-

RFC Upscaling

Not only fast recovery of valuables, but at enhanced grades - REFLUX® Flotation Cell (RFC™)

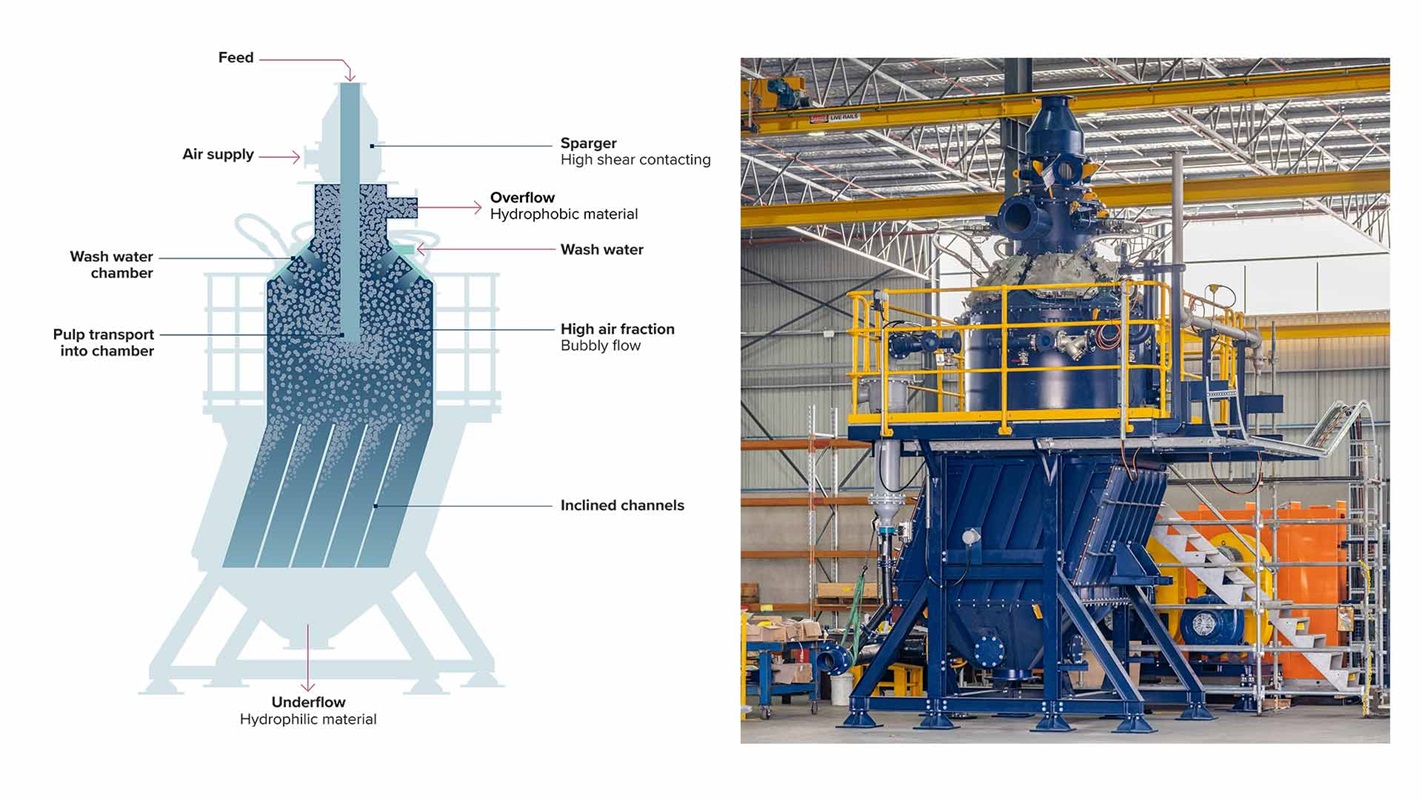

The University of Newcastle in collaboration with FLSmidth has developed a novel flotation technology utilising an inverted fluidised bed, arranged above a system of inclined channels, to enhance the hydrodynamics of flotation. The froth-less system allows for stable flotation, enhanced gangue rejection, and quicker kinetics – pushing the boundaries on concentrate grade, recovery, and throughput well beyond what is possible with conventional open tank systems.

REFLUX® Flotation Cells - maximum particle recovery

The RFC consists of a main vertical vessel positioned above a system of inclined channels. The inclined channels enhance the segregation between the bubbles and downward flowing liquid, thus preventing the bubbles from leaving out the base of the cell, even at high tailings rates. Feed and air enter the cell via a central sparging system to expedite the flotation kinetics. The overflow product emerges through an annulus surrounding the sparger system, while the tailings discharge via the zone below the inclined channels. A plenum chamber encloses the top of the cell, supplying clean fluidisation water for counter-current washing of the rising bubbles with a positive bias flux to promote effective gangue rejection.

The RFC can be used as a first stage fast flotation technology. This single stage rougher approach aims at maximizing throughput and particle recovery using up to a 10-fold increase in conventional volumetric feed flux. The RFC can also be used in a second stage de-sliming or cleaning application. The cleaning stage utilizes the inverted fluidized bed approach to apply fluidization wash water to deslime the flotation concentrate free of entrained gangue particles.