EXCEL's Wide Path™ Undercarriage

World's first Wide Path Undercarriage is still going strong, virtually with no unplanned maintenance during the ongoing 31,000+ hours run.

Protect your machinery, your people and your business. Since the first EXCEL™ Wide Path™ Undercarriage was installed in late 2013, this engineering innovation has proven to be a huge success—both for our customers and our business. Today we have Wide Path™ undercarriages operating in North America and South America, and they will soon be in Europe and African regions. Our customers are enjoying improved performance and increased production time between maintenance events. See our video to learn how you can save time and money.

Watch video.

Increased roll path & surface area

The extreme weight of rope shovels often causes excessive material flow in the roll path of the track pads. Our design team took on the challenge of improving the original equipment manufacturer (OEM) designs, and we came up with Wide Path™. Our larger roll path area reduces the direct stress on the track pads to create a significantly longer wear life. The Wide Path components do not require modifications to the existing side frames.

- Improves overall weight distribution onto track pads

- Produces less stress on the track pads

- Reduces wear on track pads, lower rollers, rear idler, drive tumbler and side frame guide rails

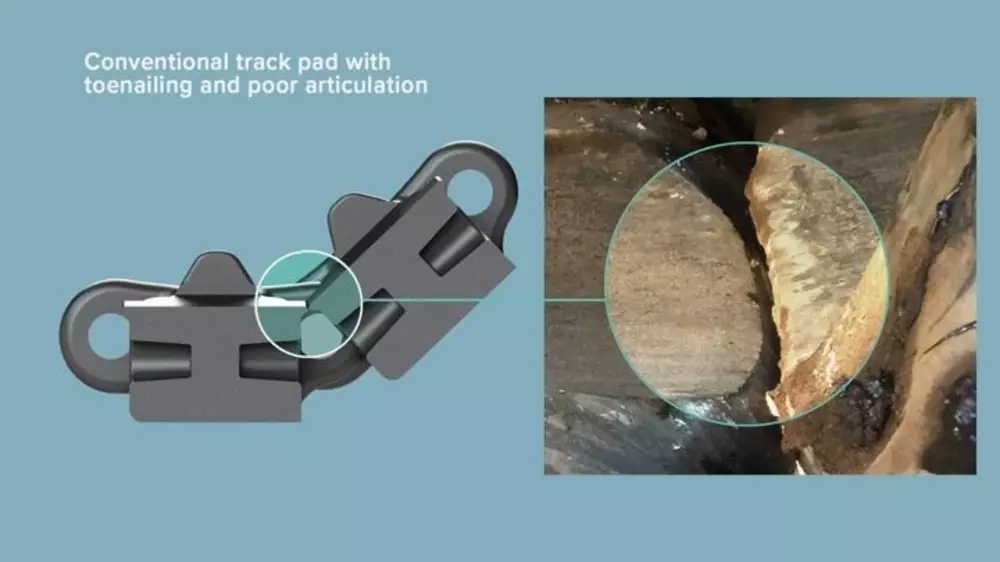

Safety concerns with conventional track pads

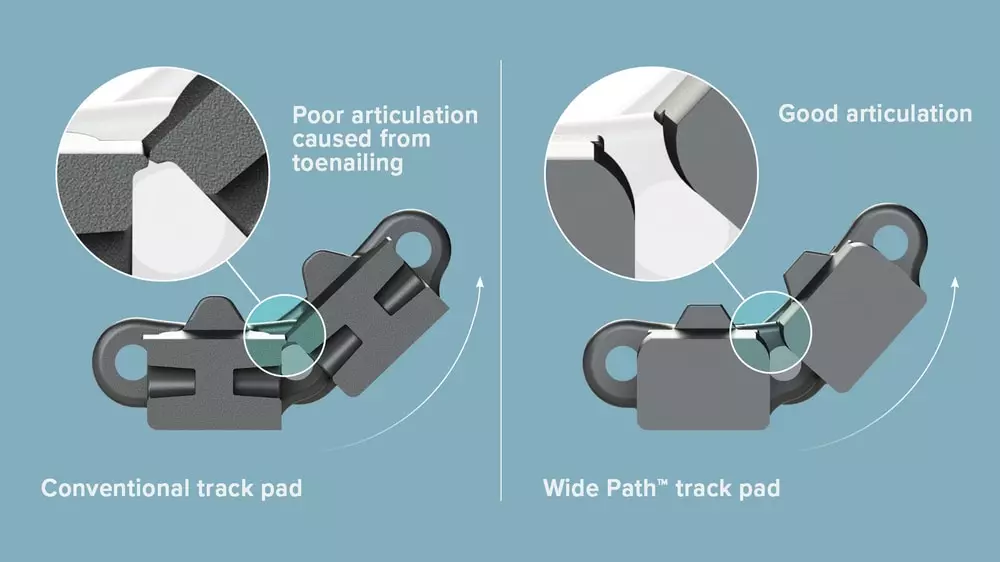

These toenails interfere with the articulation of the track pads around the idler and drive tumbler. Extreme pressure at these interference points can cause metal to break off in a violent manner. Our innovative design eliminates both toenailing and the possibility of metal breaking off and potentially causing an injury to someone.

Improves safety - Eliminates toenailing

Due to the tremendous weight of rope shovels, conventional tracks allow natural material to flow in the roll path and create toenailing. Our design eliminates this expensive and dangerous hazard, allowing good articulation.

- Prevents material loss from crushing the track pad

- Prevents dangerous fly metal created by toenail interference

- Reduces torque on pins that causes pin eye elongation

Improve Performance leads to - Large cost savings

Improved performance

As conventional track pads wear, they begin to bend away from the ground across the width of the pad. Bending in this way causes stress on the pins and interference between the pad and the car body. Our design has a thicker internal structure to minimise bending. Without toenailing and track pad bending, the track articulation is more smooth and the quality of performance for the entire system is increased.

Decreasing the required maintenance and increasing the performance of the undercarriage system allows maintenance personnel and operators to have more confidence in the entire shovel. They will be able to focus on the job at hand instead of frustration over equipment issues.

Contacts

Abhay Pathak

Abhay.pathak@flsmidth.com

Navin Ramakrishnan

+91 98403 91218

Navin.ramakrishnan@flsmidth.com