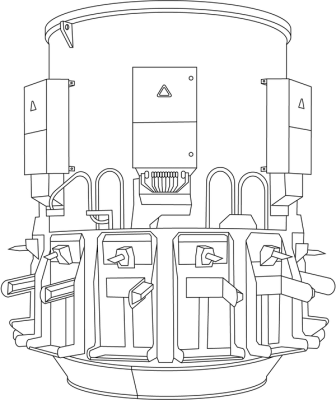

Flexible and efficient electronic rotary packers for valve bag filling

Rotary packing machines for cement and granulated materials

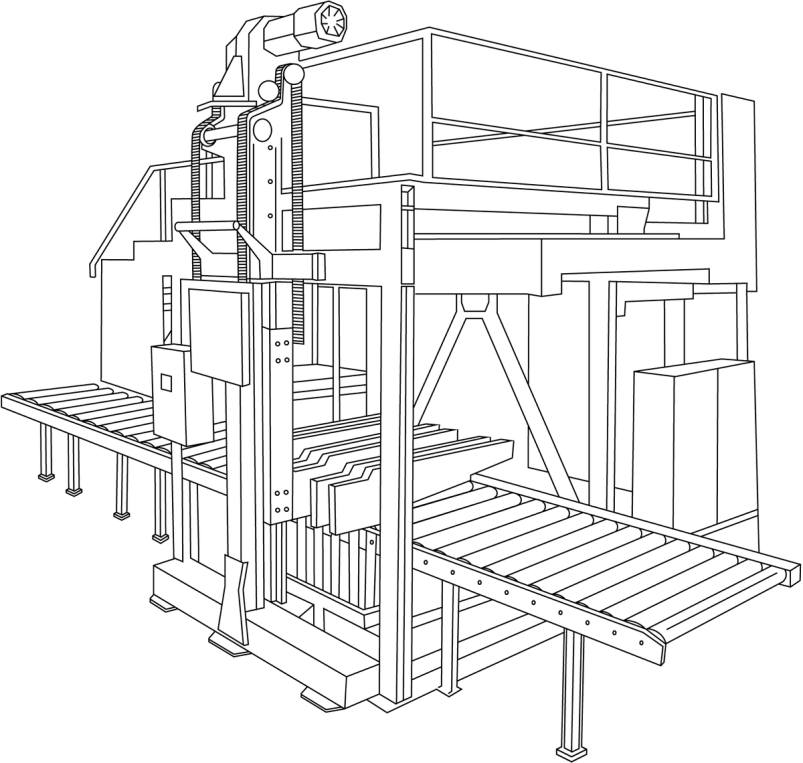

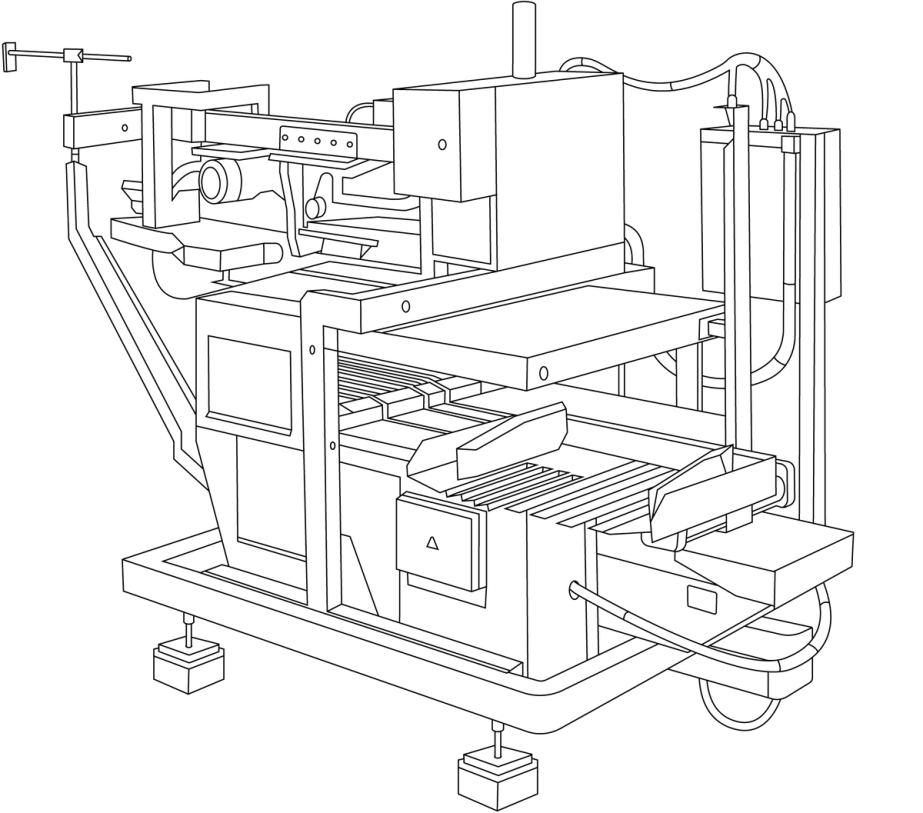

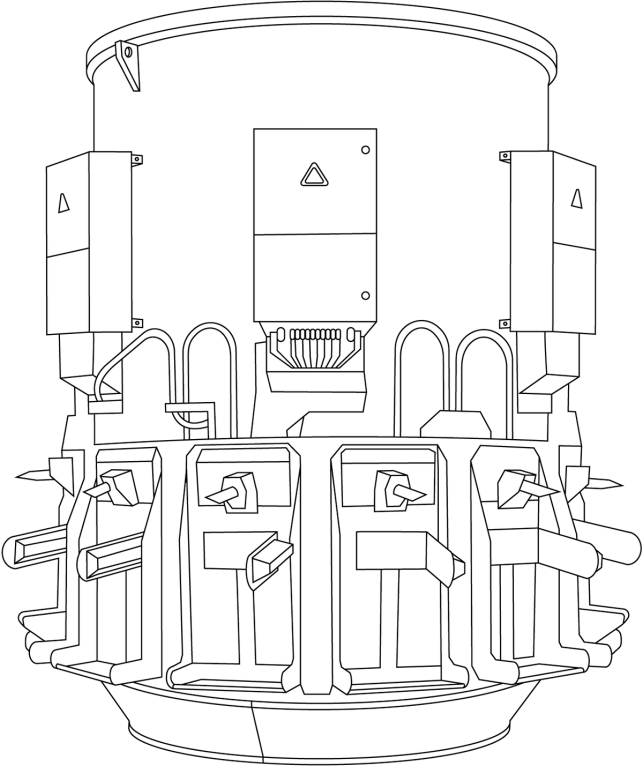

Rotary packers have come a long way. Where once every machine would have to be operated by a human placing bags on spouts and manually controlling the fill level, today’s machines are entirely automated. We’ve played a major part in that evolution – as the first manufacturer to develop a microprocessor-based controller for filling and weighing units on packers, and then as the first to introduce the electronic rotary packer. Our latest innovation is the new GIROMAT® EVO rotary packer generation. Its compact and modular design is both flexible and expandable, up to 16 spouts and with an output up to 4800-5000 bph of 50 kg and 5300-5600 bph of 25 kg .Designed for