-

Canada - FLS service centres

Mining services – here when you need us

No one can afford extended periods of downtime. So, when it comes to mining services, you need expertise on your doorstep. Our facilities are fully equipped to support you with repairs, spare parts, refurbs, and troubleshooting, quickly and efficiently. No long lead times. No long delays.

Your local expert mining service centres

Our service centres are spread across Canada to serve the mineral industries by providing world-class services where they’re needed. With state-of-the-art manufacturing and welding facilities, and world class engineering expertise onsite, we offer a one-stop-shop for equipment services and support.

Find contact details, address and directions:

A full suite of mining services

From east to west – service centres near you

Timmins, Ontario

Wabush, Newfoundland and Labrador

Equipment we repair

Our facilities are fully equipped to inspect, repair and refurbish your heavy equipment, including:

- Crushers

- Screens

- Sizers/Grinders

- HPGRs

- Apron Feeders

- Gearboxes

- Conveyors

- Pumps, cyclones and valves

Capabilities

- Management and/or delivery of spare parts

- Production of basic components

- Refurbishment and repair of wear parts

- Training and assessments

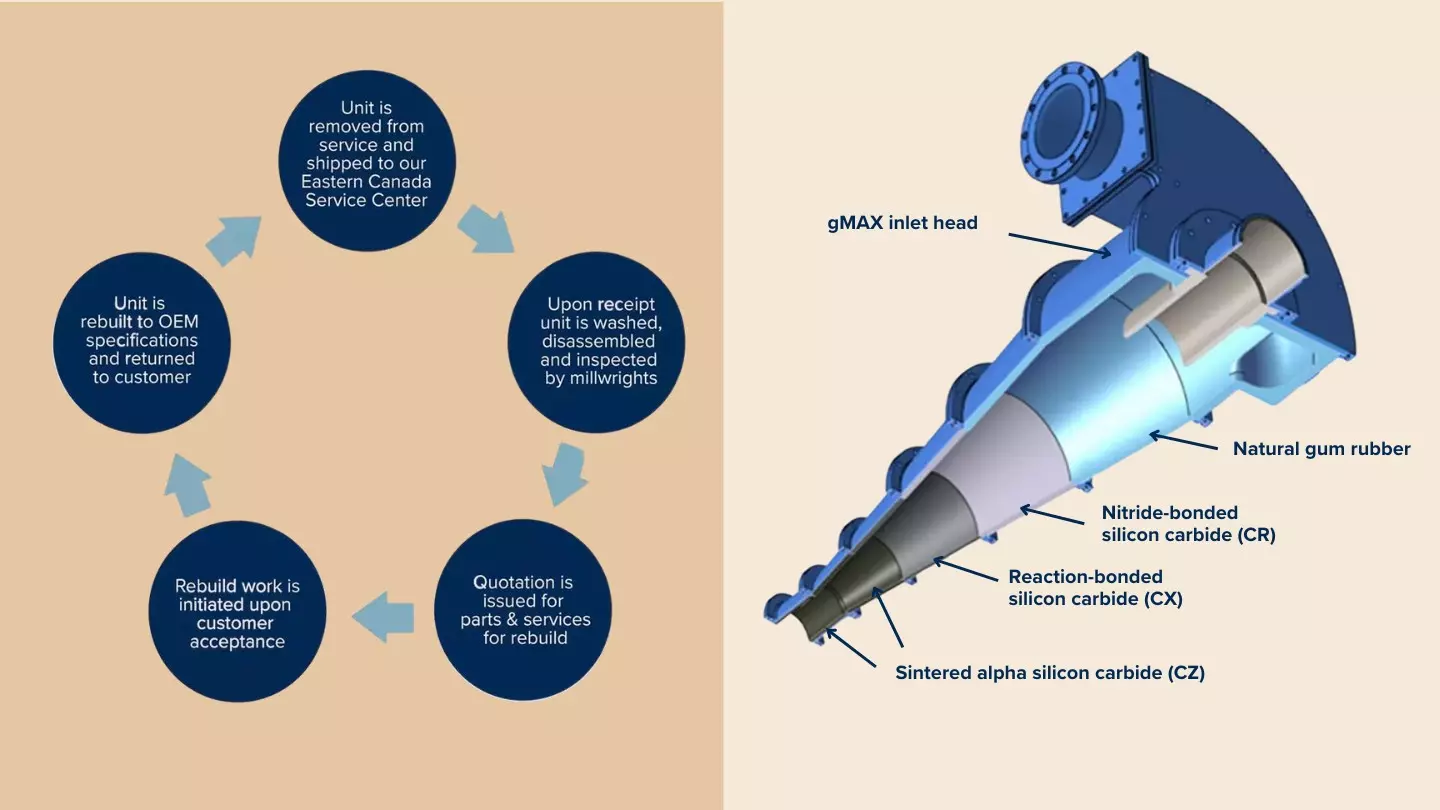

PCV rebuilds

Our pump, cyclone and valve rebuild programs enable you to reduce your onsite maintenance, stop worrying about on-site stocking, and maximize cyclone wear life to increase availability and uptime. Not only do we restore your cyclone, but our trained technicians carefully inspect the wear patterns to make sure that you have the optimal liners for your operations. For example, to combat higher wear zones in cyclone's lower cones and apex, more wear resistant ceramics can be used.

Bringing OEM standard services to you

From gearbox repair to plate welding, and everything in between, our service centres have the tools necessary to perform even complex jobs to the highest standards.

As an OEM, we know the importance of build quality – and how much money can be saved by bringing equipment back to as-new condition. Our dedicated facilities and expert engineers enable top quality repairs, refurbishment and retrofits that optimise equipment performance without breaking the bank.

Bespoke training programmes available