-

Get more from your equipment with EXCEL™ Premium Replacement Parts

Did you know that you can get replacement parts for your cone crusher, gyratory crusher, hydraulic excavator, electric shovel, dragline, and mill from us?

Re-engineered Parts

Original equipment manufacturers often leave room for improvement when it comes to part performance and site-specific considerations on the machines they design. EXCEL™ replacement parts are designed to get you: better performance, longer wear life, improved safety, higher quality, fully OEM compatible, yet re-designed and more durability. The only things you will see less of are maintenance and expense. We have been developing and manufacturing replacement components for more than 80 years, and we have produced a wide line of parts that surpass what you can expect from the equipment manufacturer.

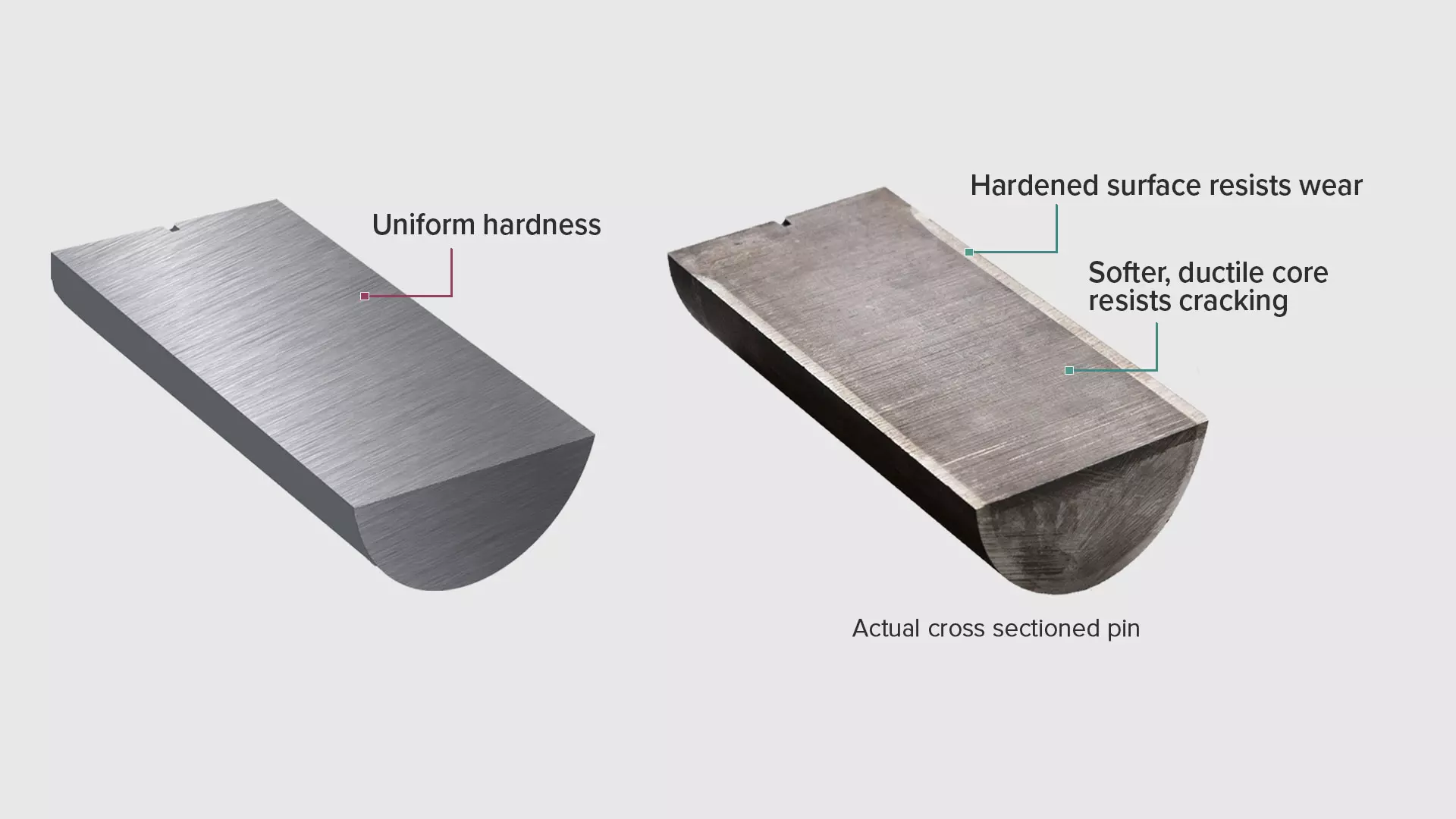

Pin Production - Science for better performance

Our hardened pins have an extended service life because our unique hardening processes penetrate the pin deeper than our competitor’s pins, without sacrificing toughness. Conventional OEM pins have approximately 12.7 mm (1/2 in) thick hardened layer. Ours consistently have a hardened layer that is 17% deeper with a layer that is 14.9 mm (19/32 in) thick. For extreme applications where maximum wear life is mission-critical, we also offer our chromium-carbide weld overlay pins at a hardened depth of all the way up to 19 mm (3/4 in) thick.

