Reduce energy costs and improve efficiency: stationary preheaters

Complete stationary preheater systems for flexibility and reliability

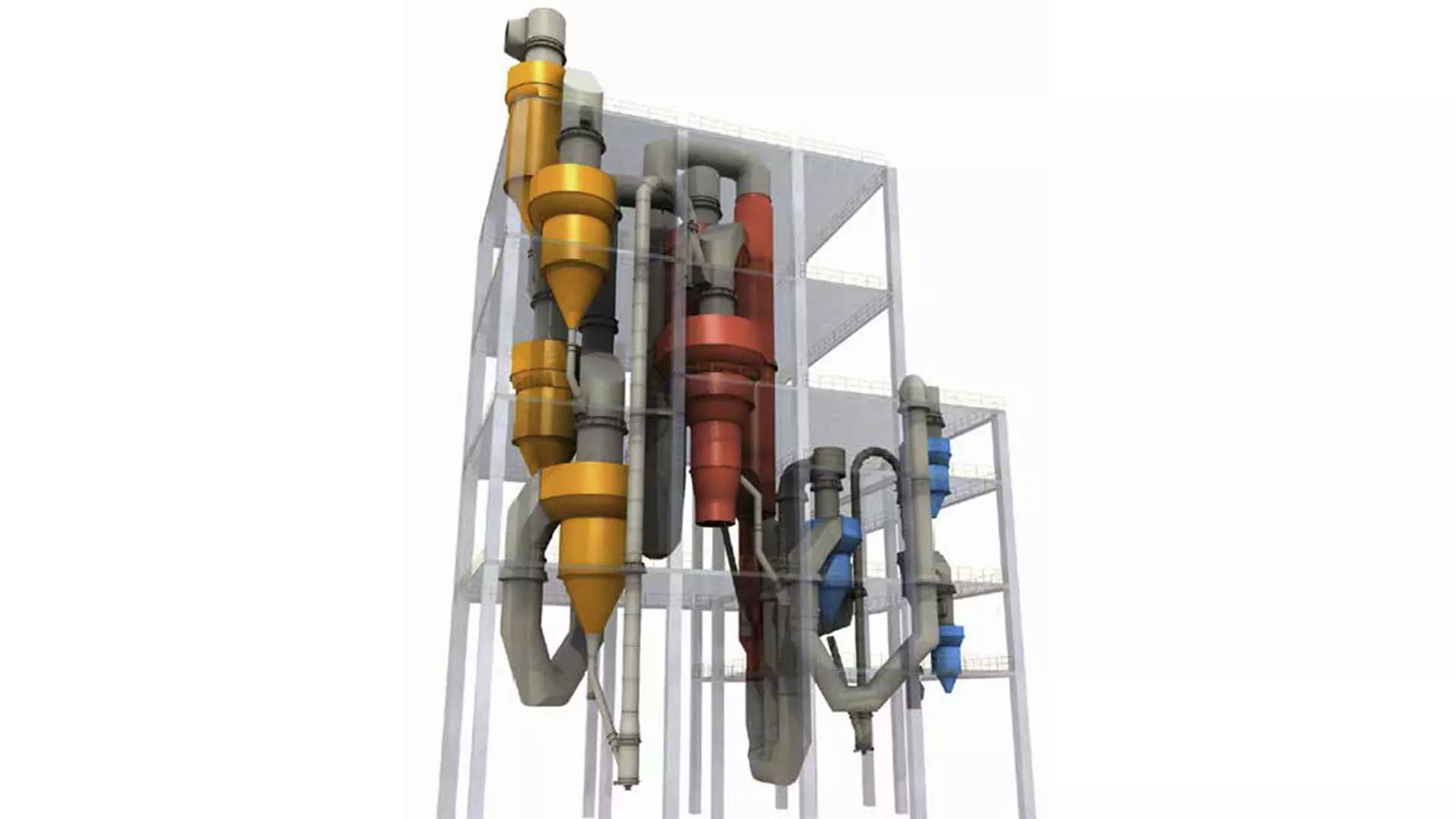

Perfect the calcination process with upgradeable stationary preheaters

Reliable equipment is essential to success in the mining industry. But given the mounting demands of environmental regulations and rising energy costs, reliability alone is no longer enough. That’s why mining operators are turning towards more efficient, cost-effective, low-energy mining solutions, such as FLSmidth stationary preheaters.

Flexible, easy to operate and extremely environmentally friendly, our stationary preheaters are changing the way mining operations around the world are approaching calcination. And thanks to our commitment to ongoing technological development, our preheater solutions will help plants keep the advantage for many years to come.

Our stationary preheaters are made for extreme durability and are designed to last, so you’ll always have a preheating solution you can count on. And thanks to intuitive design and user-friendly operation, plant managers can incorporate and use these valuable machines without the need for overly time-consuming training. And as for energy use, these preheaters not only allow for a significant reduction in NOX emissions, but they also use less fuel and less power, thus reducing the emissions associated with energy production. Additionally, the ability to effectively use solid waste fuels and other alternative fuel options without negatively impacting process stability makes our stationary preheaters some of the most fuel-flexible solutions on the market — meaning reduced costs for your business and less environmental impact overall.