For aggregates manufacturers, achieving efficient production with maximum uptime and the lowest total cost of ownership is the obvious way to keep your margins headed in the right direction. But how do you do it? In our experience, it comes down to developing and following a predictive maintenance strategy – something that has become much easier with the digitally-enabled Raptor® cone crusher ‘50’ series. The Raptor® 250, Raptor® 350 and Raptor® 450 benefit from several features that reduce and simplify maintenance, as well as advanced laser scanning – a gamechanger for both production and operations.

New features to reduce and simplify maintenance

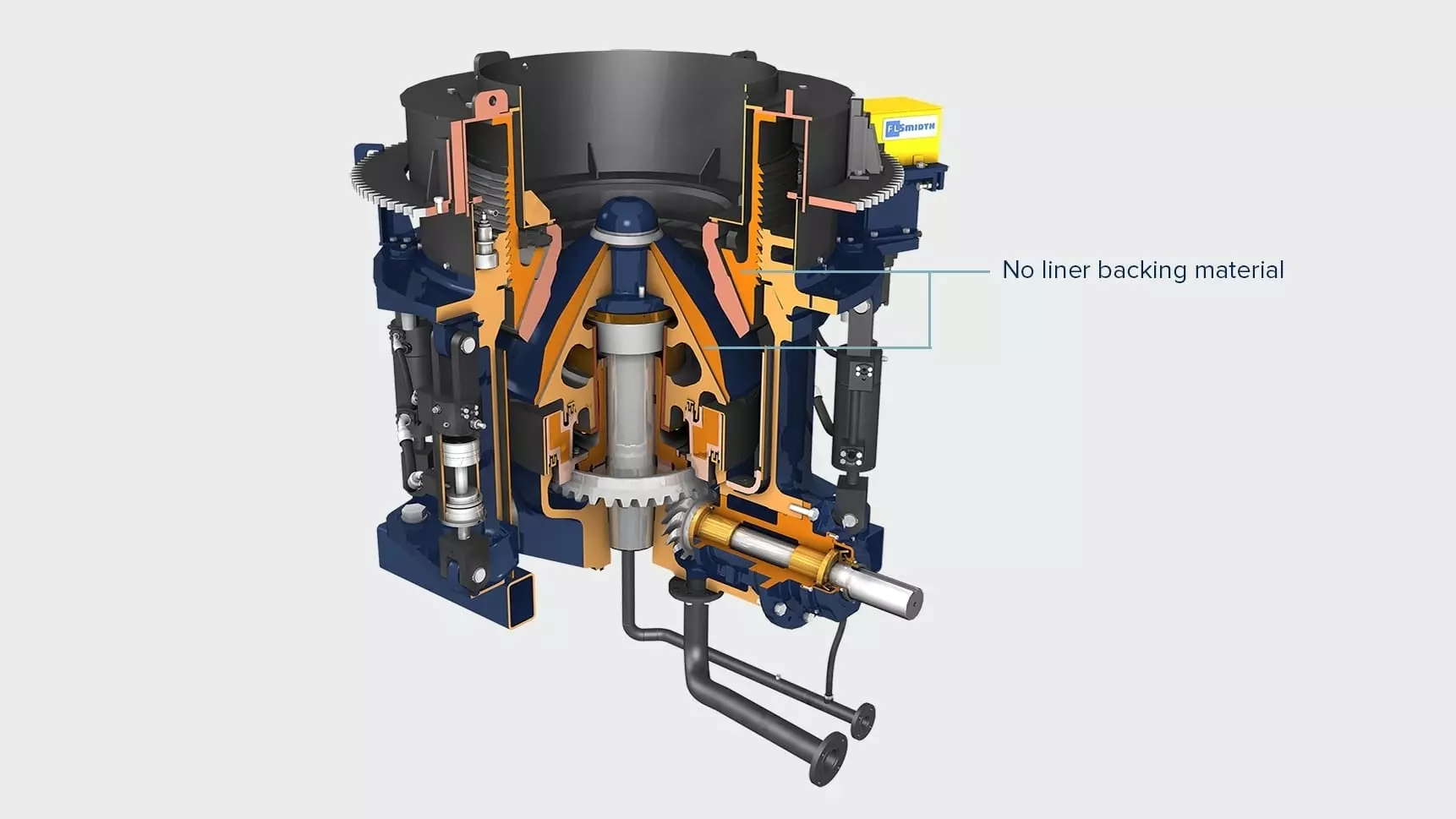

Quick, easy liner changes

One of the challenges of changing wear parts in a cone crusher is the backliner material. Other models use epoxy behind the liners to improve the fit, but every time the liner needs changing the epoxy has to be re-poured. This is both a hazardous and a time-consuming task that can add days to what should be a simple job. Moreover, the epoxy can be difficult to work with, especially in cold conditions. If it freezes, it has to be discarded.

Some years ago, we changed the design of the R250 to eliminate this process. By increasing the amount of machining we do to the liner plates, we can ensure a better fit without the need for epoxy. This saves time and money on maintenance jobs, while also improving working conditions and reducing risk. It was such a success that we have since rolled out the same design to the R350 and, most recently, the R450 model. This halves the time needed for a liner change, ensuring that the crusher can return to operations quickly and normal productivity can resume.

Integral countershaft

To enable easier movement for crushing materials through the feed opening, the countershaft box has been integrated into the three-arm mainframe. Previously the countershaft was in a separate box attaching to the main shaft, effectively adding a fourth ‘arm’ that was liable to cause obstructions and was vulnerable to wear.

