-

EXCEL™

Delivering quality parts and unparalleled service

Through continuous innovation we have improved on the original OEM components for cone and gyratory crushers to increase wear life, durability and ease of use. FLSmidth is recognised as a leading global provider of optimized replacement parts for mining and aggregates equipment. Our product brand Excel™ has earned a formidable reputation for producing high quality replacement parts, integrity in conducting business, and reliability to meet even the shortest deadline.

Crusher spare parts

We design and manufacture steel, iron and bronze replacement parts, as well as hydraulic cylinders and nearly any other part needed to keep comminution equipment running smoothly. Our offerings include high performance spare parts for most crushers.

Metso® HP™ Cone crusher

Metso® MP™ Cone crusher

Symons® and Gyradisc® cone crusher

Omnicone® Cone crusher

Sandvik® Hydrocone™ and Superior™ crusher

Allis-Chalmers®/ Svedala® Hydrocone crusher

Telsmith® Cone crusher

Extraction equipment spare parts

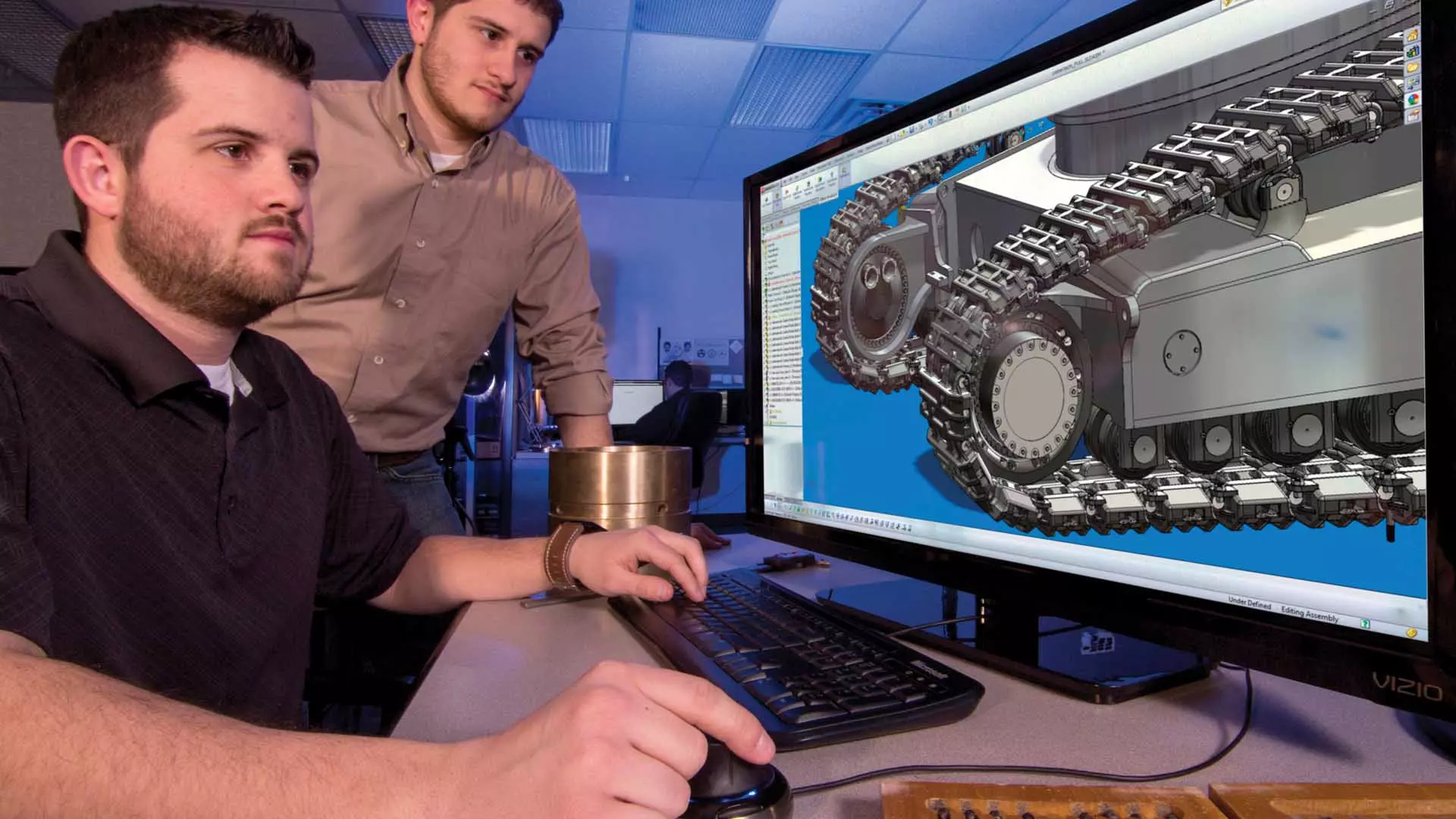

We manufacture quality steel, iron and bronze replacement parts for large-scale open pit mining equipment such as bushings and pins. We now also offer customised wide path undercarriages for many models of excavators and rope shovels.

P&H® Electric Rope Shovel spare parts

Komatsu®/ Demag® Hydraulic Excavator parts

Hitachi® Hydraulic Excavators spare parts

Liebherr® Hydraulic Excavators spare parts

Bucyrus® Electric Rope Shovel spare parts

Wide Path™ Undercarriage for P&H® and Caterpillar® Electric Rope Shovels

We focus on quality at every step from analysis and testing, to innovation and manufacturing, to logistics and training. Collaboration, innovation and integrity are key components of every part we sell.

New spare part designs start with performance and durability research. We diagnose shortcomings of the OEM components using in-depth failure analysis and destructive testing. Based on our findings, our metallurgical specialists create solutions. No new design is complete until we are proud of the results that you can routinely expect. All this is backed by our dedicated customer support team because we want to help you succeed.

Quality redefined

We inspect and re-inspect every part that leaves our dock because we know that our parts are used in mission critical equipment and that your success depends on our quality control. Our staff of skilled craftsmen strive to make every part perfect in every way. Our strict metallurgical standards in our foundry, precision turning and machining processes and inspection department all focus on our customer’s needs.

Passion for excellence

From the technician in the foundry pouring castings to the customer support representative taking your order, we are geared toward exceeding your most demanding needs. We build quality and reliability into everything we do.

Learn more about EXCEL™ high performance parts for compression crushers

See high performance replacement parts for mining and aggregate equipmentA brief history of EXCEL™

Founded in 1929 under the name Excel Brass & Machine in Pekin, Illinois, the company specialised in manufacturing small brass bushings and fittings. During the 1970s, the company changed its focus towards the production of bronze wear parts for the active mining industry in the Midwest United States. This development was motivated by the fact that mining companies had difficulties sourcing OEM parts for their equipment.Since the very beginning, the company philosophy has been to provide high quality parts and unequalled service to the end-users of mission critical heavy equipment. In combination with the ability to meet even the shortest deadlines, Excel™ is by many customers perceived as the place to go for replacement parts for the mining and aggregates industries.

Today, Excel is renowned as a full-line provider of high performance crusher replacement parts, mill lift inserts, undercarriage components for many models of shovels and a growing line of replacement parts for large-scale open-pit mining equipment.