-

MissionZero in Mining

Our solutions for water management and emission reduction will make mining more sustainable and improve your commercial competitiveness.

Discover the interactive mining flowsheet at www.MissionZeroMine.com.

Zero water waste

Sustainable water use and smart tailings management cut risk and increase safety. It is often the number one concern for investors, authorities, and local communities alike.

Tailings management

Every mine site has unique considerations for tailings management. Explore safe and sustainable solutions for your site.

Water reuse

Reclaim up to 95% of your process water for re-use with our AFP-IV® Colossal filter press. It cuts costs and reduces your environmental impact.

Zero emissions

Increase your energy efficiency in energy-intensive mineral processing and reduce emissions from fossil fuels and transportation in all your mining operations.

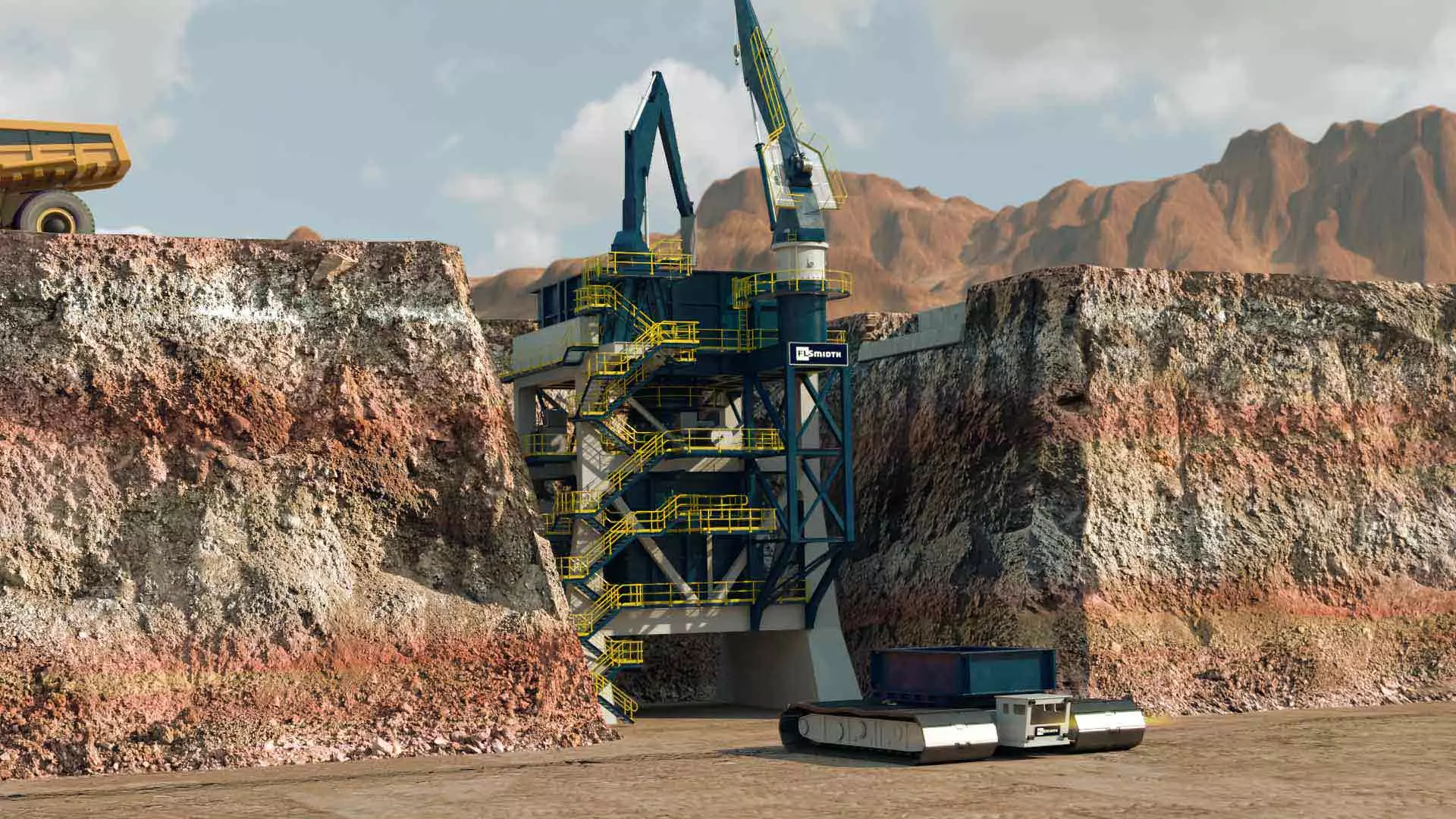

A greener footprint

In-pit crushing and conveying solutions can cut truck fleets – and costs – as well as increase the overall productivity of your mine.

Reducing emissions and footprint

Rapid Oxidative Leaching (ROL) can develop mineral deposits containing arsenic for recovery of copper, gold, and silver. Refractory ores are processed at low temperatures, saving energy and cutting risk of arsenic pollution.

Zero energy waste

Manage energy costs and reduce energy waste, especially from energy-intensive comminution and unnecessary truck fleets to make mining more sustainable.

Recover more minerals using less energy

Read more