Eliminate snowmen and improve heat recuperation with our ABC™ Cooler Inlet

The ABC Inlet is the world’s only cooler inlet proven to prevent snowman; it also enables reduced fuel consumption and improved clinker quality – a gain for the environment and your bottom line.

Increase uptime, improve quality, enhance efficiency

The use of alternative fuels and petcoke creates the perfect conditions for snowman formation. Once the dusty, sticky clinker has agglomerated you are in a race against the clock to eliminate the snowman before it affects productivity.

Goodbye snowmen. Hello uptime

Nobody wants snowmen or dead-zones in their cooler inlet. Both have to be monitored and removed – often manually – and mean costly production stops.

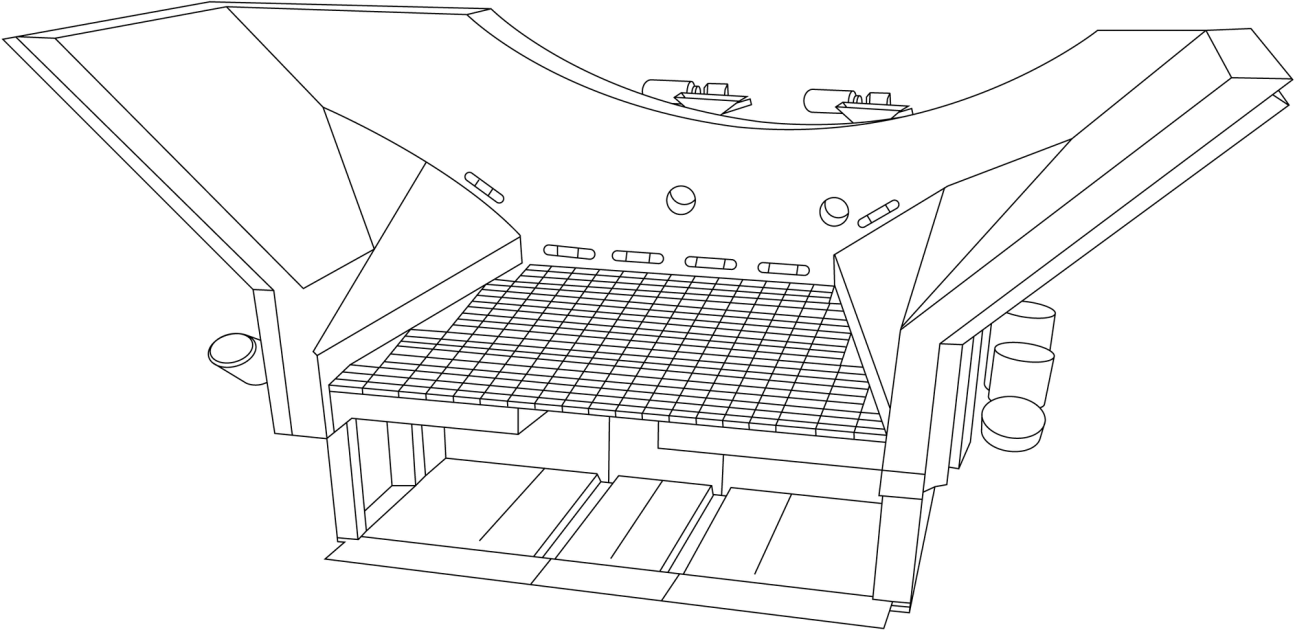

The ABC™ Cooler Inlet gives you the advantages of a stationary inlet section – good service life and good cooling-air distribution – with clinker conveyance and uniform clinker distribution.

Return on investment in less than 12 months

Investment of EUR 200,000-500,000

Short payback time: less than 12 months

Short erection time: 8-14 days

Short delivery time: 4-6 months

Available to all

The ABC Inlet is included as standard on all new coolers, but it is also available as an upgrade to existing coolers – whether or not they were supplied by FLSmidth. This relatively simple upgrade can be completed in 2 – 3 weeks and has an immediate impact on cooler performance – and on your finances. Savings on fuel consumption and maintenance, as well as gains in clinker quality,all add up to a generous and swift return on investment.