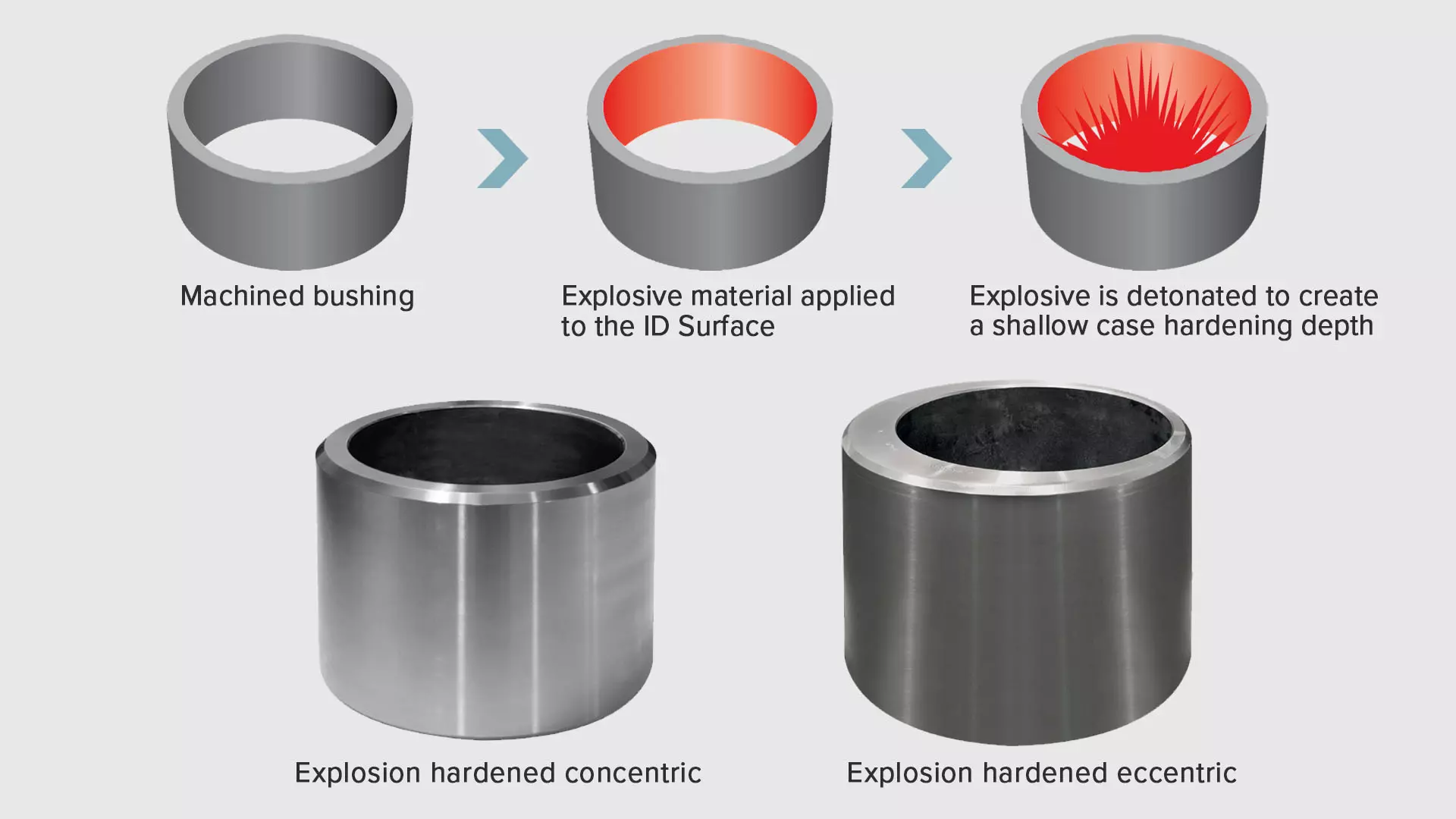

Work-hardened on day one

Explosion hardening technology for Manganese Steel

- Meant for extreme, abrasive applications

- Reduces “wear-in” time and metal flow during initial work hardening

- Pre-hardened in a unique impact process

- Increases hardness by upwards of 75 BHN

- Increases wear life by reducing material loss during break-in

Durability and longer life

Maintenance is expensive, and you need parts that are more durable and last longer. We are proud to provide replacement components that outlast the original parts. Whether you need an assembly or a simple part like a bushing, we have earned our reputation for durability.

One of our customers in Alberta, Canada got five times the normal wear life when they switched from a forged bushing to our explosion hardened bushing. Another customer in Texas, US found that our extreme manganese steel bushing lasted 30% longer than the forged bushing they were using.

By studying the known failure modes of OEM components, we can attack and eliminate them through design innovation and manufacturing excellence.

