A gear unit that helps you reduce operational costs

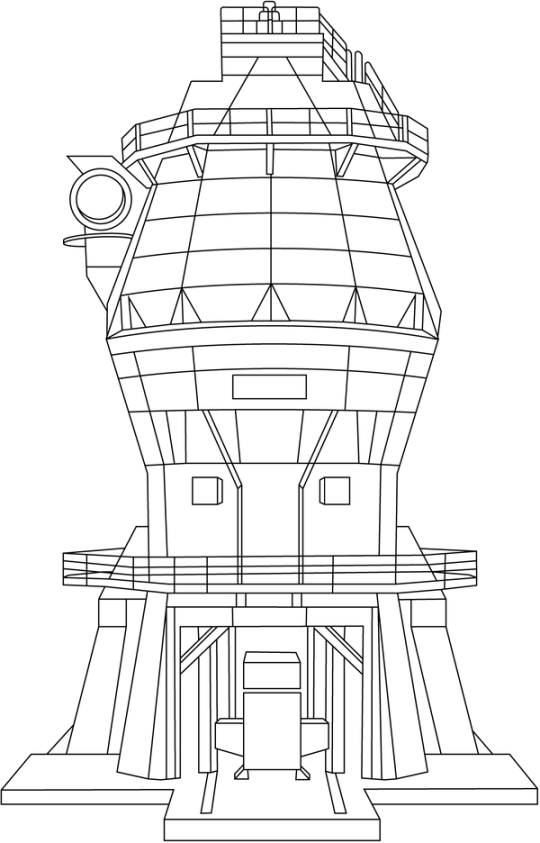

Cut operating costs. It is that simple. The new MAAG IronDrive Gear Unit is our most efficient drive for vertical roller mills of all sizes, enabling you to increase sustainability. Reliable and safe – it’s the ideal gearbox for all vertical roller mill applications, including coal grinding.

The most efficient gear unit for your vertical roller mill

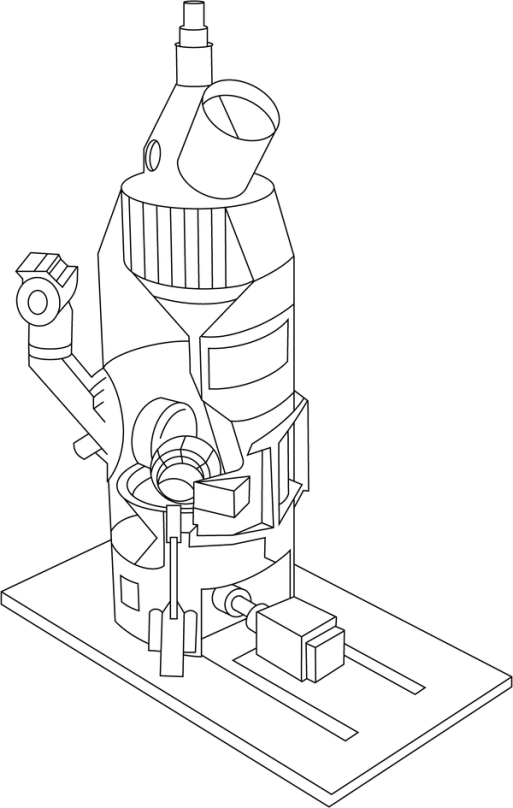

The power consumption of your vertical roller mill is a significant operational cost - with a hefty environmental impact With the new MAAG IronDrive Gear Unit, you have the opportunity to reduce your costs while still benefiting from the exceptional reliability of this bevel planetary gear unit. Suitable for a wide range of mills and arrangements, the series accommodates power ranges from less than 1000 up to 9000 kW.

Capable and flexible

The MAAG IronDrive combines proven technology with the necessary adjustments to deliver high functionality for vertical roller mills in cement plants and other industrial segments. The standardised design of the IronDrive gear unit allows you to use the drive unit in all types of mills and plant arrangements.

