Easy and safe automated free lime determinations

QCX Automatic Free Lime Analyser for accurate results

In a fast-pace and demanding industry, we know exceptional product quality, coupled with low energy consumption, is vital for successful cement production. Free lime concentration in clinker is a key factor in cement production. That’s why we’ve used the latest technology to develop the QCX FLA100 Automatic Free Lime Analyser – to accurately and quickly analyse free lime. Excess free lime in your clinker has an adverse effect on both product quality and process efficiency. Too much free lime and your product suffers from volume expansion, longer setting time and reduced strength. You also want to achieve maximum reactivity in your kiln to reduce energy consumption. Close monitoring of free lime levels allows you to keep a steady operating point, optimising thermal consumption. And when you operate at increased reactivity you can reduce raw meal grinding – another valuable energy saving. The analyser uses the well-known principle of ethylene glycol reaction with calcium oxide. CaO concentration is then determined by the conductivity of Ca²⁺ ions.

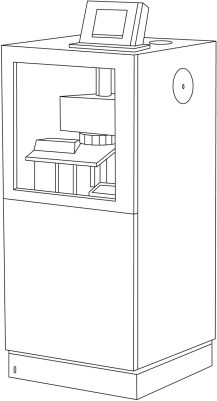

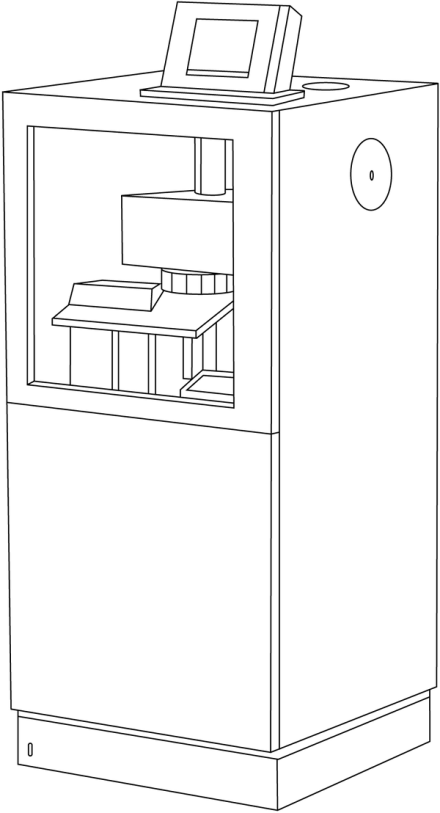

a standalone unit; an integrated unit in an automated laboratory; or a containerised process solution at a process line.

a dosing device; a balance system with an analytic temperature-stabilised head dedusting, cleaning and evacuation pump; heated reservoir of ethylene glycol

Reliable analysis of free lime for optimal cement quality and process stability

Accurate

Strong

User-friendly

Fast

Conventional methods of measuring free lime including x-ray fluorescence and x-ray diffraction have a host of limitations including measurement restrictions and under-detections which can cause skewed results. That’s why, if you want a high-level of accuracy, you can be assured our FLA100 Automatic Free Lime Analyser uses the most advanced instrumentation and controls to get the results you need by: Controlling the automatic analysis cycle Allowing manual or automatic sample loading Enabling local and remote diagnostics Including alarm and event reporting Analysing calibration and data presentation. The QCX FLA100 is supported of our global service organisation – giving you fast and easy remote troubleshooting and total peace of mind.