Staying cool with preventative maintenance services

Maximise cooler availability and eliminate excessive wear

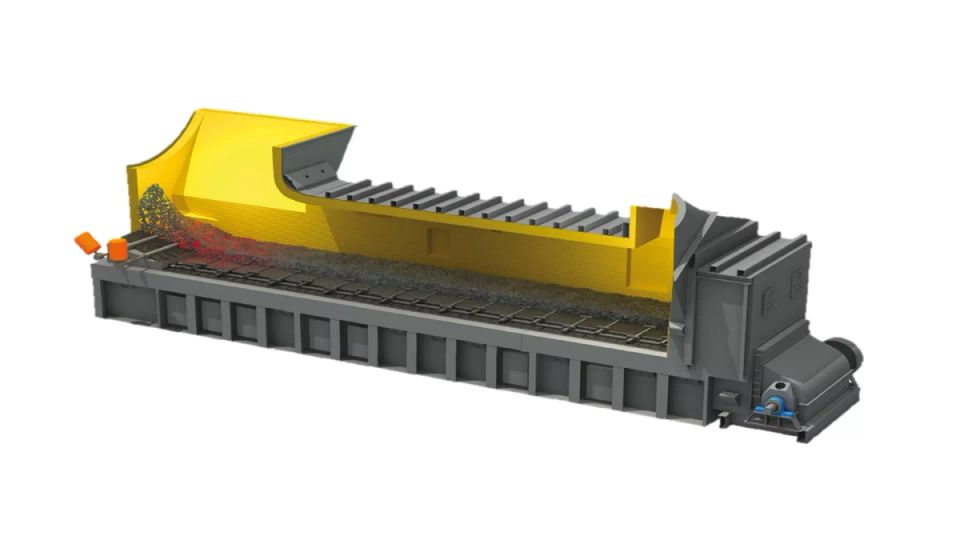

To maintain overall plant capacity, your cooler must handle a constant throughput of clinker. Problems with the cooler can result in an unstable kiln, damage equipment, and influence the clinker quality. And excessive wear of cooler parts can lead to inefficient cooling processes and even production stoppages. A regular preventative inspection can eliminate many of the root causes of excessive wear and keep your cooler running smoothly. As well as inspections, our on-site cooler services include: installation, repairs and refurbishments, and upgrades and overhauls.

A complete cooler analysis can help you reduce downtime and keep production levels high. A problem detected in one area can have its root cause in another. Using the latest fault-finding technologies, such as electronic data loggers and thermal cameras, we analyse each individual element in depth.