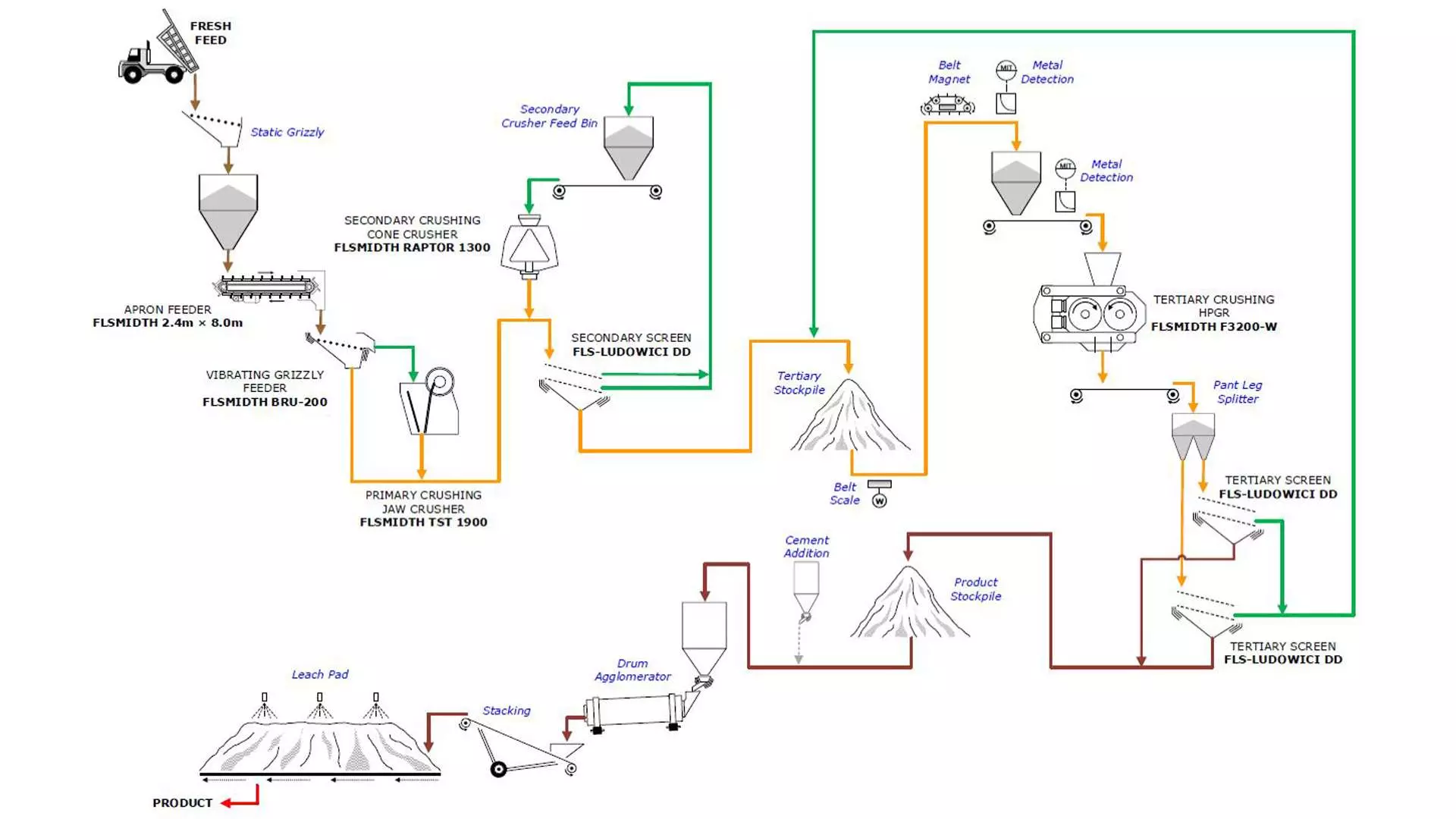

Ivrindi Gold is a new mining and enrichment project in Western Turkey owned by TÜMAD Mining Industry and Trade. With ample resources available, the company wanted to optimize its output by investing in equipment that could deliver a large throughput. Their feasibility study indicated the heap leach process would be suitable for this site and Ivrindi Gold began searching for the right equipment for the job.

In the heap leach process, gold ore is crushed to a -6 mm product size, drum-agglomerated and stacked onto a leach pad, where it is saturated with a leach solution that dissolves the precious metals and carries them to the pad below and on into the ADR plant. This is a cost-effective process, provided the required particle size is reached and the leach solution can access the gold within the product. Otherwise, you risk wasting valuable materials.

High pressure grinding for efficient gold recovery

Choosing a technical partner

Having established the desired technology, Ivrindi Gold began the process of finding the best possible partner. It wasn’t just the HPGR. The contract also included a jaw crusher, cone crusher, screens and other equipment. Ivrindi Gold wanted to work with a supplier who could deliver a full flowsheet solution – and one where all parts performed equally well. This significantly narrowed the field.

