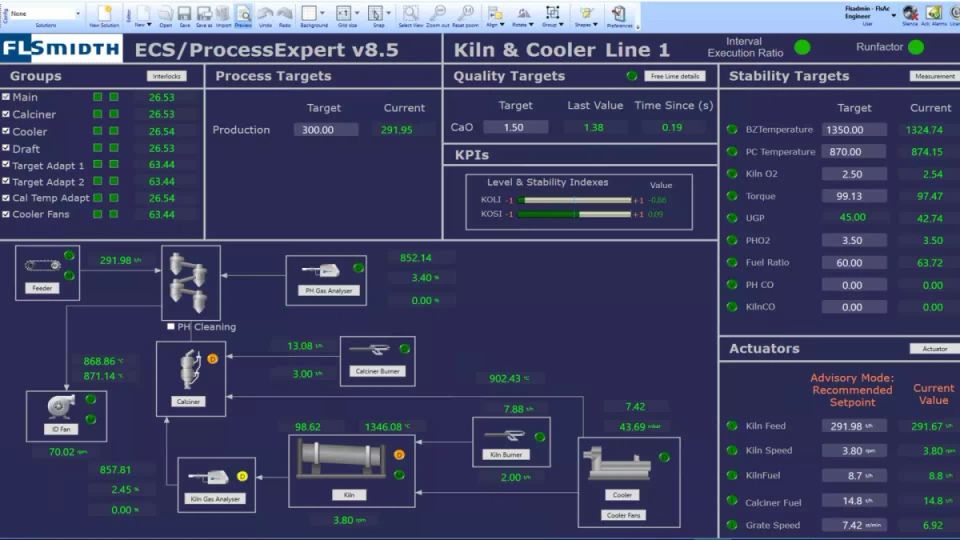

Increase production and cut costs with ECS/ProcessExpert® advanced process control software

An intelligent control solution for the cement industry

With decades of experience supporting the cement industry, we know how much of a drain high energy and maintenance costs can be on your business. We also understand that the competitive landscape means you are constantly looking for ways to increase production and get an edge over your competition. Our ECS/ProcessExpert software was specifically designed with these needs in mind.

Improve your bottom line

Cut energy costs

Increase production

Reduced downtime, equipment wear and maintenance costs

Our ECS/ProcessExpert solution is packed with features to lift the performance of your operations. With our software, you can be confident that your plant and equipment are working to their best capacity, no matter what the conditions. And you’ll have the support of our remote team of experts to make sure our system is working as you need it to.

The ECS/ProcessExpert platform includes several advanced and intelligent process control technologies. It combines well-known control techniques, such as model predictive control (MPC), with symbolic and non-symbolic AI technologies based on machine learning and deep learning algorithms. The end goal? A system that is best able to solve problems related to the control and optimisation of the cement process.

What’s new in ECS/ProcessExpert® V9.0?

We’ve significantly enhanced measuring and reporting capabilities with Control Loop Performance Monitoring V1, as well as improved dashboards, benchmarking, and analysis. The updates mark a step-change in our ability to measure and manager a plant’s carbon footprint with V9.0 providing both conventional metrics, as well as the ability to track savings in more tangible ways. As an example: producers can now compare the CO2 savings delivered by an individual mill using our process expert system to the equivalent number of trees planted, smart phones changes, or barrels of oil consumed. We’ll also shortly roll-out V9.1 as a seamless upgrade to V9.0. This update will activate the adaptive control technology made possible through our collaboration with Lin & Associates. Watch out for more information on this exciting new development soon! Keeping up with the green transition... The latest update ensures we remain at the forefront of the green transition in the cement industry. It’s a concrete demonstration of our commitment to invest and develop automation solutions that will support cement plants on their decarbonization journey: a journey that requires a flexible control strategy to manage and optimize the introduction of more and diverse alternative fuels, raw materials, additives and supplementary cementitious materials into the cement-making process. The V9.0 update is available as an upgrade to existing ECS/ProcessExpert software, as well as third-party systems.