Driven by

an extraordinary

passion

Scroll down

and explore the timeline

Scroll down

and explore the timeline

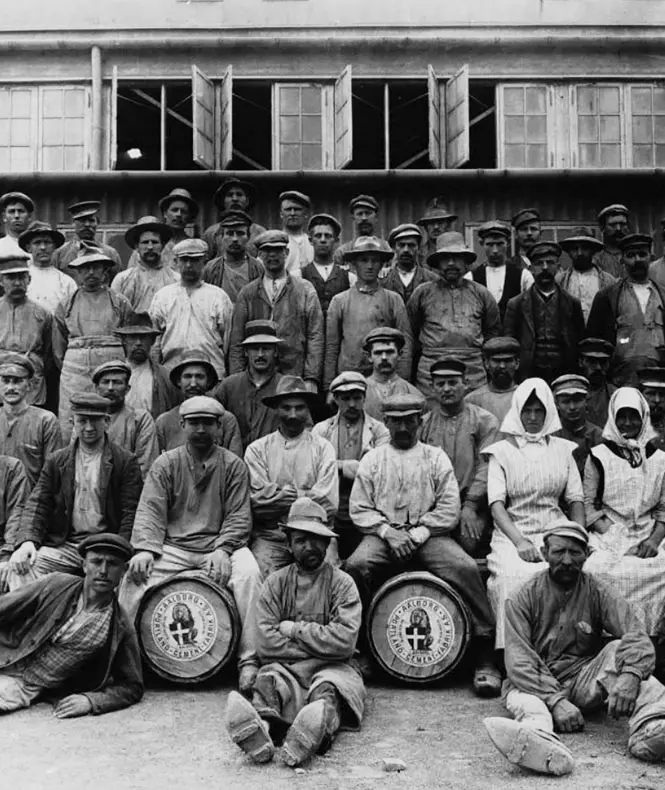

As a global company especially affected by the world wars and challenges in maintaining normal operations, FLSmidth develops solutions for other industries, which helps to retain employees and maintain the spirit of innovation.