After looking at proposals from other equipment manufacturers, the decision came down to trust. Who could Ivrindi Gold trust with this project and their future profitability? Having developed a good relationship with our regional team, Ivrindi Gold decided to place their trust in FLSmidth.

It may have seemed quite the leap of faith: the biggest HPGR ever built for a gold heap leach operation; the first F-Series HPGR we had ever built, and the only HPGR operating in hard rock mining in the region. But it was a leap the team at Ivrindi Gold were prepared to take because they trusted us to make a success of it. We committed to being onsite throughout plant erection, start-up and commissioning to ensure we wouldn’t let them down.

When is HPGR the right solution?

Defining the flowsheet

The compressive force of HPGR enables Ivrindi Gold to achieve the desired product fineness of -6 mm, which would be very difficult to achieve with conventional crushers. With that much of the flowsheet decided on, the rest of the equipment could be determined. In all, FLSmidth supplied:

- 2.4m x 8.0m apron feeder

- BRU200/450 vibrating grizzly

- Primary crusher – TST 1900 Jaw Crusher

- FLSmidth-Ludowici 3.6 x 7.3 m double-deck screens (qty. 3)

- Secondary crusher – Raptor 1300 Cone Crusher

- Tertiary crusher – F3200-W HPGR

In addition to the 12 months of site service mentioned above, we also provided training for site personnel. A stock of major wear and spare parts is also kept onsite to ensure the plant is well prepared for any eventuality.

HPGR and plant design details

- Model: F3200-W HPGR

- Roll dimensions: 2.2 m dia. x 1.5 m

- Installed power: 4000 kW (2 x 2000 kW)

- Ore type: gold ore with high quartz content

- Design capacity (fresh feed): 1139 tph

- Feed size: 45 mm x Ø

- Product size: -6 mm (screen underflow)

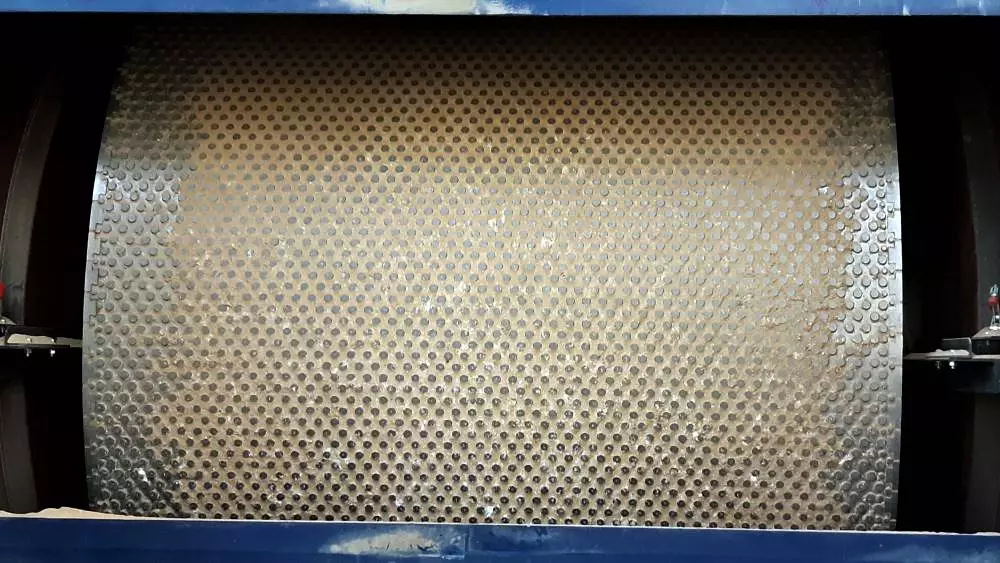

Built to last

A compact mineral layer builds up on the studded roller surface, protecting the rolls without affecting performance, and thus extending the wear life of this critical component.

Snowy conditions

The winter of 2018/2019, when this project was being undertaken, was a white-out. Snowfall made access to the site very challenging, and working conditions even more so. Added to this was the fact that this was the very first – and also the largest – F-Series HPGR we had ever built. The schedule was tight, with no wiggle room built in for development work. And yet the machine was engineered, detailed, manufactured and delivered within the project schedule – a testament to our strong, regional project team headquartered in Ankara, Turkey, and the combined operations and engineering efforts of FLSmidth in Austria and the USA. A key factor in this success is that the frame design of the F-Series lends itself to easier shipping and assembly.

Meanwhile, the site team wouldn’t let a mountain of snow put progress off course. They were able to get the majority of the HPGR assembled on site in about 30 days, in spite of the poor weather conditions.

Running to order

“FLSmidth has been a consistently reliable and dedicated technical partner, not only in terms of the technology supplied but also in the way they prioritized customer service throughout this project and continue to do so with services and spare parts,” says Mr. Hasan Yucel, General Manager of TÜMAD Mining Industry and Trade.

As a direct result of the successful installation and operation of the F3200-W HPGR at Ivrindi Gold, two identical units were sold to a project in Russia in 2020.