Improved bowl threads

- Improved thread-start geometry

- Tapered thread reduces risk of galling and binding when threads engage

- Prevents possible cracking of adjustment ring and thread failure

- Two-part lubrication prevents galling during bowl movement

Service that makes a difference

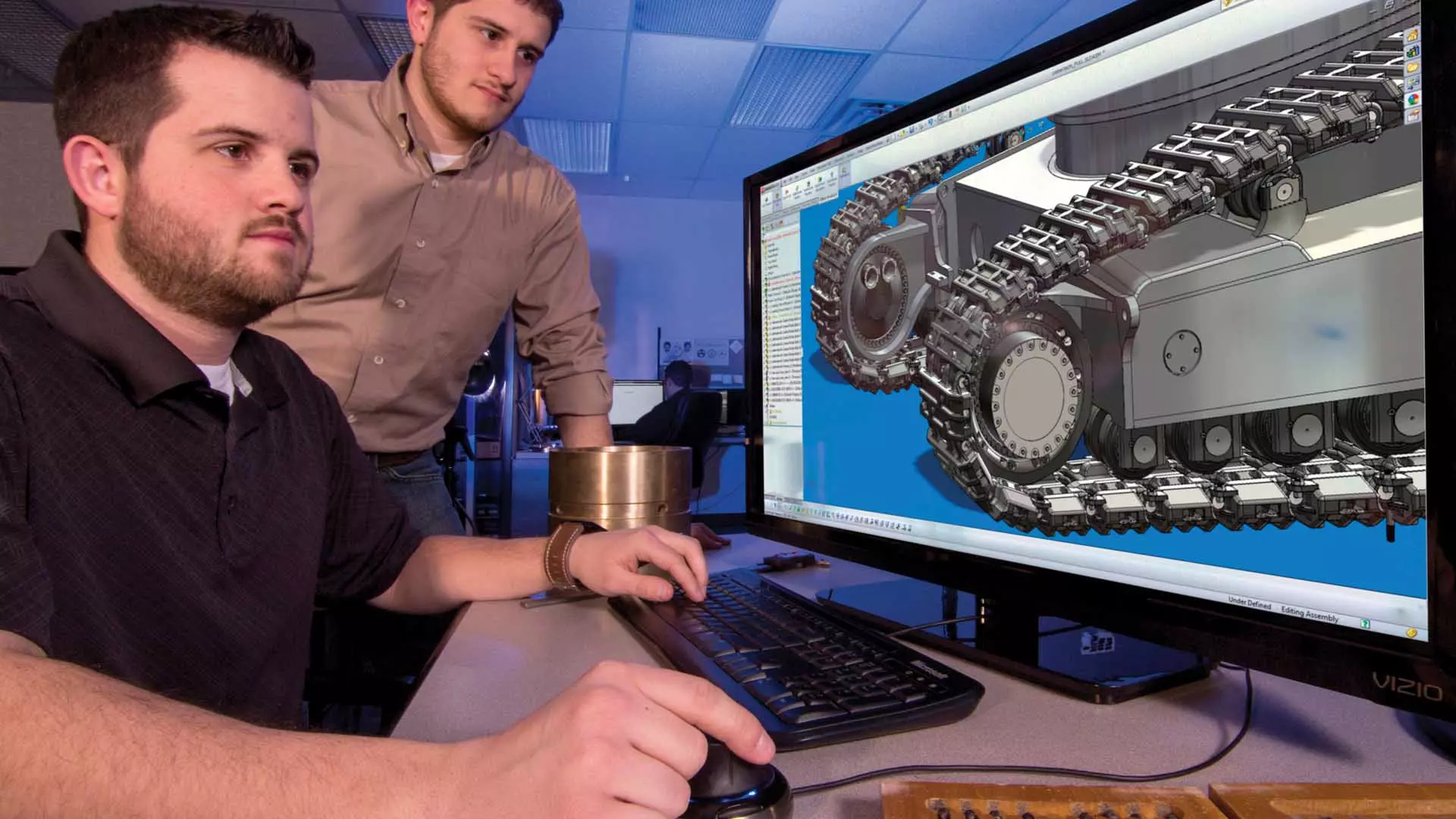

Our product is backed by a talented and accessible team of design engineers, technical service engineers, and metallurgical engineering expertise ready to offer support and add value when things don’t seem black-and-white. Yes, we’ve got state-of-the-art 3D-based design technologies in house, but we’ve also have experienced former miners and quarry engineers on staff to ensure that our design and support offerings are relevant in the real world. Whether it’s assistance with a part number application, a custom engineering / manufacturing request, a metallurgical analysis, etc. we’ve have a team you can count on for world-class service before, during, and after the sale.

