic, 304SS and Carbon Steel Rubber Lined

- Elution Vessels – ASME VIII/Similar spec Pressure Vessels in Carbon and 304/316 Stainless Steel

- Elution Heater Skids – complete skid mounted Heaters, Heat Exchangers, Strainers, Instrumentation and Control Panels

- Electrowinning Cells – innovative 304SS design allows for in-cell washing of basketless cathodes using a high-pressure sprayer; customisable design decreases operator service times

- Carbon Regeneration Kilns

- Mercury Retorts