Mercury Abatement Systems designed to meet your mercury emission limit

Mercury Abatement Systems that promise safety and longevity

Compact and versatile Mercury Abatement Systems

As a global leader, it is our responsibility to come up with solutions to problems such as health risks and environmental impact.

At FLSmidth, we recognise that mercury in metals recovery processes is highly dangerous and has been linked to neurological diseases and conditions, as well as other health concerns. Global pollution of mercury into the atmosphere is also increasing, causing damage to the environment and potentially harming all lifeforms.

With sustainability in mind, we have manufactured Mercury Abatement Systems, a range of equipment that is designed to remove mercury from the metals recovery process. Made of stainless and carbon steel, our systems are robust, compact, and versatile, as they are able to treat a wide variety of materials. They are adaptable, as they have been designed to work with a range of different metals recovery circuits and equipment, such as the Merrill Crowe circuit, the Carbon Regeneration Kiln, the Gold Electrowinning Cell, the Melt Furnace and Refinery Air treatment.

We have worked closely with environmental authorities and site managers in the development of our systems. Whatever your requirements are, we are confident we have a mercury solution for you.

Mercury Retort

We offer the Summit Valley™ Mercury Retort, a machine designed to remove mercury from gold sludge using vaporisation. It is capable of safely meeting temperatures between 200° C and 600° C, but this can be adjusted to suit conditions on site. It comes in two distinct designs; the smaller barrel-style oven, and the larger cabinet style ovens, well suited for the large production capacity Merrill Crowe circuits.

Process Equipment Mercury Abatement

Our Process Equipment for Mercury Abatement stands on 20 years of experience and has been designed to keep you and your workers safe. With its purpose to keep mercury emissions to a minimum, it offers accessibility and ease of maintenance. Our Mercury Abatement Systems have been manufactured to capture mercury vapor in the process exhaust streams of gold and silver recovery circuits. They are small systems designed to meet and surpass toxic mercury emission limits for your mine-site. Our systems are complete and are correctly sized to fit in with much larger equipment.

If your orebody contains mercury, you can have the assurance of protecting your workers and the environment by installing our mercury capture equipment. The carbon strip and electrowinning circuit, carbon regeneration kiln and refinery smelting furnaces will all need mercury control.

Our systems have been adapted to how these specific streams function and are versatile and more suited to a particular need.

Key benefits

- Safer operation

- Easy maintenance

- Minimal space requirements

Mercury abatement equipment that offers a smaller footprint

When performing precious metals recovery, it’s essential to recognise the potential dangers of mercury to your workforce and environment and to actively search for ways to prevent risk. This is why at FLSmidth, we recommend our Mercury Abatement Process Equipment, designed to lower emissions and minimise the danger of mercury poisoning.We have manufactured process equipment to treat exhaust streams safely, in order to capture and dispel mercury efficiently. You can find this equipment specifically designed for precious metals recovery and refining systems, which include Zinc Precipitation (Merrill Crowe), Carbon Adsorption & Elution Circuits, and precious metals refining. For Merrill Crowe, we offer our large capacity Mercury Retorts and Retort Room equipment. For Carbon ADR Plants, we offer systems for the Gold Electrowinning Cell, the Carbon Regeneration Kiln and the Smelting Furnace, and provide our smaller capacity Mercury Retorts.

While the abatement equipment completes similar results within these systems, due to their individual nature, each system has been made slightly different to accommodate the individual process.

