-

MissionZero in Cement

Increase your commercial competitiveness and move towards a zero-emissions cement plant by 2030. The solutions and services you need are here.

Zero emissions

Reduce carbon emissions from fuel burning and reduce process emissions from clinker. Explore the solutions that moves you towards zero emissions by 2030.

Calcined clay

Reduce process emissions by up to 40% with our clay calciner system and get a cost-effective quality product that meets your expectations for strength and colour.

Process control and optimisation

Reduce your emissions by optimising your processes; minimising your fuel consumption and improving your clinker factor.

Lower NOx emissions

Read more

Carbon Capture

To accelerate the green transition of your business, we have teamed up with leading carbon capture experts to adapt several different CCUS solutions to the cement industry.

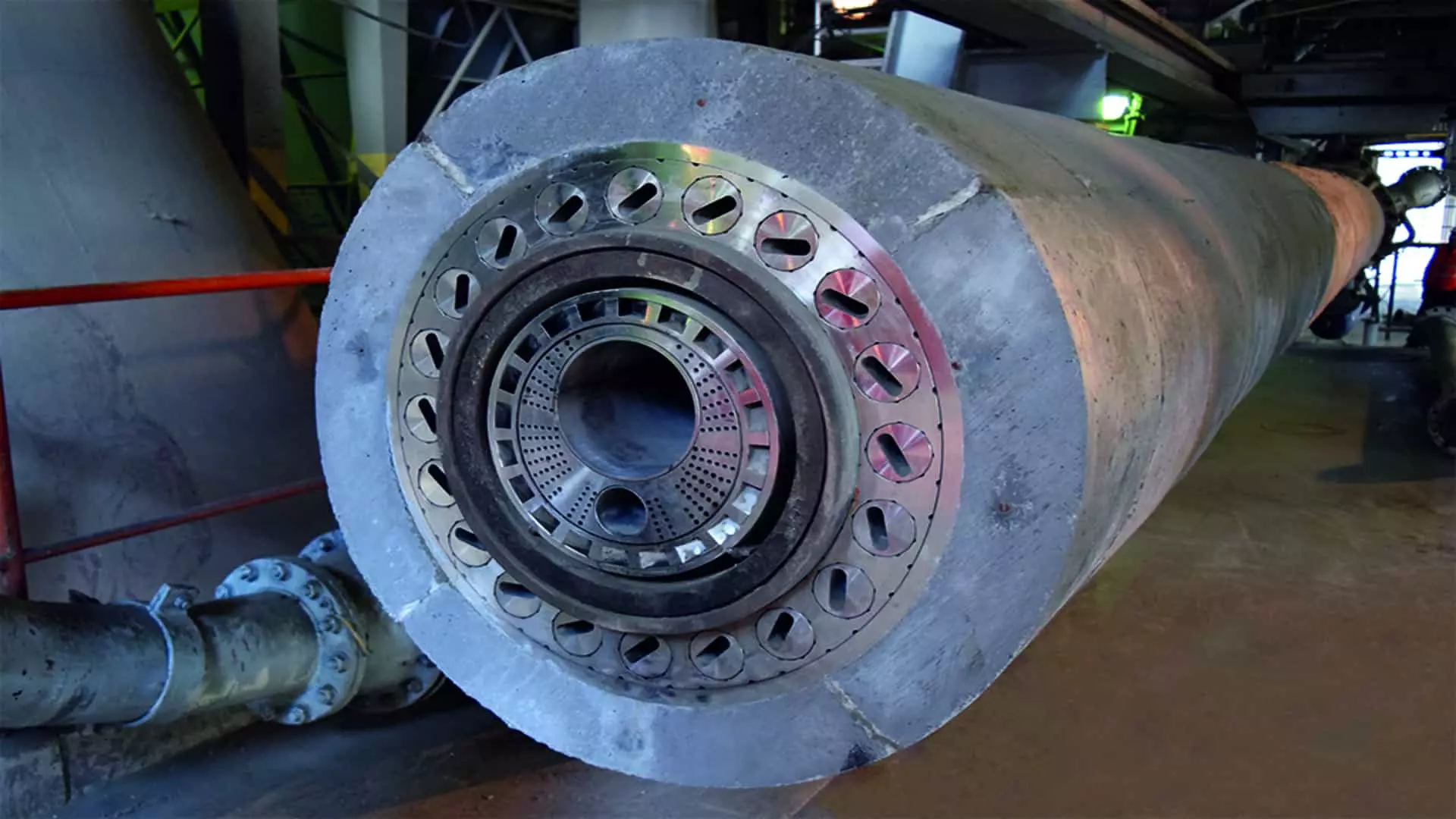

100% fuel substitution

Substituting fossil fuels with alternative fuel in the kiln reduces the net carbon footprint. Our solutions allow for 100% fuel substitution, including burning of waste.

