Est’d 1969: The automatic truck loader for cement from FLSmidth

An open top truck loader for optimal and efficient bag loading

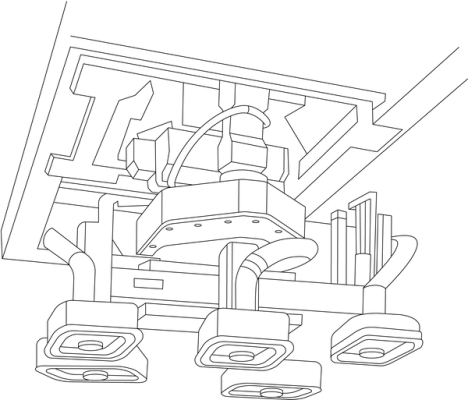

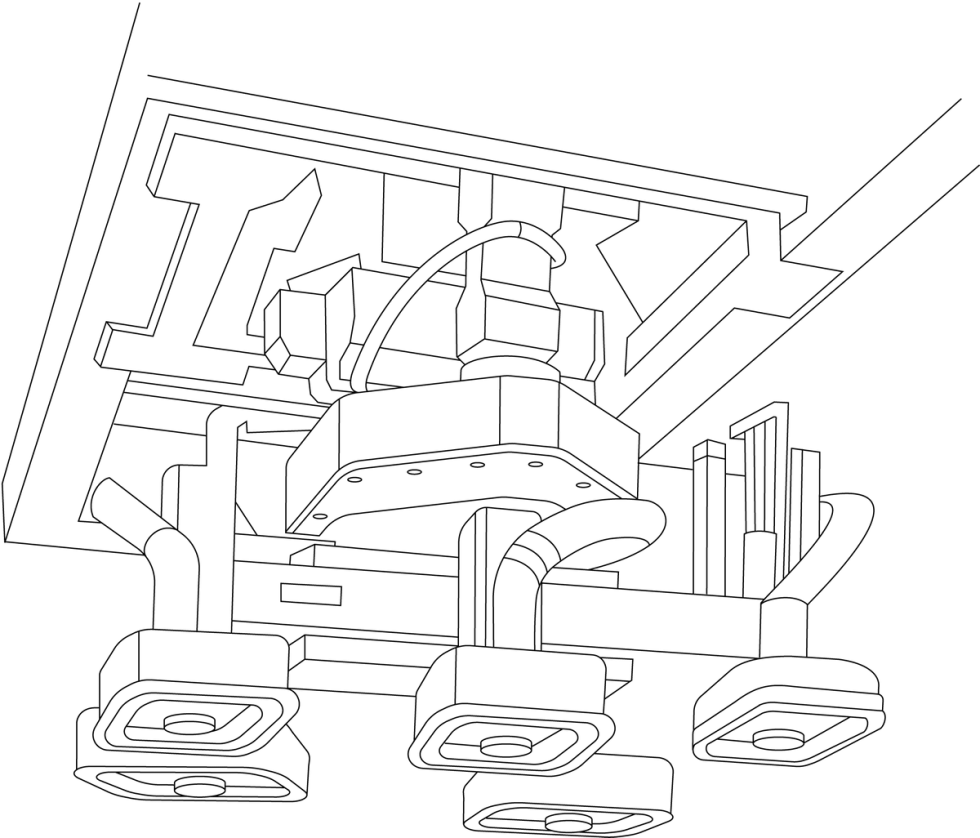

What impact does efficient bag loading have on your business? Smoother handling results in less product loss. Faster loading and truck changeover reduces bottlenecks and gets your product out quicker. Smart laying configurations enable you to achieve optimum truck loading safely, with low risk. All of these things enable greater productivity and profitability. We’ve been engineering bag loading technology since 1969. As the VENTOMATIC® CARICAMAT® has evolved, we’ve built in even more flexibility to ensure the broadest possible applications, whatever the truck type, bag size or environmental factors. The compact design of the equipment enables the smooth installation and commissioning of the automatic truck loader, whether it’s installed in new or existing facilities or to replace manual loading. The VENTOMATIC® CARICAMAT® palletises full bags directly onto truck platforms (with or without pallet). It’s compatible with a wide range of trucks, from flat type with fixed or removable side and rear panels, to dumper trucks and trucks with trailers.It’s highly reliable, even in the toughest conditions. The patented suction disc system allows the loading of all kinds of paper and plastic bags onto all types of open top trucks and trailers with standard configuration of 5x1, 5x2 or 6x2 bags per layer.The high capacity (over 3000 bags/hour) combined with easy and fast positioning of the equipment (useful when the truck is not aligned into the loading bay) guarantees you a high overall capacity of the packing line. Reduced manpower. Increased safety. No more bottlenecks. The loading head picks up the bag layers and places them onto the truck platform. The bag layers are interlocked to stabilise your stack.We use a suction cup to pick up the bags, which gives smooth handling without damaging the bag surface – or your product.

Smooth operator. Bag loading technology you can rely on.

Efficient loading of open top trucks

Less than 1 minute for truck changeover

The only truck loader with different solutions for bag feeding

The CARICAMAT® automatic truck loader can be equipped with one or two loading heads, depending on the number of bags per layer

NOTE: All layers are interlocked and pressed for optimal stability during transportation. Other configurations are available according to bag dimensions, layer configuration and truck characteristics