Heading in the right direction: Diverter Valves from FLSmidth

SK™ V2 pneumatic conveying diverter valves for efficient and reliable control

Sometimes A to B is as simple as a straight line. But when it’s not, you need a diverter valve that ensures seamless redirection of materials with minimal wear and maximum efficiency.

Accurate, efficient and flexible

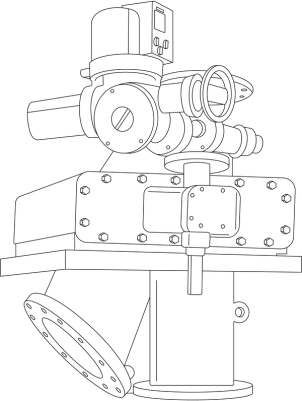

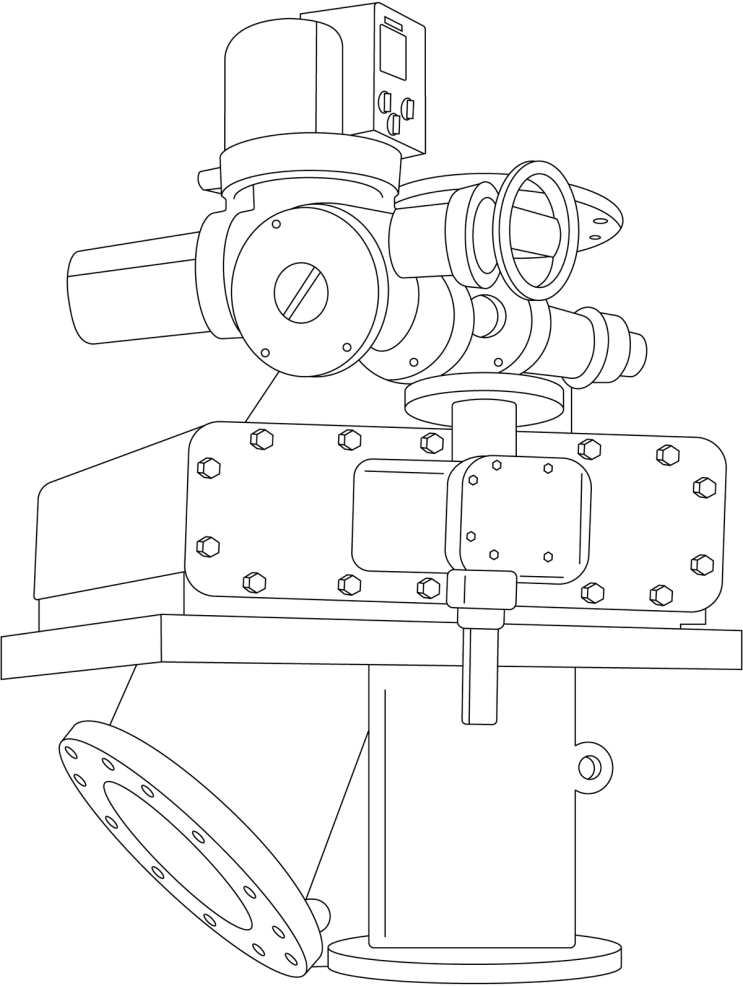

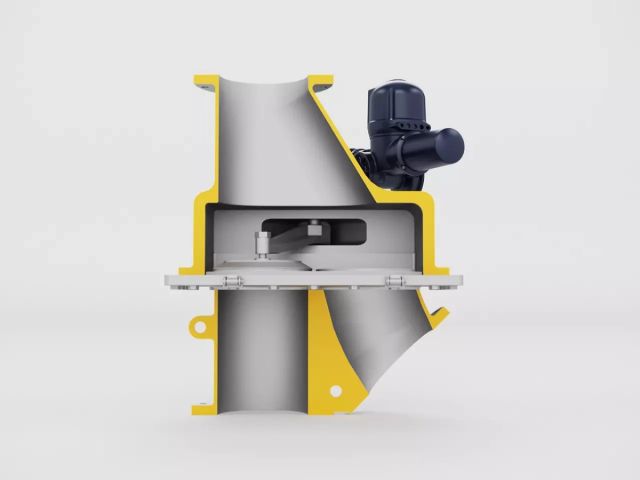

Our Two-Way Diverter Valves have a straight passage and a branch pipe mounted at an angle of 25°. One of the two outlets is always completely closed by a tightly-sealed slide plate. The slide plate is activated by a shaft and a lever and moves on an exchangeable wear protection plate. Switch-over is possible only when conveying operations have been stopped. Your network of conveying pipes can take all forms, so we’ve ensured our Two-Way Diverter Valves are flexible to your application. They can be installed horizontally or vertically. The branch pipe can be mounted on the right or left, depending on the pipeline routing. And they are available for all commonly used nominal widths, so they can be installed in almost all pipeline systems.

Smooth bulk material handling for easy conveying in any direction

The SK V2 diverter valve has a new leaner profile with streamlined parts and lower weight. The seat cartridge is all one piece and it’s easily replaceable via the over-sized hinged access port. The SK V2 is designed for both diverter and converger duty and is available in either standard or ATEX 20 versions. It can be positioned in either right or left hand configuration and re-purposed on site. Actuation is manual, pneumatic or mechanical and no linkages or guards are required, so it’s safer to operate. Control and indication are situated in the actuator. Engineered for 50 psig and 200˚C maximum temperature, this rugged valve is well-suited for various abrasive materials such as cement, limestone, bentonite, fly ash, copper concentrate, barite and other pulverized or granular materials. The SK V2 valve is compatible with dilute-, two-phase or dense-phase pneumatic conveying applications.