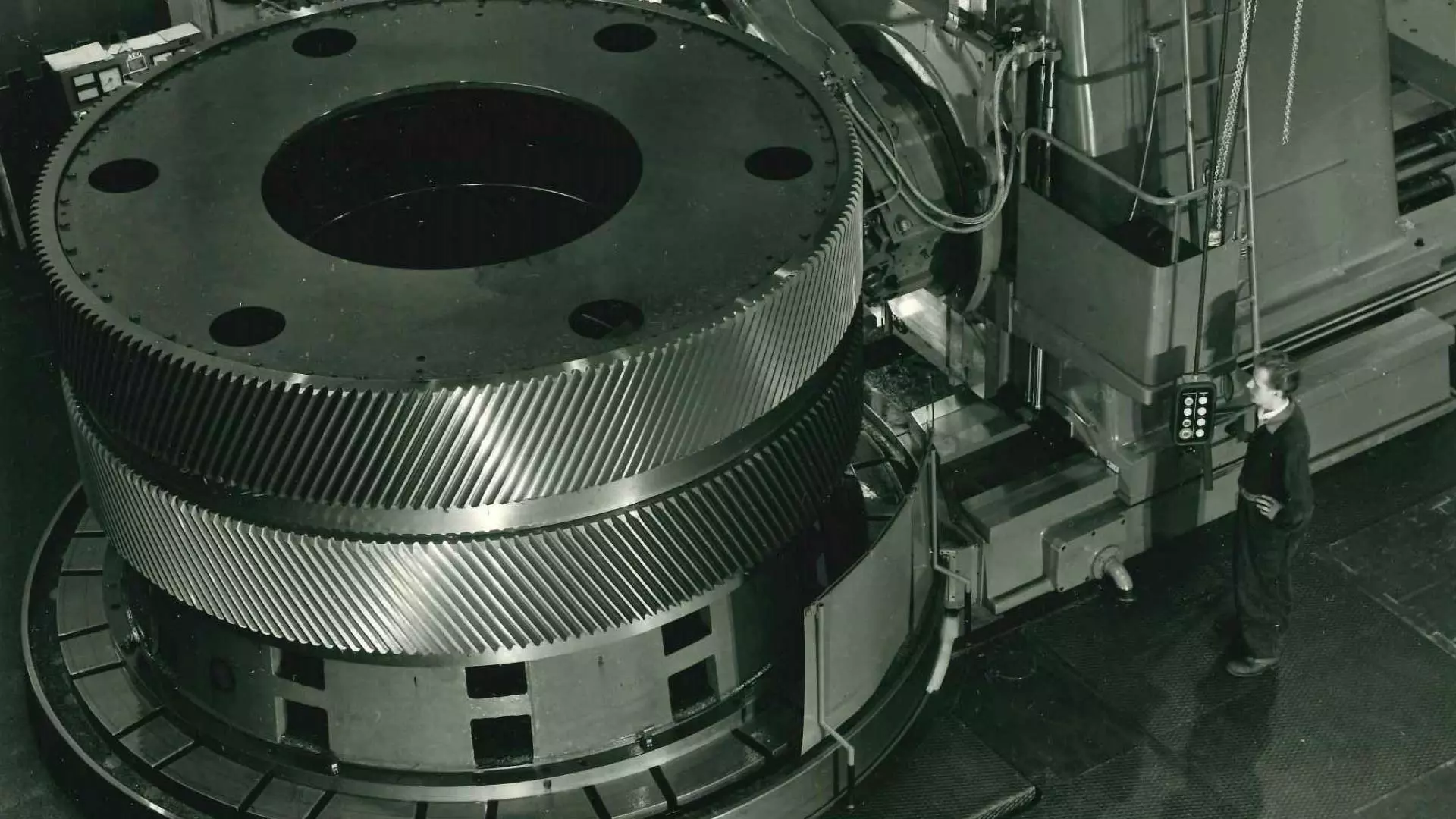

FLSmidth invents the SYMETRO™ gear, which replaces mechanical features with various motors that can operate huge machinery. The Symetro gear has proven itself with unprecedented durability, with some still in use to this day.

1926

The first SYMETRO™ Gear Unit is installed.

MADE TO LAST

SYMETRO™ Gear Units are still manufactured today, delivering high efficiency, durability and easy maintenance.

