It’s the clinker crusher your process deserves

When clinker boulders get stuck in your crusher, you have no option but to shut down the cooler while you clear the blockage. Costs go up, productivity goes down. It doesn’t have to be this way. The Heavy-duty Roll Breaker crushes through the biggest boulders with ease. No more blockages, no more lost productivity.

Crushing it, 24/7 with the Heavy-duty Roll Breaker

Every cooler will experience clinker boulders from kiln – it’s how you deal with them that counts. The Heavy-duty Roll Breaker can crush boulders up to 1.5 m with ease. No blockages. No downtime. Just high productivity, low maintenance clinker crushing.

Out with the old, in with the new

Traditionally, hammer crushers were the equipment of choice for clinker crushing operations. But hammer crushers are high impact, high wear, and highly prone to blockages. When the clinker boulders get stuck in the crusher, your only option is to shut down the cooler and the kiln while you clear it. We’re talking several days of lost production – and significant costs.

And even when they are working, the impact of the hammers sends bits of clinker flying around the cooler causing wear to equipment and refractories. Added to which, the hammers themselves need replacing on an annual basis. The costs just keep mounting up.

Low maintenance by design

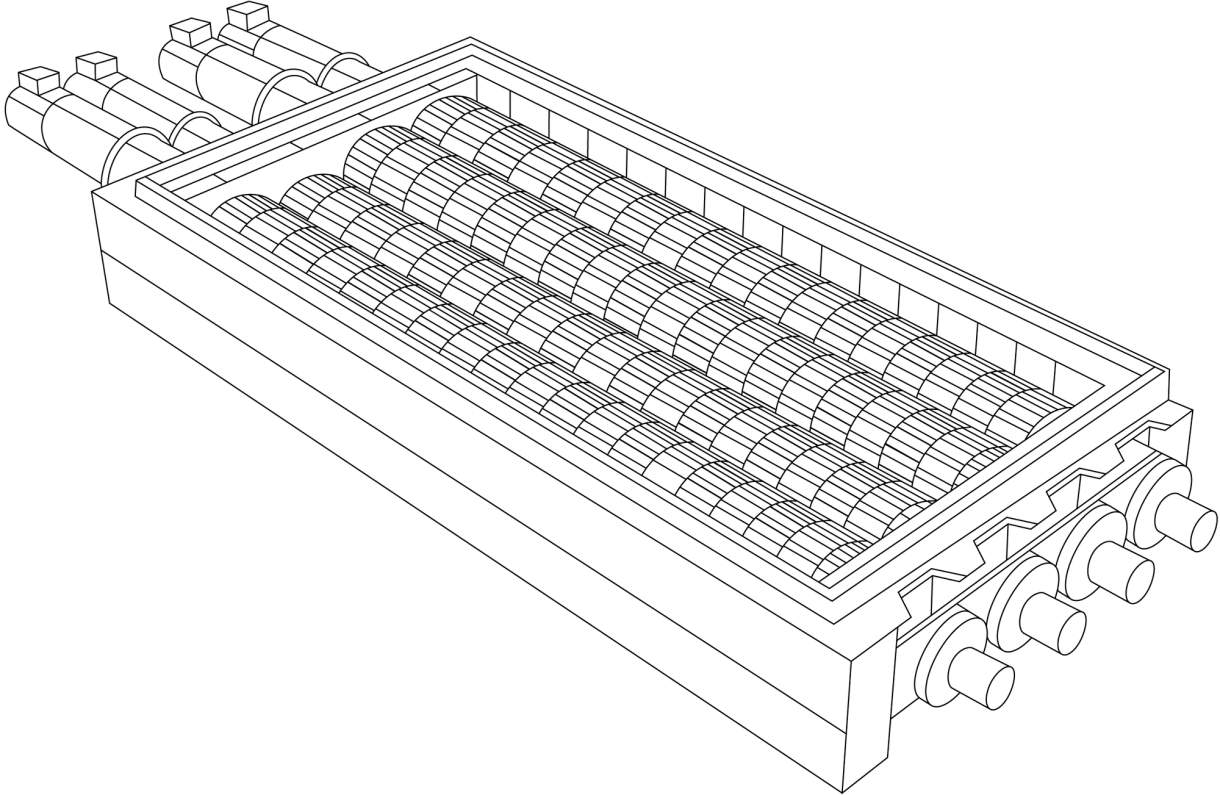

The Heavy-duty Roll Breaker is designed to operate at lower speed that does not have the same wear impact as a Hammer crusher. The crushing segments has a wear lifetime of at least 3 years and have been known to last more than 5 years, thereby a low maintenance.

