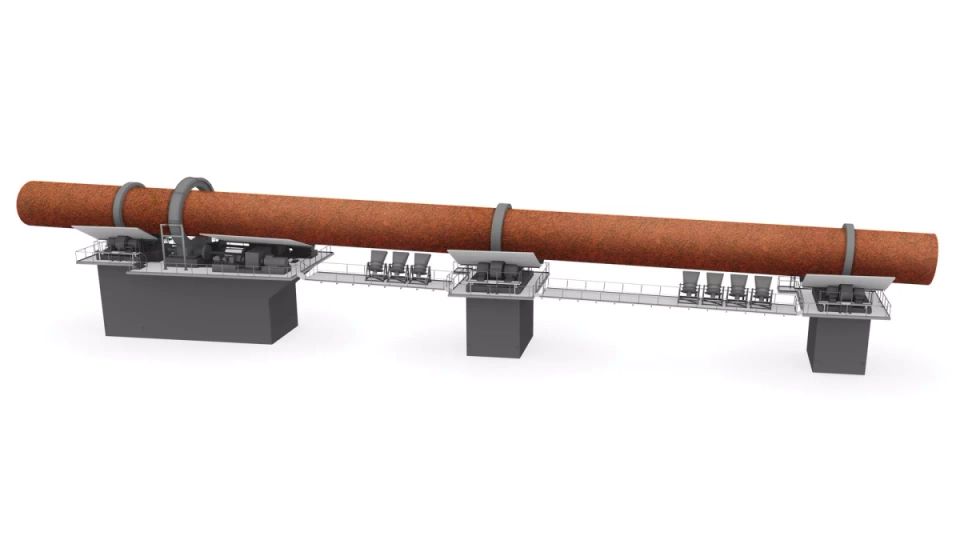

Prolong the lifespan of your kiln

A comprehensive kiln health check includes alignment and reconditioning

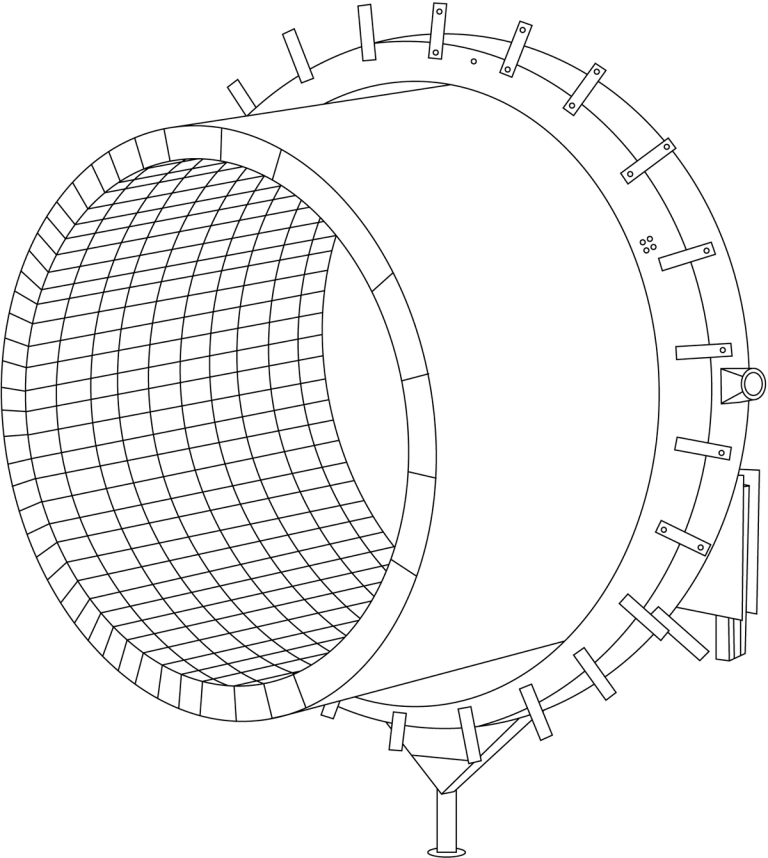

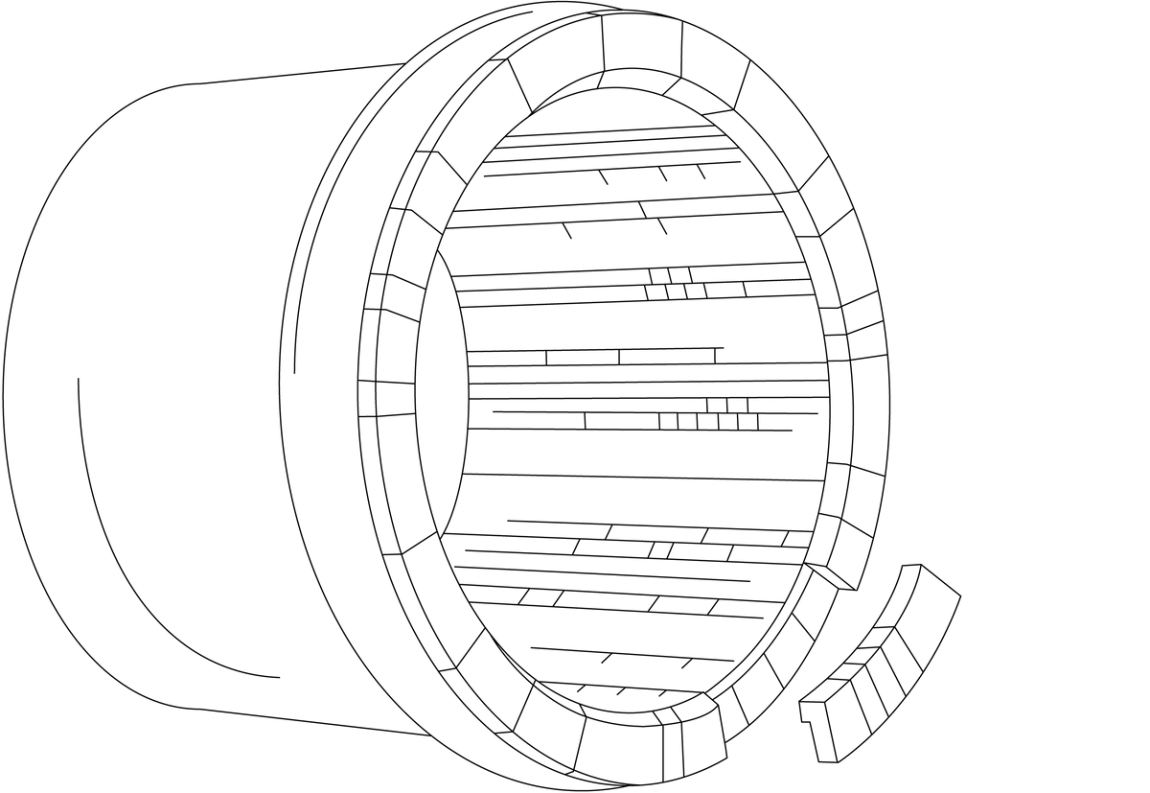

Achieving high kiln availability is essential to the competitiveness and profitability of your entire plant. You need to identify the root causes of kiln failure and eliminate problems before a breakdown occurs. Kiln services and maintenance help you avoid: Hot bearings, Kiln cracks, Wear on rollers and tyres, Wear between kiln shell and tyres, Lining failure

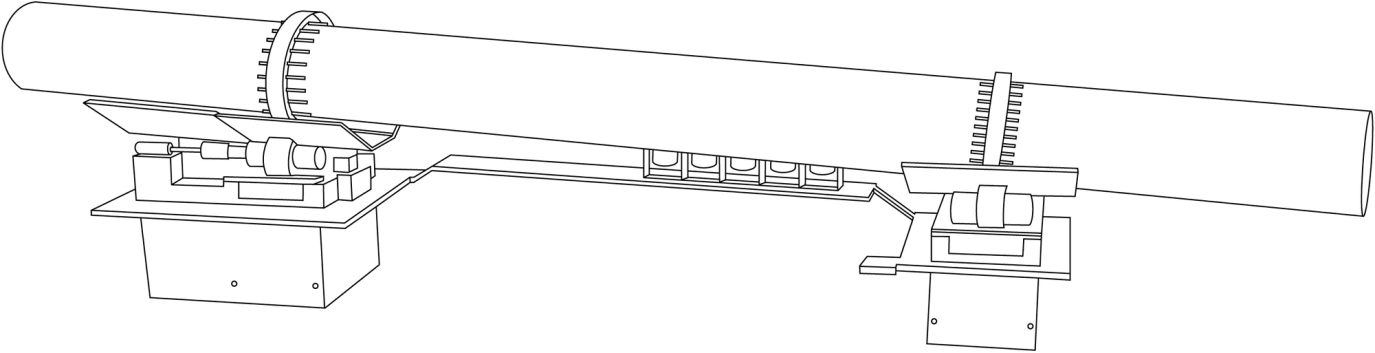

Our kiln installation services include:

- Delivery and replacement of field sections/tyre sections and rollers

- Delivery and installation of girth gear, pinion and drives

- Maintenance services on the kiln inlet and outlet sections and seals

- Change, reversal and alignment of girth gear, pinion and drives

- Installation of new kiln lines

We supply all the kiln installation tools required, including:

- Constructing support towers

- Cutting and welding equipment

- Lifting devices

- Auxiliary drives for kiln rotation

Match your needs for a skilled workforce

For you to enjoy the best results and peace of mind, we offer turnkey services that cover all your needs. Turnkey services are a combination of technical advisory support, skilled craft labour and state-of-the-art tools to execute work at the highest standards. We can provide this type of service for a variety of jobs from installations and adjustments to repairs, part replacements or rebuilds. Our level of involvement is up to you – so you can choose what works best for your business.