-

Engineering at work: How we used our ring gear innovation to improve a mining operation in Chile

In our 140 years of history, we have challenged conventions and explored new opportunities, providing valuable solutions for our customers' operations, through our expert knowledge and developing the most advanced technologies that set us apart. In line with these guidelines, our purpose today is to keep on building the mining industry for a sustainable world, facing the challenges of the future. This is possible through a new strategy showing a clear path to become an even stronger player in the mining market, improving our profitability.

But our most outstanding feature is that our specialists combine years of experience on engineering, introducing important updates in design and modernising existing equipment to guarantee security, quality, reliability, and productivity to our customers.

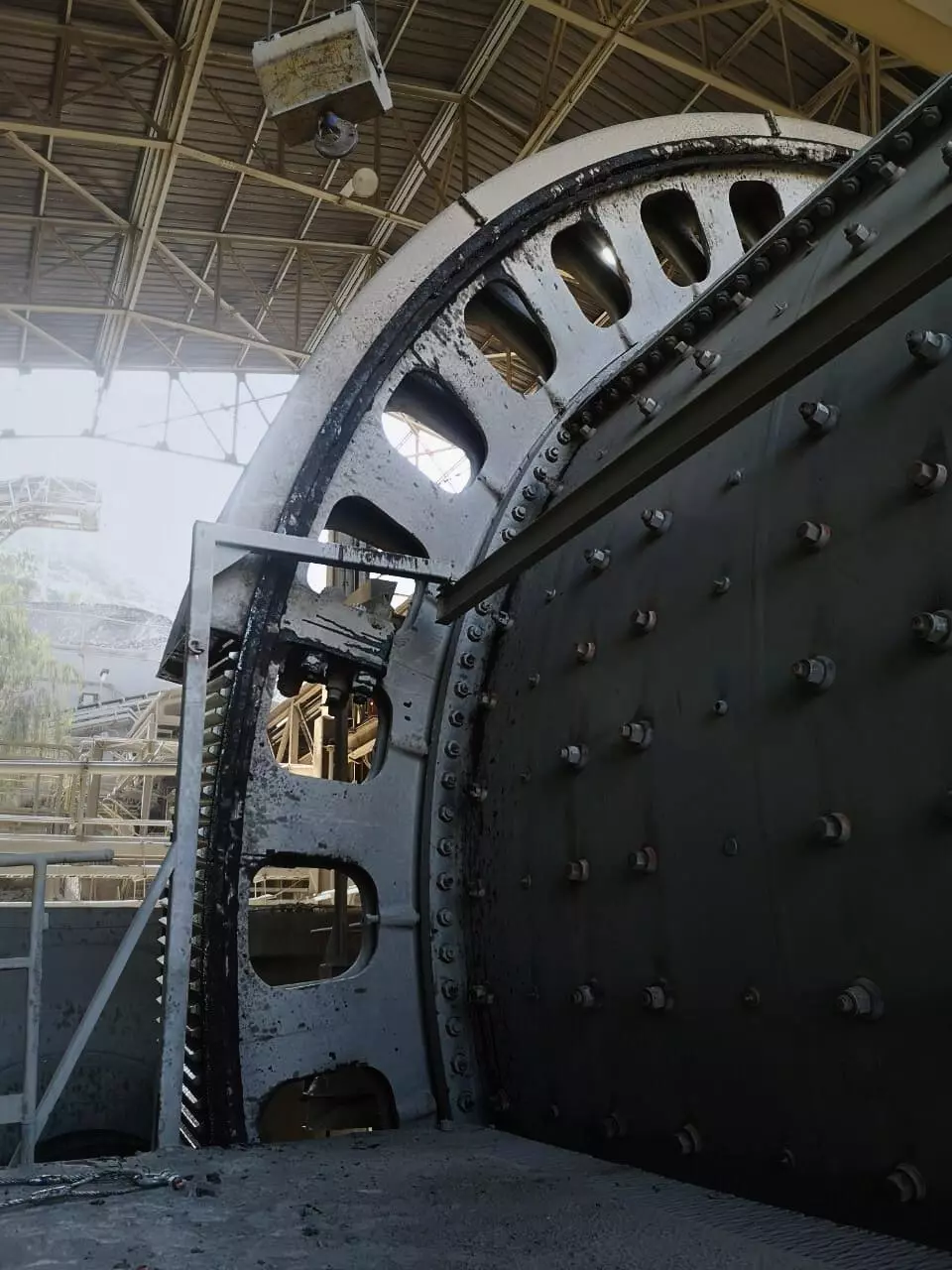

Saving a faulty casted ring gear on a Chilean mining operation

"We were on the customer's radar due to recommendations they received for the installation of liners in mills and the successful implementation of ring gears we did for another company," says Alvaro Alvarado, FLSmidth's Site and Service Sales Territory Manager.

Solution: Global experience and expert knowledge

To renew the ring gear, we presented a consolidated offer encompassing both supplying materials and providing services, considering the stages across the value chain, such as engineering, development, manufacturing, assembly, and commissioning the spare part.

Then, our specialised engineers carried out very meticulous work, through on-site measurements and monitoring of the protections of the ring gear to track the evolution of the cracks. In this stage, we highlight the active participation of our team from Salt Lake City, USA — whose contribution and excitement made us meet the tight deadlines of the job.

"There was uncertainty because we didn't know the critical dimensions and operation of the mill made by another company, therefore we had to make a more detailed analysis of the working conditions. Despite this, we adhered to the deadline set to finish the implementation of a new ring gear, being one day ahead of the proposed schedule and the customer’s planning, which was beneficial to the performance," Alvarado states.

In turn, our Head of Mining Aftermarket Sales South America and the person in charge of the project, Nilton Herrera, stresses the idea that this work represents a key success for the company because we installed an FLSmidth spare part into a piece of equipment from another company in the market.