Effective crushing of clinker boulders

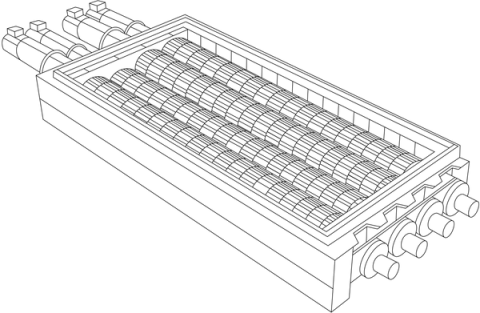

It’s called ‘Heavy-duty’ for a reason. The HRB has been known to crush boulders as large as 1.5 m without any problems, thanks to the clever design and arrangement of the transport and crushing rollers.

Very low maintenance

The HRB’s main wear part – the cast segments covering the roller – have a life expectancy of at least 3 years and have been known to last more than 5 years, depending on cooler capacity and clinker granulometry.

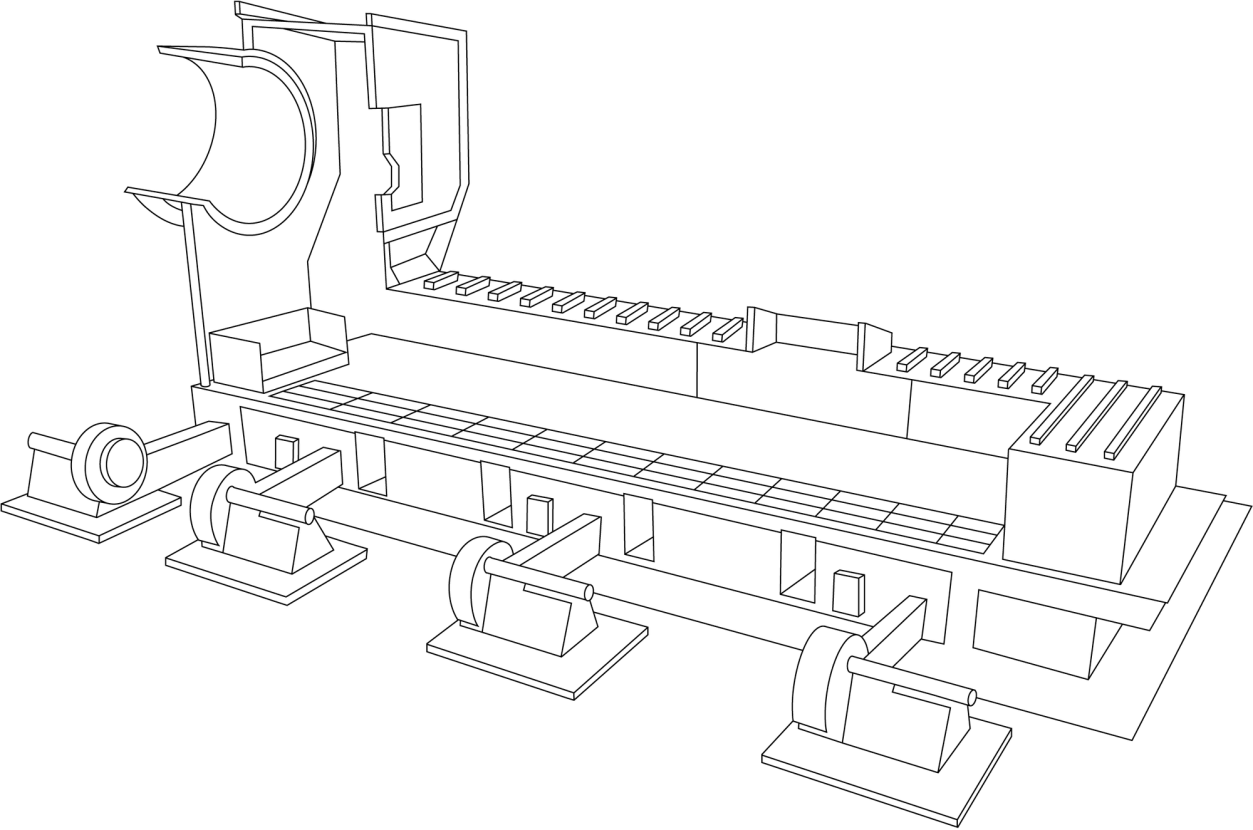

In addition, the HRB is designed for easy maintenance access with a special ‘roll out’ feature. You can choose whether to have the rollers roll out of the left side, right side or rear of the cooler (in a standard end-of-cooler arrangement) according to the space available at your site, making wear part changes quick and easy.