bagging cement and other building materials, it comes in a range of configurations, such as: Impeller or fluidizing (air type) filling technology according to product; Bag clamping device for glued and stitched bags; suitable for various bag construction material; Rapid discharge for quick product change-over; and bag sealing system based on ultrasonic technology.

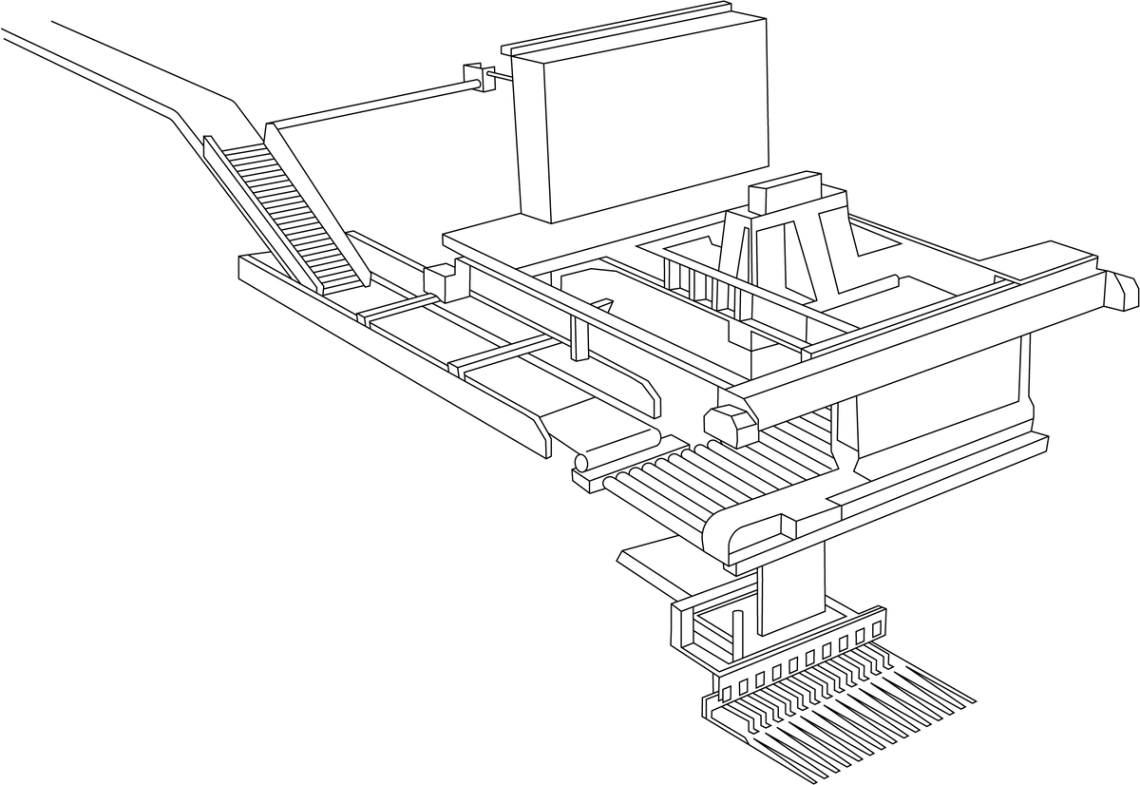

For easy installation, Ventomatic® packers are composed of a number of preassembled modules, all of which are prepared and tested before delivering. These modules are quickly and easily mounted on the central tank of the packer during installation. We make it really simple: the pneumatic connector plugs and electric rapid connectors are numbered so you know exactly what fits where. This modular design enables you to put the packer into service with a reduced number of bag filling units. When you need to increase production, you simply add more filling units.