Evaluate the technical performance of your laboratory with a lab audit

An opportunity to test your laboratory performance

Data is the driver that allows you to ascertain and improve product quality, process efficiency and environmental performance. You use that to make decisions about how you might adjust the process for optimum results. But if the data you’re using is unreliable, how can you trust the results? You can’t. If the data is bad, the results might be worse. An imprecise or inaccurate reading of the Lime Saturation Factor (LSF), for example, might mean problems controlling your pyro process and a lower quality product. Poor quality could cost you customers – or worse. Is that a risk you are willing to take? A lab audit will identify any weak spots in your laboratory operations, enabling you to tighten up practices and recalibrate equipment to get plant performance back on track.

0st

0nd

0rd

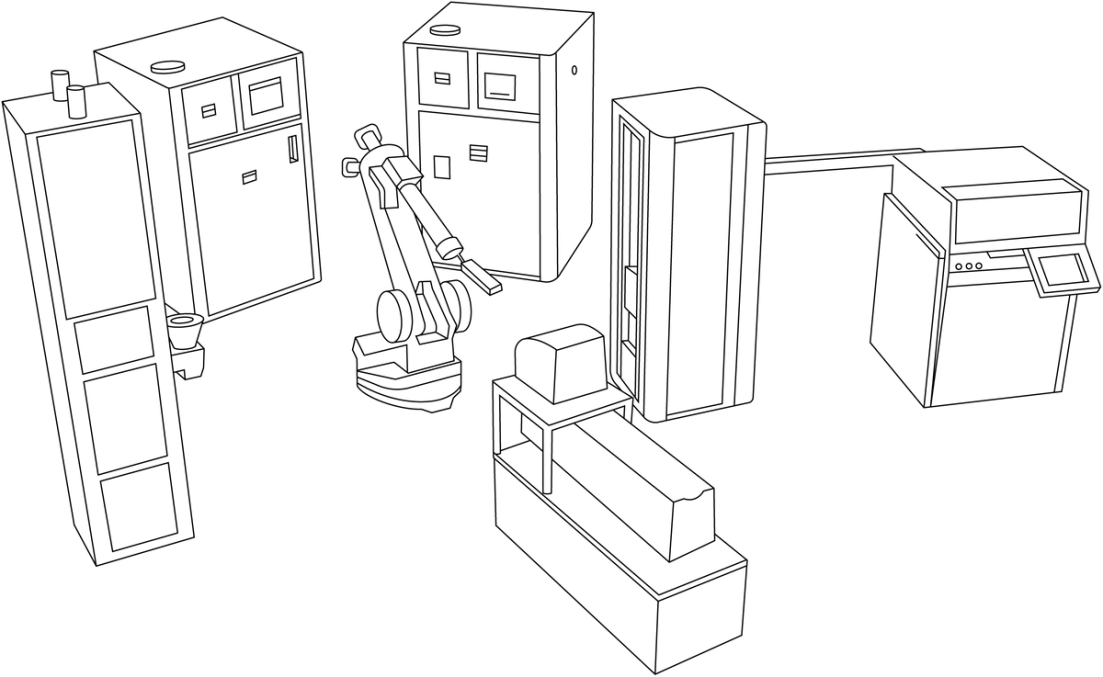

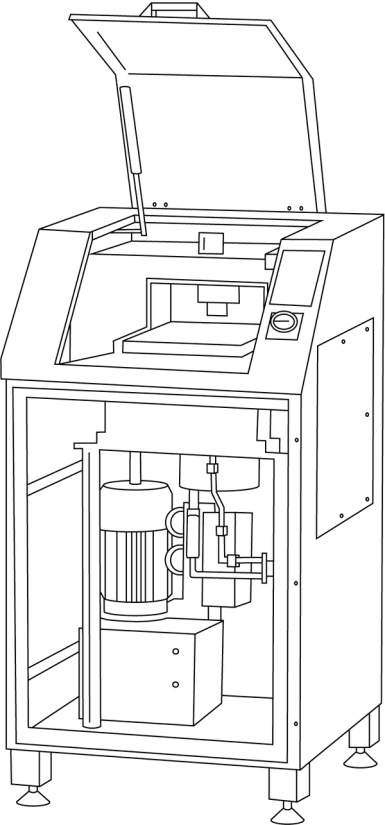

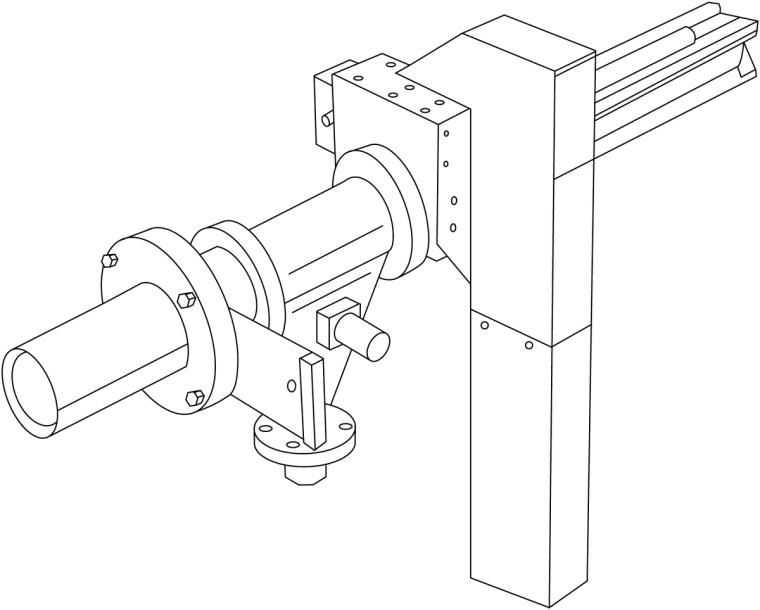

Your audit will be tailored to your plant, your lab setup and any particular concerns you may have. Typically, this will include an audit of all the main laboratory analyses: XRF, Alkali, Sulphur, Free lime, Chloride, Fuel analyses, Sieving residues, Specific Surface area (Blaine), Cement strength development, Cement setting time More general areas, such as sampling frequency and procedures, sample preparation and quality control can also be included on request. Before we come to your site, we’ll ask for a defined set of material samples from across the process to be split, with one half sent to us for testing at our state-of-the-art laboratory and the other half tested in the plant. We will then include a comparison of the results in your audit report, which will help identify any areas that may be a cause for concern. On completion of the audit, you will be given a comprehensive report of our findings, including recommendations where improvements could be made, such as adjusting calibration curves for the XRF.

Why choose FLSmidth to audit your lab?

We don’t just know laboratory equipment – we know the whole process. Our comprehensive process knowhow enables us to look at the plant holistically and make connections that others simply wouldn’t see. It’s a niche position – and one we’re happy to hold.