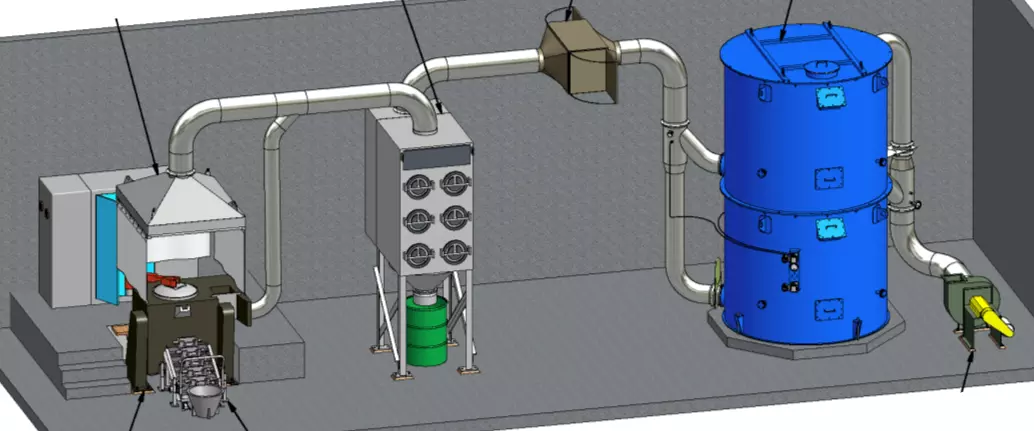

Gold Electrowinning Cell

The mercury contained in the electrowinning cell off-gas must be recovered amongst water vapour. The exhaust gas is passed through the Electrowinning Demister vessel to remove any condensed water and mercury, and then the stream is heated. Once heated, the process stream is sent to the Adsorption Vessel, where mercury is scrubbed using sulphur impregnated carbon (SIC).

