Substitute your calciner fuel with a wide range of alternative fuels

Waste to energy and the freedom to choose lower-cost alternative fuels

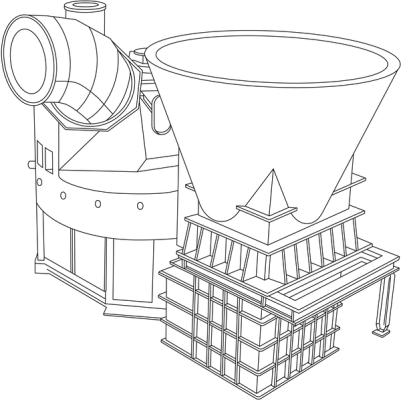

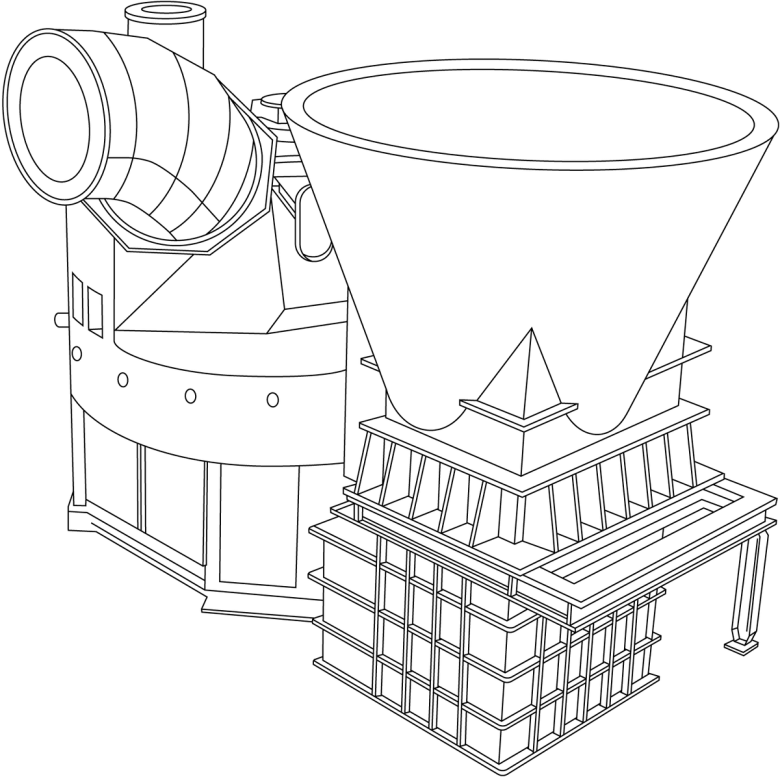

From sludge and grains to whole truck tyres, our HOTDISC Reactor gives you the potential to burn a wide range of alternative fuels, without compromising on energy efficiency or kiln performance

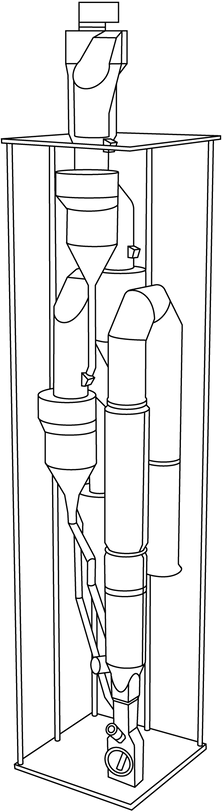

The HOTDISC alternative fuels solution can handle a wide variety of solid waste in sizes up to 1.2m – from sludge or grains to whole truck tyres. – without the need for expensive shredding of lumpy waste material or pre-drying. This makes the transition to alternative fuels much easier and more cost-effective, especially in regions that lack a developed waste processing industry. And because you are no longer tied into any single fuel supplier or supply chain, the HOTDISC improves your position on the fuel market.

The HOTDISC’s use of clinker cooler tertiary air and preheated raw meal, along with alternative fuel, ensures virtually 100% energy efficiency. The HOTDISC is designed to achieve a calciner substitution rate of 50% up to 80% of the calciner fuel, and potentially even higher. Results vary by the specific plant conditions and fuel specification. With over 20 years of documented results, we can confidently predict the performance you can expect at your plant.

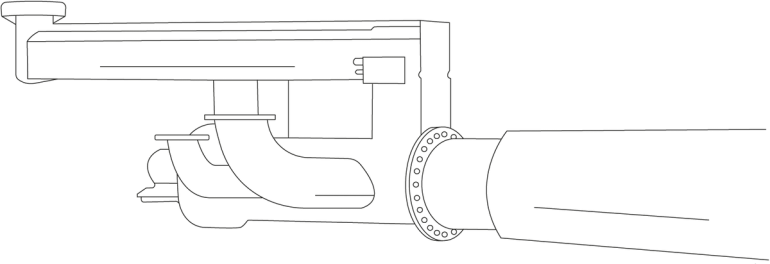

The variable speed drive provides the ability to have a fuel retention time of 3 to 45 minutes inside the HOTDISC. This reduces the adverse effects of unburned fuel in the kiln inlet and provides complete control of the process. Consequently, the HOTDISC eliminates operational disturbances such as cyclone blockages, the need for extra cleaning in the riser duct and emissions of unburned components. These disturbances typically occur if combustion and sulphur circulations from unburned fuels cannot be controlled.

Since the introduction of the HOTDISC in 2002, we’ve continuously improved the design of the system. The latest generation provides maximum fuel flexibility, process control, capacity and durability. The HOTDISC is available for new kilns and for retrofit into existing kiln systems.

What do you want to burn?

Refuse derived fuel (produced from municipal garbage), loose or compacted Tyres (whole, shredded or cut into pieces) Paper sludge Municipal solid waste Old car fragments (upholstery, dashboards, etc.) Dried sewage sludge