From waste to energy

By turning waste into energy, you can help your local community manage waste and reduce your own energy costs at the same time. We offer several solutions.

Efficient alternative fuel firing

Read more

Zero waste

Reduce your environmental footprint by using less energy and fewer materials. Increased energy efficiency to makes plants more sustainable and profitable.

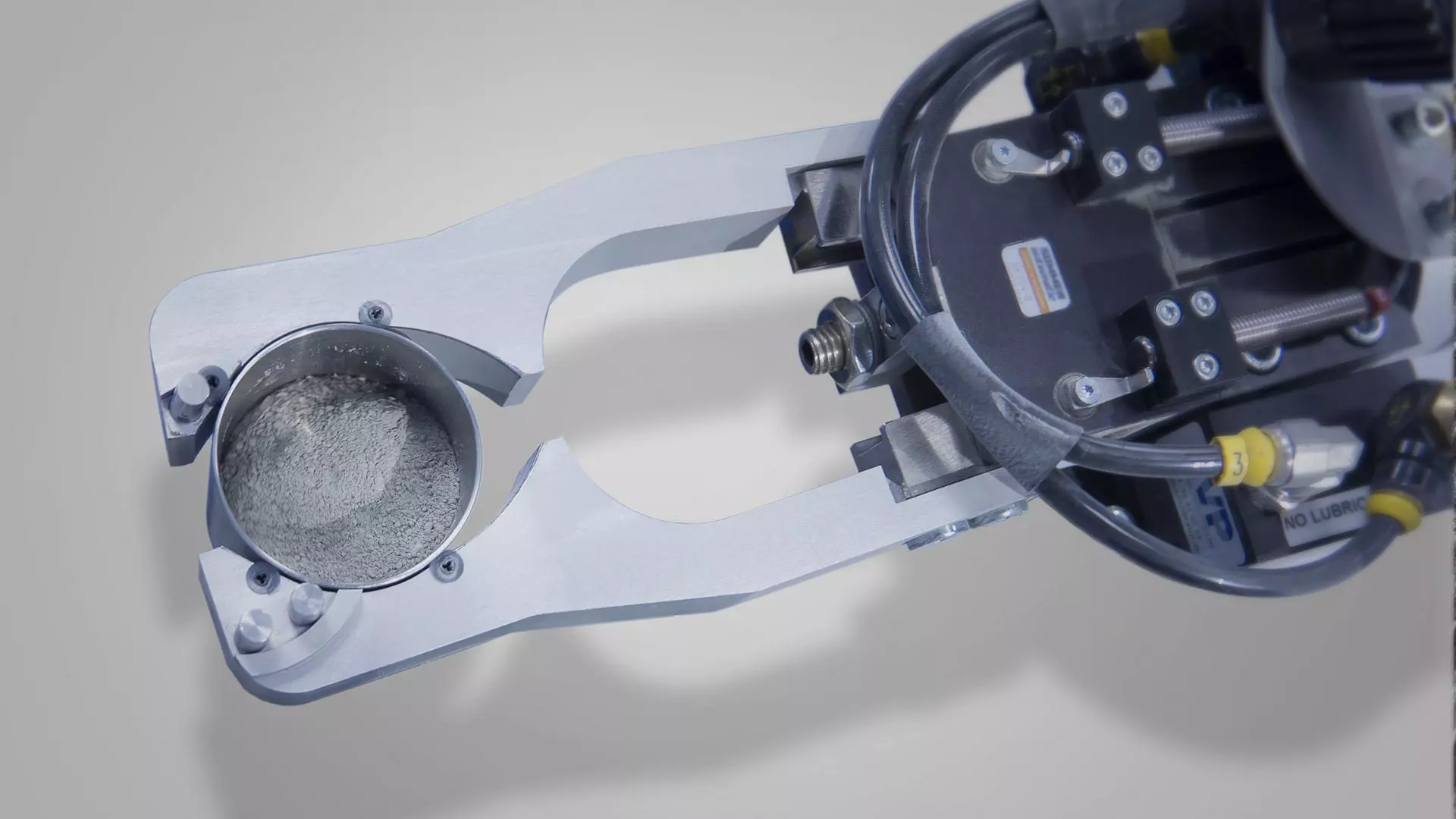

Energy efficient milling

Read more

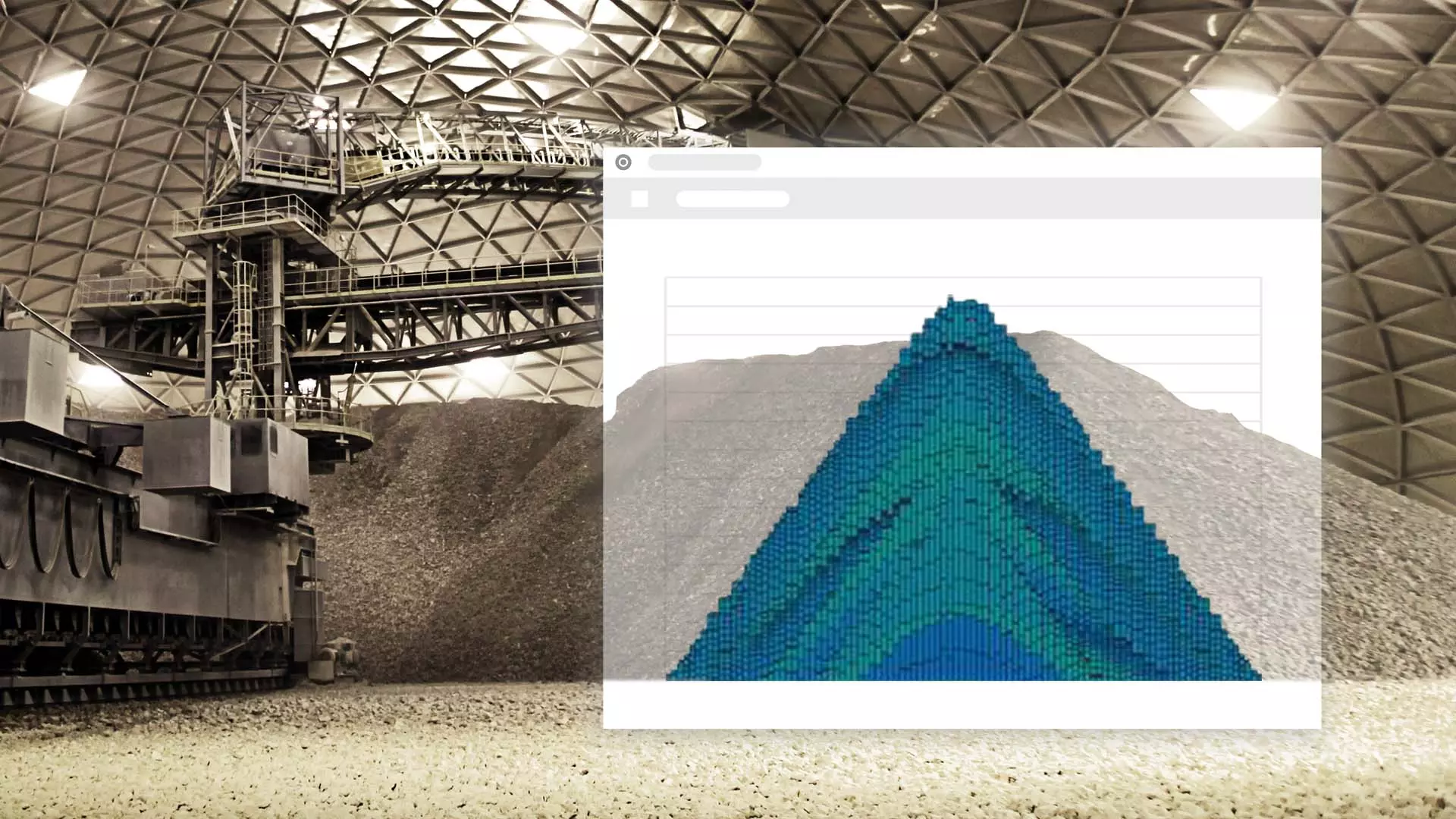

Reduce waste of material with quality control software

Read more

Optimise production and reduce emissions

Read more

Stories