Simple but effective – accurate filling for big bags

A logical solution for bulk products logistics

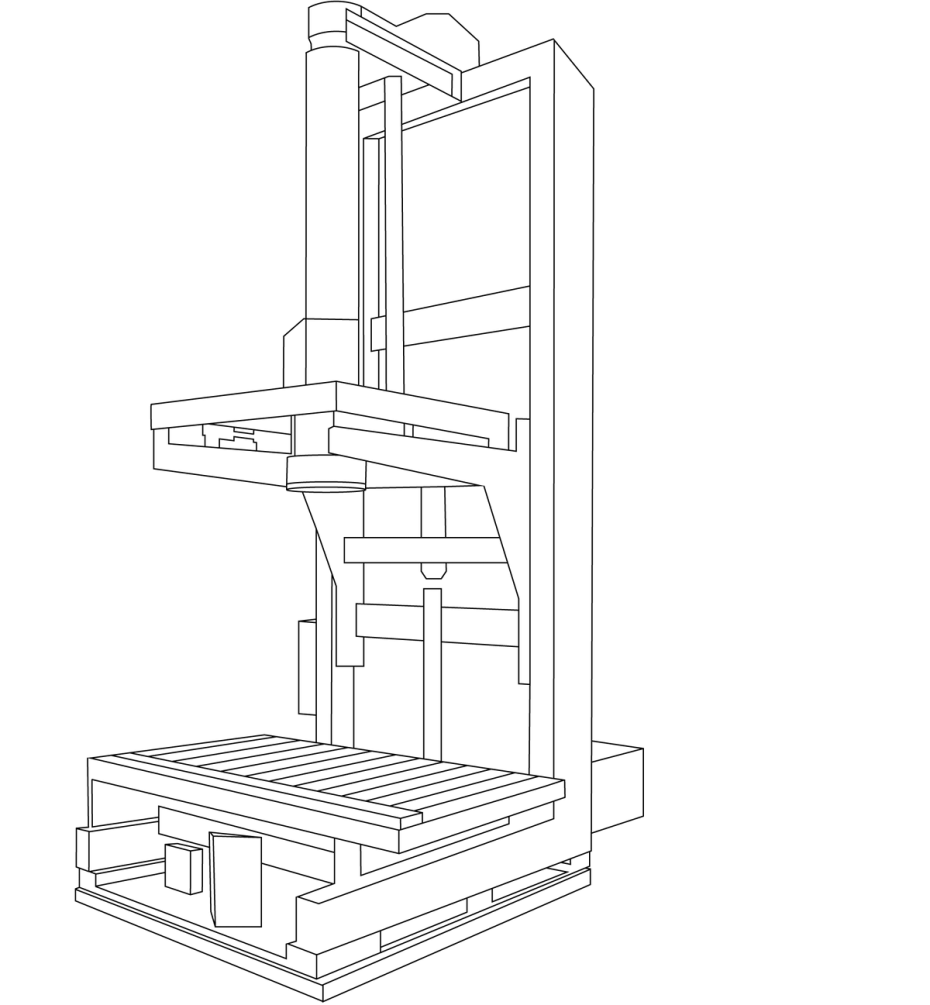

BIG BAGS offer cost advantages over small bags – but only if they’re being treated to the same degree of filling accuracy and efficient handling. Our VENTOMATIC semi-automatic big bags filling systems are capable of handling bags of different sizes, up to a total weight of 2 tons. These machines are simple to operate, flexible enough to cope with various powders and granulate products, and they deliver excellent weight accuracy. Electric weighing units placed beneath the supporting frame continuously monitor the big bag weight during the filling cycle, while a multi-position throttle valve ensures the utmost filling accuracy.

More accurate big bag filling

Automatic handling of the filled bags

Highly accurate weighing

Safe and clean working area

Suitable for a wide range of materials

Several features work together to deliver a clean, safe and accurate filling solution: A fan mounted onboard blows air into the empty big bag prior to the start of the filling cycle in order to inflate the bag. This ensures the optimum big bag geometry and uniform product distribution. The spout can tilt 30° towards the operator to make it easier to fit the valve into the spout. Once inserted, a rubber ring around the spout inflates to ensure an optimal connection, avoiding possible product spillage and dust emissions. A telescopic pipe connects the big bag to a dedusting filter. All these features are controlled through a user-friendly control panel placed next to the filling unit for easy operation. Four hooks hold the big bag in place. Before the loading cycle begins, the two at the rear move towards the operator to facilitate manual big bag loading, while during the unloading cycle all four hooks tilt by 90° to automatically release the big bag loops.