Smart maintenance, high performance

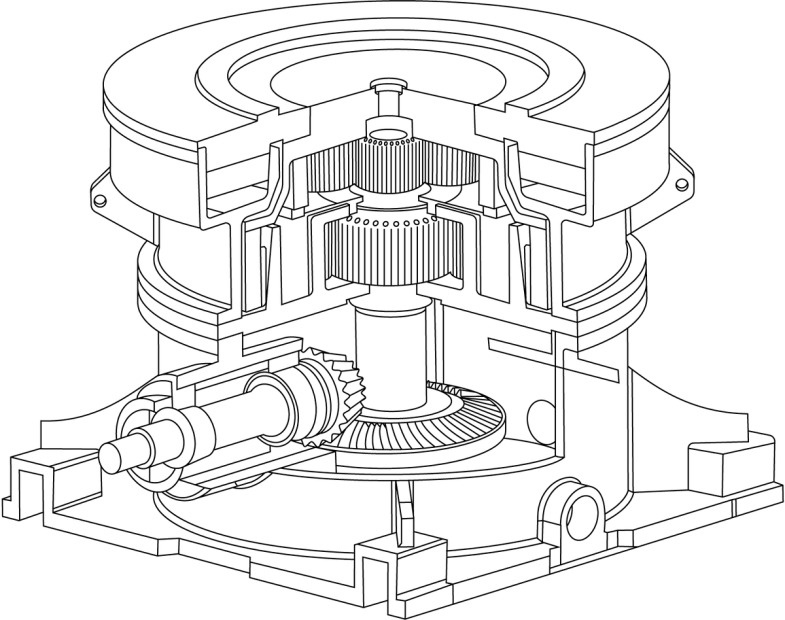

The MAAG IronDrive has the most maintenance friendly design compared to its predecessors. We put a strong focus on operational safety with smart design features like:

Safety shoulder to protect the planetary stage from excessive table wobbling,

Good accessibility to the bevel stage for inspections or periodical maintenance without having to remove the gear unit from below the mill.

The MAAG lubrication concept with an external oil tank allows access to the bevel stage at any time without having to first drain the lube oil into separate oil containers

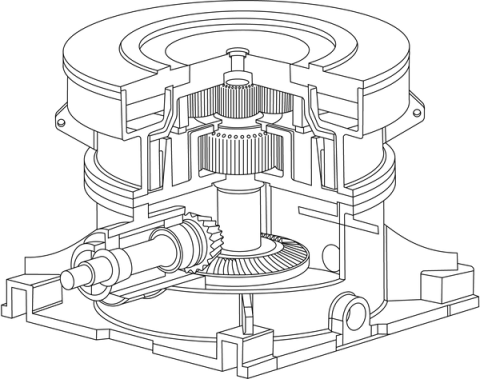

Torque transmission that fits your mill

The MAAG IronDrive fits perfectly in the classic vertical roller mill drive arrangement, where a horizontally oriented electrical motor provides the drive power and rotary motion. The first reduction stage in the gear unit, the bevel stage, redirects the horizontal rotation into the vertical axes of the mill and is followed by a planetary gear stage, according to your torque and ratio requirements.

The ring gear of the planetary stage is used directly as part of the casing in the larger series of our MAAG gear units. This design feature enables us to apply the bigger ratio in the planetary stage and consequently to minimize the ratio in the bevel gear stage. In this way, we can increase the transmittable torque of the MAAG IronDrive to the maximum.

Beyond a basic condition monitoring system

All of our gear units are equipped with unparalleled condition monitoring sensors. Normally, these types of sensors keep an eye on critical operating parameters like bearing temperatures, casing vibrations, etc. and trigger a mill shutdown in the case of exceedances.

Our Predicta online condition monitoring services do so much more. Now you can set up condition-based preventive maintenance that uses continuous monitoring and data analysis to detect wear and tear at an early stage. With this enhanced information and mySentinel Service Agreements we help you plan maintenance and servicing in advance – reducing downtime and keeping your plant running smoothly.