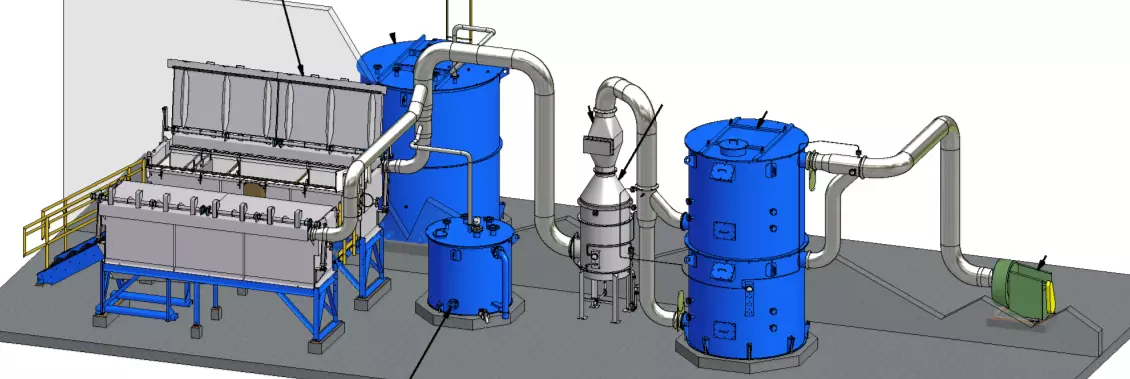

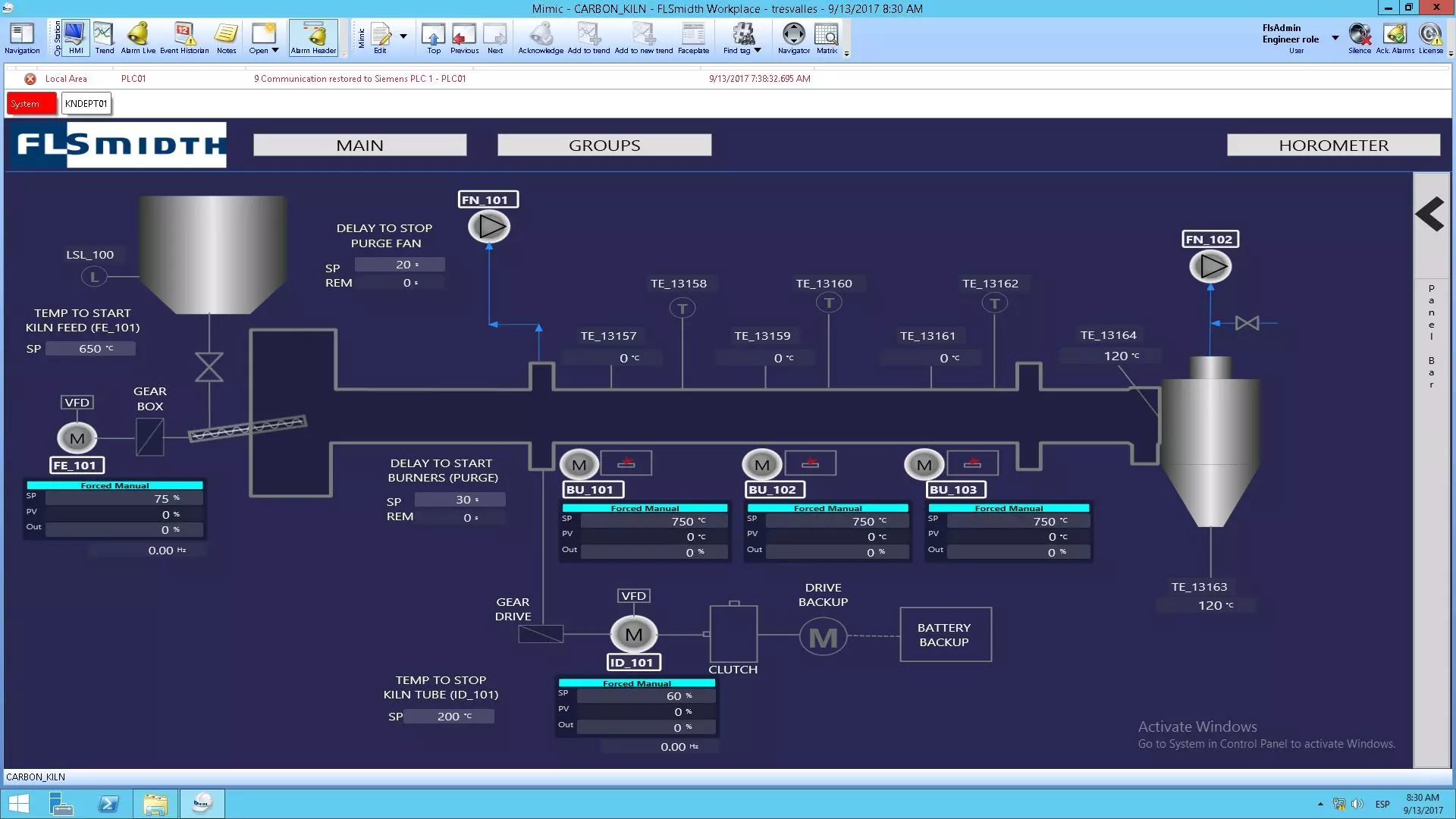

Carbon Regeneration Kiln

The mercury may exist as vapour, contained in condensed water, or could be entrapped on or in carbon fines. The mercury must be recovered from this particle-laden and moisture-rich stream. For the effective removal of fine particles, the exhaust gas is initially passed through the Carbon Fines Knockout Box to remove fine particulates. The stream is then passed through a cooling heat exchanger where mercury and water vapour is condensed and collected. After the stream has been cooled, it is then reheated and moved to the SIC Adsorption Vessel, where it is adsorbed.

Melt Furnace

Advantages that provide security and simplicity

-

Safer operation

- During processes where heat is applied, the equipment possesses systems designed to regulate the temperature, reducing fire hazard risks. The equipment also comes with interlocking safety systems, intended to prevent your workers from facing mercury exposure.

-

Easy maintenance

- We have engineered our equipment to be accessible with easily identifiable ports, connections and instrumentation, making the process of maintenance a lot simpler.

-

Small space requirements

- The equipment used in our mercury abatement system is correctly sized and compact where possible. Our systems fit nicely alongside the source equipment or may be located near the source stream.

Features designed to optimise the mercury abatement process

We provide you with all of the features you need to have an optimal mercury abatement system. With our equipment, we always keep safety and simplicity in mind.Particle collection equipment

The systems for streams containing particulates either come with a HEPA Filter or a Knockout Box, which are responsible for capturing any particles.

Condensing equipment

The Kiln and Retort Exhaust come with condensing heat exchangers, designed to condense mercury vapours prior to final stream scrubbing by the sulfur impregnated carbon-containing adsorption vessel.

Demisting components

Demisters are used in the high-moisture-containing systems to remove condensed moisture.

Heating equipment

Heaters are used with the high-moisture-containing Kiln and Electrowinning systems to prevent water condensation and subsequent fouling of the SIC carbon.

Carbon-bed components

SIC carbon absorbers are used in each of our systems to scrub mercury vapours from the exhaust stream.