Reliable and trusted plant sampling and sample transport

A fully integrated automated system from process sampling point to laboratory

Our automated sample transport network links our reliable sampling equipment to our robotic laboratory cells. We have been actively involved in developing tube transport systems, which have been employed for fast sample transportation in harsh industrial environments, since the 1960s. Our market-leading position is solid within this technology through the execution of hundreds of projects with automated sampling and sample transportation to customers worldwide. The QCX/AutoSampling™ software is very user-friendly – the solution is highly flexible with well-designed user interfaces that provide an unmatched overview of the complete automated sampler-to-laboratory system.

Get the right sample to the laboratory faster and keep your quality under tight leash

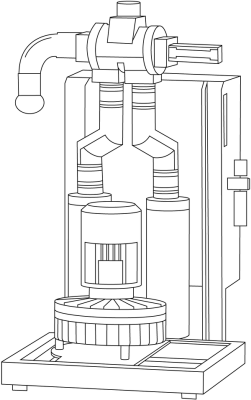

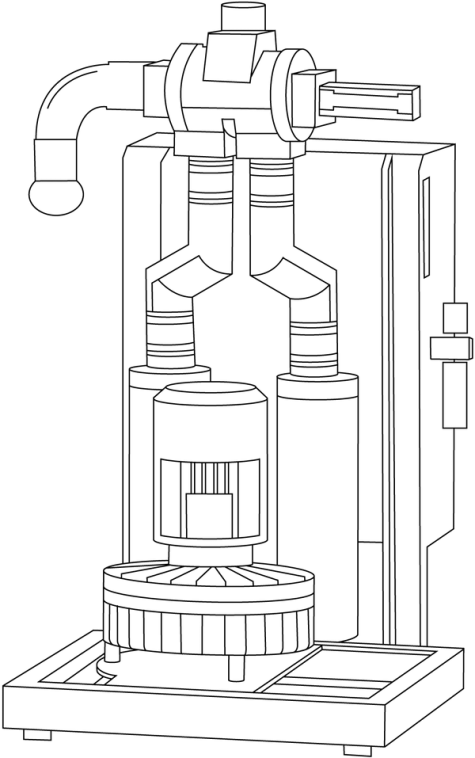

QCX® AutoSampling controls the sampling and pneumatic transport – via a tube transport system – of sampled material from the process areas to a central production laboratory or to designated “satellite” laboratories. Manual, semi-automatic or fully automated send/receive stations are available both at the process end and the laboratory end of a pneumatic sample transport system. Automated sampling equipment for powder, granulate and/or lumpy materials can be connected to the process send/receive stations, thereby ensuring fully automated systems. A typical project scope may comprise: Automated sampling equipment Process send/receive stations Laboratory send/receive stations Transport tube and tube diverters Transport air blowers Project-specific control hardware and software Optional sample ID entry terminals QCX/AutoSampling™ supervisory software Project engineering services Factory acceptance testing Installation supervision and commission services. Samples are transported in sample cartridges (or carriers or shuttles). For dry powder/granulates, typically 250 or 500 cc material is sent to the laboratory. Send/receive stations – in the process area or in the laboratory – may be manually serviced or fully automated, which, at the process end, means full automation of the entire sampling and sample transport process. The sampling and transport system is controlled from built-in control components undertaking the equipment device control and a central QCX/AutoSampling PC/PLC system which handles the coordinated traffic control, sample identification, sampling schedules, transport priorities, visualisation, alarms etc. You can be sure that our automated sample transport equipment and associated QCX/AutoSampling software system will result in quality optimisation through the complete sampling process in the cement plant. It can be seamlessly configured to suit your work processes, and most importantly, delivers reliable data.