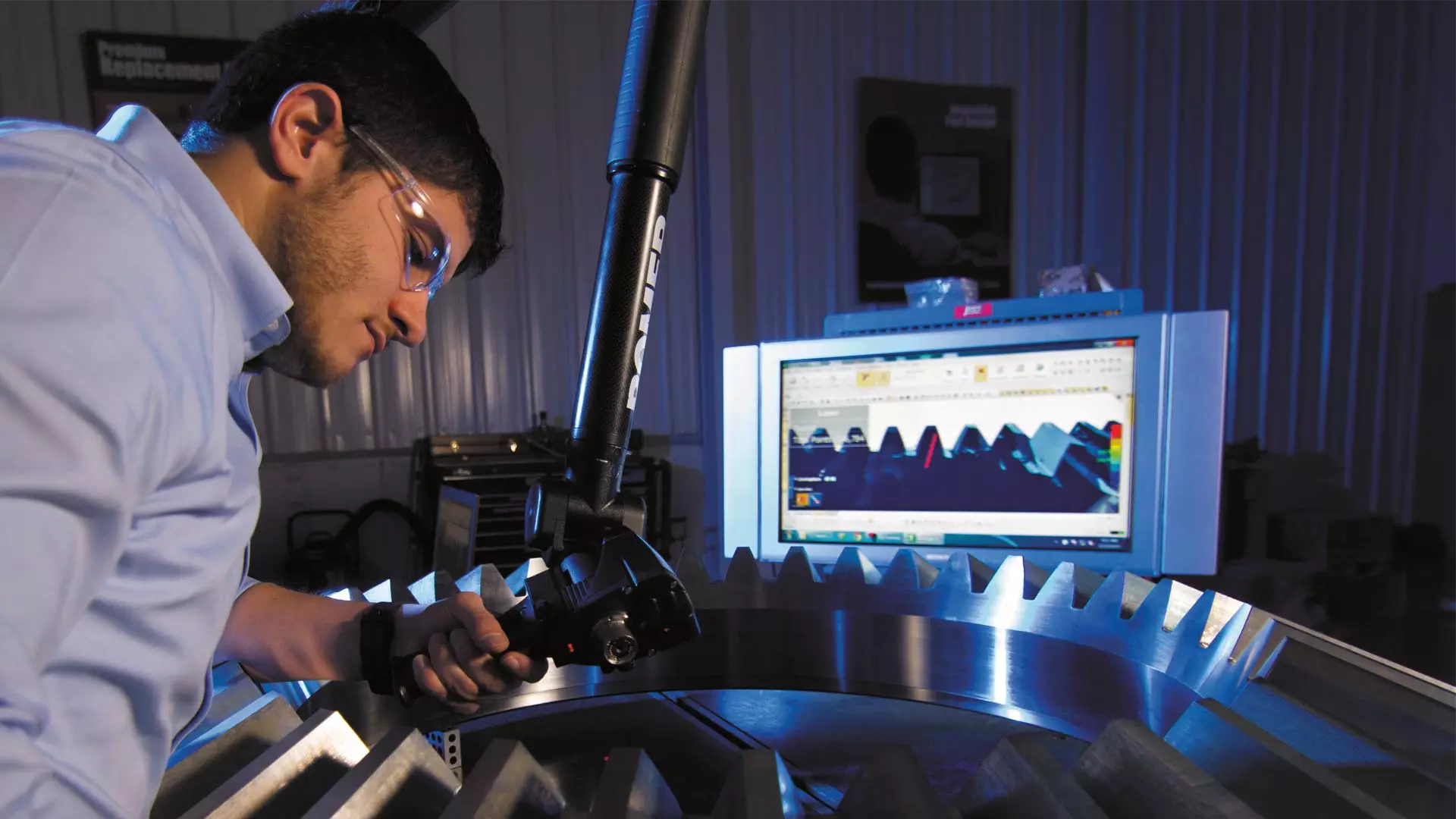

Quality assurance

In addition to only using premium materials, our strict manufacturing and foundry standards allow us to create parts that meet tight tolerances. Every part is inspected and certified to exactly match the specifications of the job. A large percentage of our production staff is solely dedicated to quality assurance inspections. We dedicate more time and people to our final inspections than any of our competitors.

We are ISO9001 certified, and our program is managed here along with our traceability and record retention. Our quality assurance protocols and procedures allow us to trace any part that we produce, even years later. For each part, we can confirm any possible production details that are needed.

We offer components for crushers and extraction equipment

| Cone Crushers | Gyratory Crushers | Hydraulic Excavators |

| Allis-Chalmers® Hydrocone | Allis-Chalmers® | Demag® |

| GP Series® | Nordberg® | Hitachi® |

| HP® | Metso® | Komatsu® |

| Metso® | Sandvik® | Liebherr® |

| MP® | ||

| Nordberg® | ||

| Omnicone® | ||

| Sandvik® Hydrocone | Draglines | Electric Shovels |

| Sandvik® Superior | Bucyrus® | Bucyrus® |

| Svedala® Hydrocone | Marion® | P&H® |

| Symons® Gyradisc® | P&H® | |

| Telsmidth® |

Talk to our North America Spare Parts Expert

-

EXCEL™ Cone and Gyratory Replacement wear parts

-

EXCEL™ High Performance Parts for your mining equipment

-

EXCEL™ Wide Path™ for P&H Electric Rope Shovels