- Home

- Services

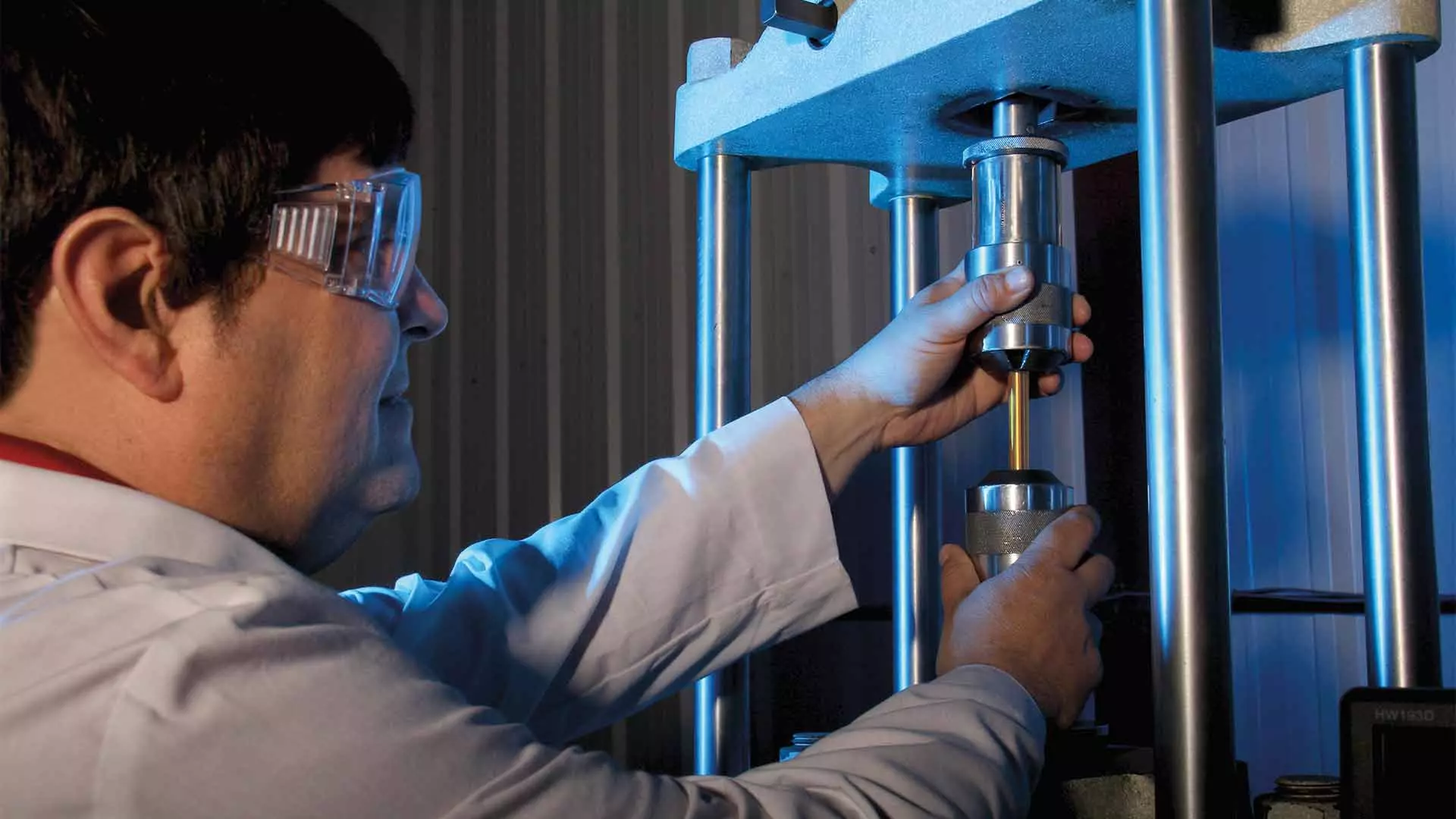

- Testing and research

-

Metallurgical and manufacturing expertise

We offer metallurgical and manufacturing expertise for mining

Our metallurgical and manufacturing expertise improves products

Our expertise pushes to improve your business through machinery backed by innovative research to unmatched customer service and support. Drawing from specialists and engineers, we put this knowledge to good use, providing some of the best solutions in the business.

