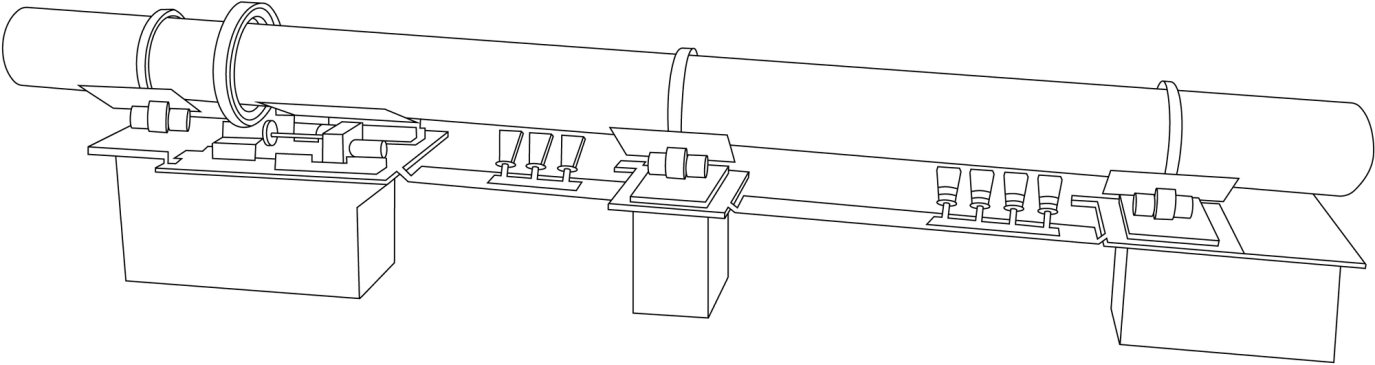

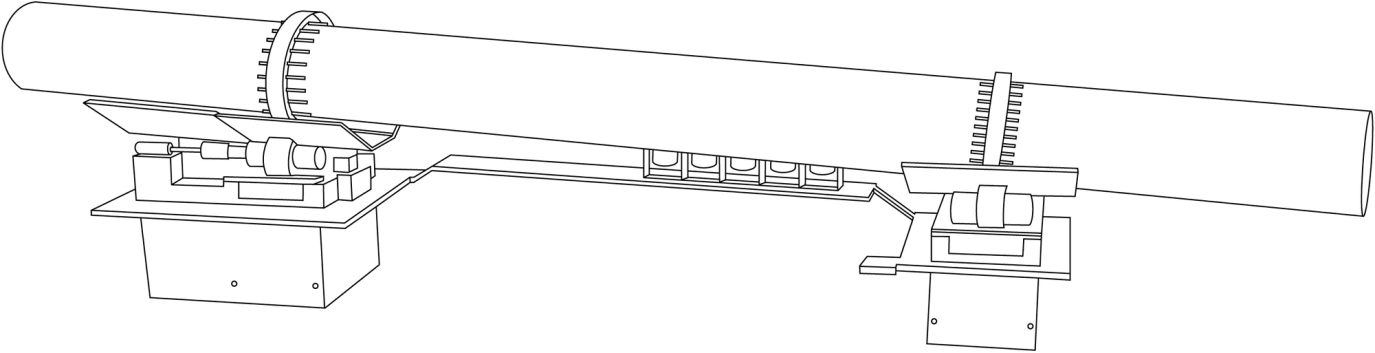

Hot kiln alignment: a pillar of your preventive maintenance strategy

Comprehensive kiln analysis with hot kiln alignment services

To keep your kiln operating at maximum efficiency throughout its entire service life, you need in-depth, accurate knowledge about its condition. A hot kiln alignment helps identify potential causes of failure before problems occur, giving you the information you need to avoid any unforeseen breakdowns. The better your maintenance programme, the greater your kiln availability. A comprehensive hot kiln alignment involves a visual mechanical inspection, including geometric and dynamic measurements. It also includes an engineering study, where we calculate stresses in the kiln and determine if there is overload, taking into account all the current operating conditions and the measured kiln axis. Everything is done during normal kiln operation, allowing you to continue production, uninterrupted.