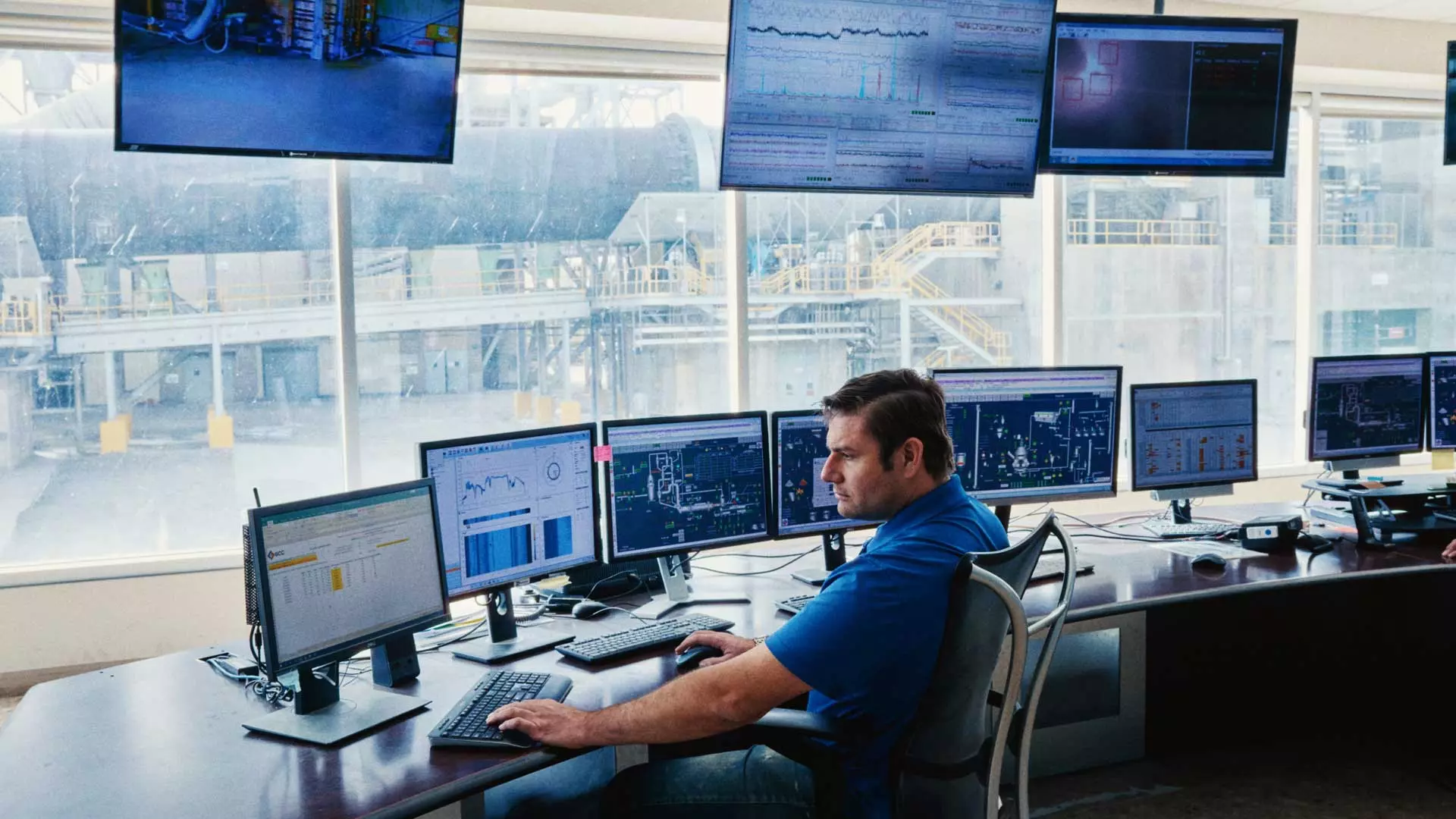

Our digital solutions and innovations in data-driven optimisation are enabling customers to meet their sustainability and productivity goals.

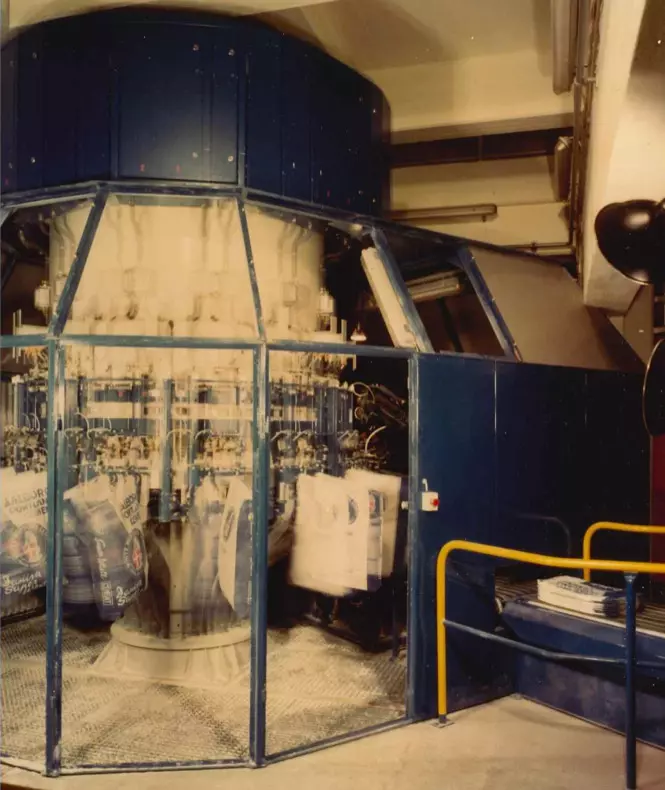

Early automation innovations in the 1960s transformed raw material blending and quality analysis.

Today, digitalisation is at the heart of sustainable productivity in mining and cement.

We are on track to help move the mining and cement industries forward, drastically reducing emissions and the environmental impact of operations.