Expertise and effectiveness

The mining industry might be high pressure, but your operation won’t have to worry about whether it’s making the right decisions. We are committed to providing invaluable service and backs that promise with qualified, experienced specialists and engineers. Our metallurgical and manufacturing expertise helps your business run smoothly. Enjoy less down time, quality alloys, custom designed solutions and consistent results with EXCEL™ products and expertise.

Metallurgical and manufacturing expertise to empower your business

You want the best for your business, and so do we. By honing our metallurgical and manufacturing expertise, we have worked to ensure your business can run at optimal levels and you can receive the best possible return on your investment. We want to provide safer, more efficient machines, and that’s only possible by knowing the industry inside and out.

-

Faster turn-around times

-

When you need solutions fast, we have you covered. Our turn-around times lead the industry, so that your operation will never have to wait longer than absolutely necessary for vital solutions.

-

Top-notch alloys

- We work with only the finest materials. This allows us to provide durable solutions capable of withstanding the extreme conditions commonly found in the mining industry.

-

Custom design specifications

-

Mining isn’t a one-size-fits-all industry. In fact, sometimes none of the available options are the perfect fit for your applications. This is why we offer customised engineering solutions. With EXCEL™, you’ll always have the right parts for the right job — even if we have to design them ourselves.

Our metallurgical and manufacturing expertise ensures innovation

Our innovative and cost-effective designs exist due to its metallurgical and manufacturing expertise. We know the science and industry, so you can get the best products for the best cost. We’re always pushing to improve, turning new ideas into successful results. With our insights we aim to provide quality products and customer service to help you improve your business.

Read more about how EXCEL's metallurgical and manufacturing expertise can provide the best possible experience for customers:

Clear advantages

You expect a lot from your equipment, which is why you can expect a lot from us. Our metallurgical and manufacturing expertise provide clear advantages for your business.

- Custom design specifications for your application

- ISO9001 quality system ensures consistent results

- Traceability program maintains peak quality

- Top-notch alloys including brass, bronze and manganese steel

- Tight dimensional tolerances

- Fast turnaround times

To give you the above advantages, we use the following principles to guide how we work:

Accountability: Trust is key. That’s why we stand behind our work 100% with outstanding customer service and excellent turnaround times.

Performance: We provide single-source responsibility — no further machining or quality control is required.

Expertise: We deliver on critical components and difficult projects that require high tolerance levels.

Capability: We utilise some of the most advanced machining tools in the world. With 160,000 square feet of manufacturing space, we provide industry leading turnaround time, shaving weeks off the production timeline.

Manufacturing

The way we run our manufacturing saves you money and time, while providing quality products. When you choose to work with us, you know you are getting the best: a state-of-the-art, high-tech machining facility and a high efficiency, versatile foundry. In addition, we have Non-destructive Testing (NDT) and NIST traceable calibrated dimensional inspection. Efficiencies allow us to compete against low-price providers, while delivering a more dependable level of quality in a shorter lead time.

Engineering

The quality products you appreciate all start here. No matter if the part is a 4-inch bushing or an enormous 20,000 pound custom bushing, it all starts with a drawing and plan. Our engineers are here to assist in the development phase of an order or even to help qualify a quote, and they’re the best in the business. Often we create an alternative design to the original specifications, in order to improve performance. Our designs incorporate features and a level of quality that meets or sometimes even exceeds that of the OEM.

Quality control

We make sure the product you receive meets our high standards. Every part manufactured in our facility is inspected and certified to match the exact specifications of the job. We use modern inspection tools, including the CMM (Coordinate-measuring Machine), which is a powerful inspection tool the size of a room that provides very accurate and detailed results.

Quality assurance

When your processes are aligned, you receive high quality and dependable results. Our quality assurance team meets weekly to review any problems or potential problems in our workflow so they can be addressed and perfected. Our ISO9001 program is managed here along with our traceability and record retention; our procedures allow us to trace any part that we produce (even years later). We can pull the work order, the date the part was poured, review the production log and confirm any possible detail that might be needed.

Alloys

- Red brass

- Leaded red brass

- Manganese bronze

- Tin bronze

- Leaded tin bronze

- High leaded tin bronze

- Aluminium bronze

- Nickel aluminium bronze

- Close grain grey iron

- Steel

- Austenitic manganese steel