Take control of your operation and maintenance costs

01

Reduced fuel consumption and associated emissions

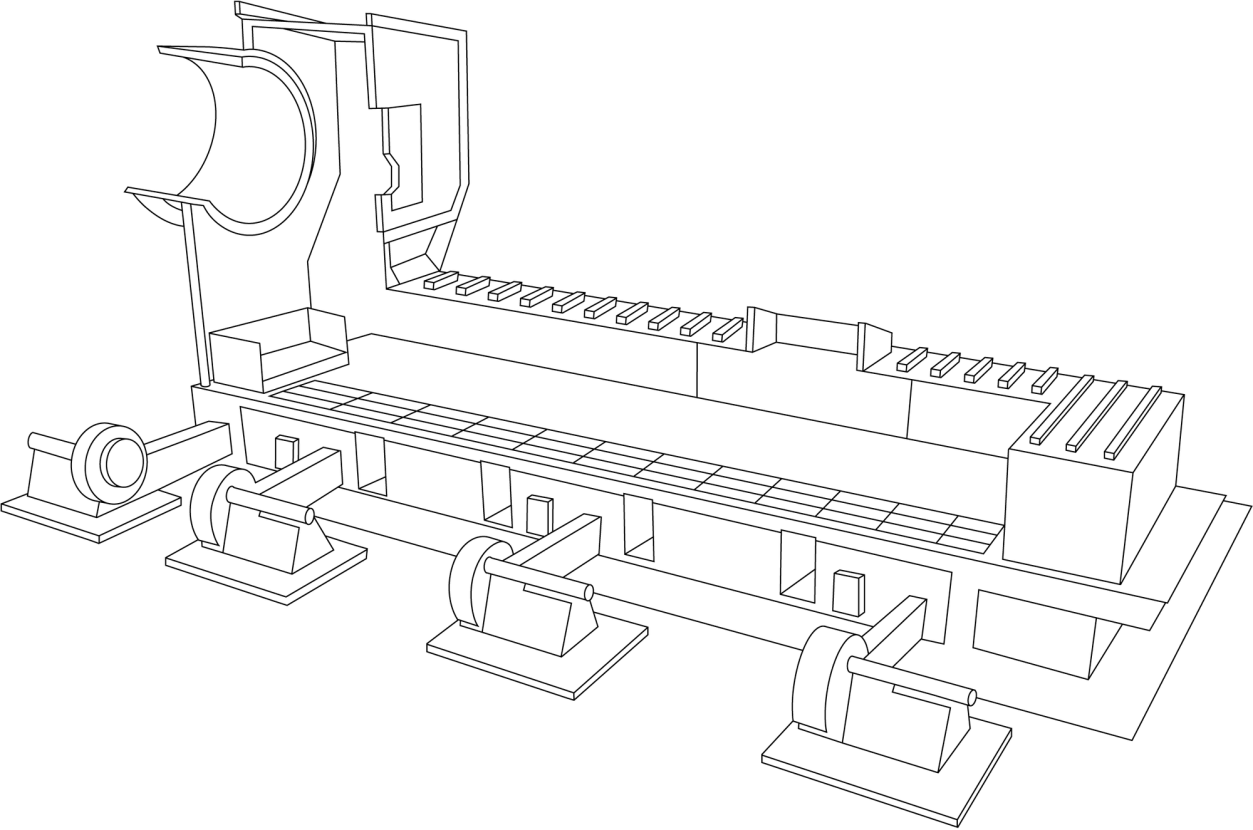

Thanks to its built-in MFR (Mechanical Flow Regulator) valves, you can control the cooling air to each individual grate plate and better regulate the flow of cooling air through the clinker bed across the inlet. This gives you faster and more even cooling – and better heat recuperation. As a result, you can decrease firing in the kiln or preheater – decreasing your alternative fuel costs.

02

Minimised maintenance requirements on cooler parts

The ABC™ Cooler Inlet gives you all the advantages of a stationary inlet section, including a long service life and good cooling-air distribution. But it also includes a unique patented in grate air blasting system, which means more uniform clinker distribution – and no snowmen. This adds up to better protection of mechanical parts, reducing your maintenance requirements.

03

No more snowmen

With no snowmen or dead-zones in your cooler inlet, your cement plant can run and run, without stopping production to clean the inlet. Eliminate snowmen with our cooler inlet – and reduce your production stops.

Superior clinker distribution and consistent cooling

Better control of your blasting areas

The blasting area is divided into 3-8 zones, depending on the size of the inlet. Within each zone, you can regulate blasting frequency and intensity to suit your production schedules. Pre-defined programmes – controlled from the Central Control Room – combine zones, frequency and intensity in a set pattern to give you even greater control.

Automatic flow regulation

The ABC™ Cooler Inlet is aerated with our well-proven MFR valve system, which maintains a consistent supply of cooling air across the whole inlet section, irrespective of the clinker bed depth and porosity. The valves maintain a constant flow of air through each grate plate and automatically compensate for the varying resistance of the clinker bed.

Space-saving air cooling system

The air blaster system releases compressed air directly through the grates and into the clinker bed using the same air distribution system as normal cooling air. This ensures complete area coverage for cooling and blast air – and means you don’t need space for two different distribution systems.

Grate slots for better flow

The fixed inlet consists of a steel support frame to support the air distribution grates. Both the smooth grate line and the built-in forward-facing air slots greatly enhance clinker flow during normal cooling operation.