"We had to perform hard engineering work designing a ring gear that fits the machine, which we successfully achieved. In this line, we accomplished other goals related to this job, such as increasing our market share in ring gears, and continue supplying spare parts, which opens the door to supply ring gears across the mining industry," he indicates.

Where is the benefit?

Because it is made of a forged material, the risk of having defects — such as pores in the material, which is usual in ring gears made out of casted material, and other casting defects — is reduced. "This way, many problems, or issues with the material after being installed are avoided, such as what happened with the original ring gear that experienced premature failures during operation," our Site and Service Sales Territory Manager states.

Structured ring gear: our innovation

Considering that more than 90% of ring gears in the market are casted, at FLSmidth we went further and stood out for our manufacturing process. This way, we provide the customer with a structured ring gear, that is, one that is not cast and has a rim. This means structural steel and a forged ring, which are welded together and are a different process compared to casting.

From A to Z: supply across the whole value chain

Although engineering and manufacturing were challenging, the customer was very satisfied with our job and service performance.

“In FLSmidth we have the necessary capacities to implement this kind of solutions, as the one developed for this important mining operation, covering all the stages, from A to Z, across the whole value chain,” says Nilton Herrera, FLSmidth’s Head of Mining Aftermarket Sales South of America.

"There, we applied all the lessons learned during the manufacturing of the first one. It was a very valuable learning we will continue applying to improve our customers' productivity. On the other hand, in terms of security, we fulfilled all the standards, because we had no accidents during the installation", Alvaro Alvarado says.

Finally, we highlight the close collaboration relationship we had with our customer to achieve the successful result we had. In this line, we emphasise the application of our "FLSmidth Service Experience" (led by our Site & Service Sales area), based on a value proposition through which we seek to provide our customers with specialised support through simplifying our operational model to reduce risks, improve efficiency, and guarantee a more robust and excellent execution of our services.

With this successful case, we can tell we continue strengthening our position as the comprehensive vendor of process and product technology with world-class sustainable offers across the plant, supporting our sustainability goals and the green path set by our customers.