The new design makes the mainframe more robust and reduces the time and money spent on replacing and stocking arm guard liners. Another advantage with this new design is that the countershaft is entirely preassembled, which makes it much easier to install. The countershaft box can be removed without disassembling the guards - saving quite a bit of time both for the removal and the re-installation.

Fewer accumulators

Accumulators are a maintenance item that requires significant attention. While many crushers have one accumulator per cylinder, we have analysed the core requirements of the 50 series and determined that only one accumulator is needed. This is mounted independent of the cylinders and gives you quicker and easier maintenance, together with fewer spare parts and fewer failure points. All this translates to reduced costs and increased uptime.

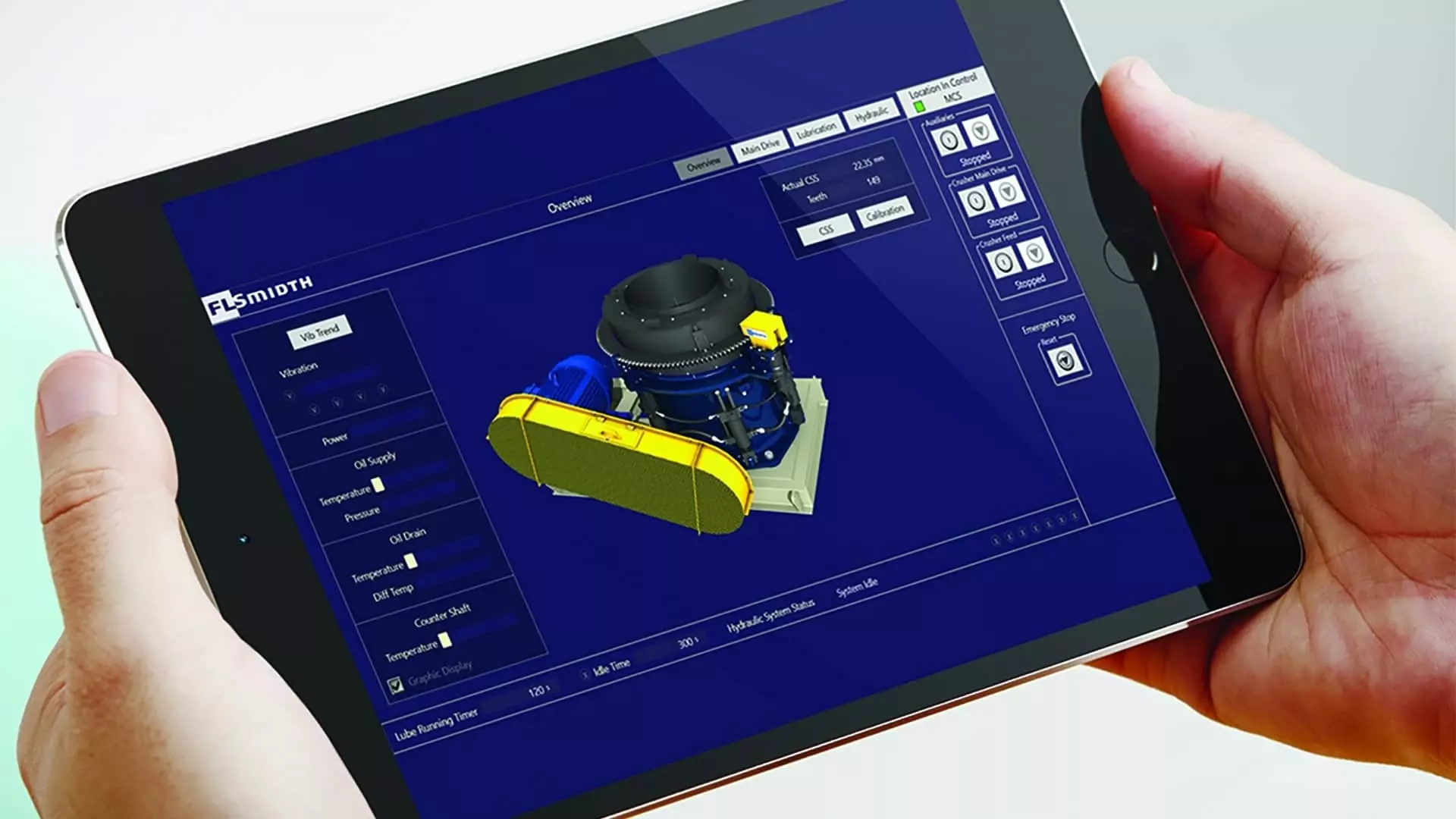

Plug and crush

Our Lube and HPU system has also been redesigned. It is now a standard size across the 50 series, which means a reduction in the cost of manufacture. And because we use a VFD to control the lube distribution, we are still meeting the precise lubrication needs of the crusher according to its size.

To make it easier to set up and get started, all the lube systems are pre-wired to Harding connectors, which means every sensor and every valve is pre-wired ready for you to plug into the control system. All it requires is an extension cord with the right plugs. This eliminates hours of wiring and is much more flexible.

Easy access

Another feature of the 50 series is the addition of lots of inspection doors in the crusher mainframe, which make it easier to inspect and even clean the crusher without having to disassemble anything. The doors are positioned to give you a good view of the arms and wear parts (when the crusher is off!). They are easy to open and large enough for you to do some light cleaning through the doors, ensuring you can keep the arms free of debris.

Game-changing data and analysis for smart operation and predictive maintenance