High availability and long wear life

A simple check-up during your annual maintenance outage and proper lubrication is all that is needed to keep this mighty machine in good working order. And with no blockages to slow you down, there is nothing to stop your clinker crusher keeping up with the rest of your pyro process.

Full control

The HRB’s control system continuously monitors the torque of the rollers. When torque exceeds a certain limit, the system knows that a blockage needs attention. The rollers will automatically stop, reverse, then start again. This process is repeated until the lump has been crushed to appropriate size. The control system is IOT-ready and can be connected to the internet for remote commissioning and assistance if required.

Flexible layout

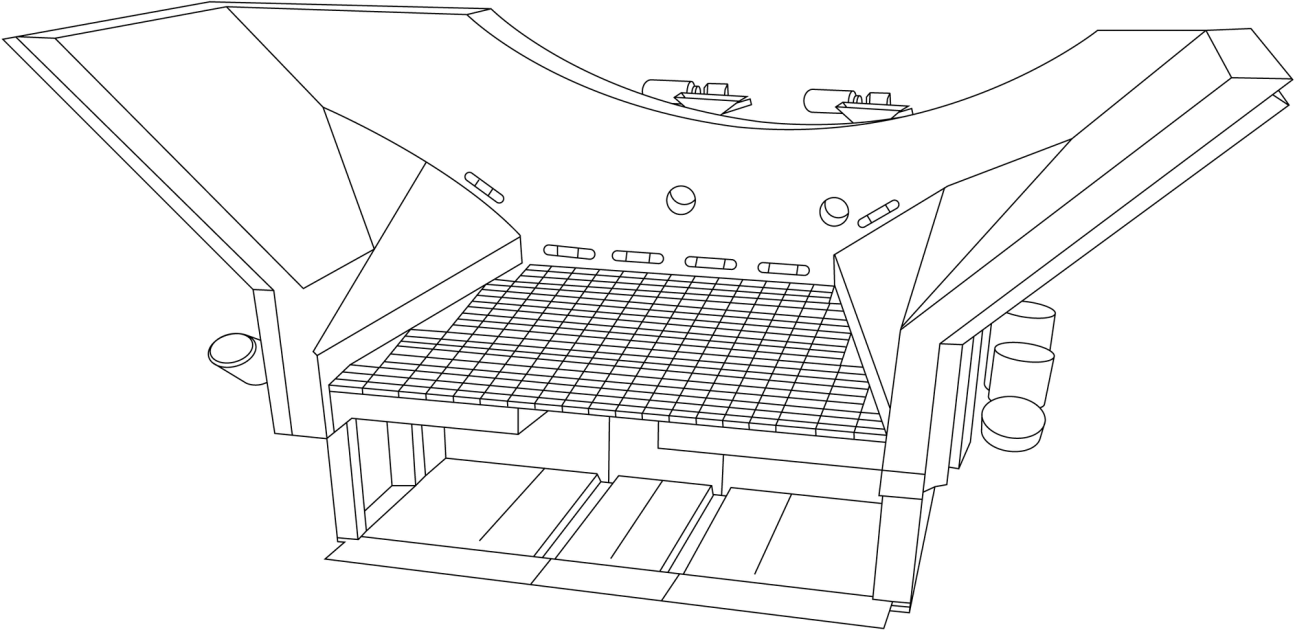

The HRB is the default clinker crusher type with our Cross-Bar® cooler. Because you can choose the number of rollers and the width of the HRB, it can be retrofitted to any existing cooler models and is easy to fit to coolers of all sizes.

In addition, we offer a mid-cooler option for those processes prone to high boulder build-up. By installing the clinker crusher near to the middle of the cooler we can ensure that the crushed clinker has time to cool properly before leaving the cooler.

Quick installation

The HRB arrives on site pre-assembled and pre-tested. Installation is simple and can be completed in less than 2 weeks to fit in with your annual shutdown.