Crushed coal dosing that delivers on accuracy, efficiency and safety

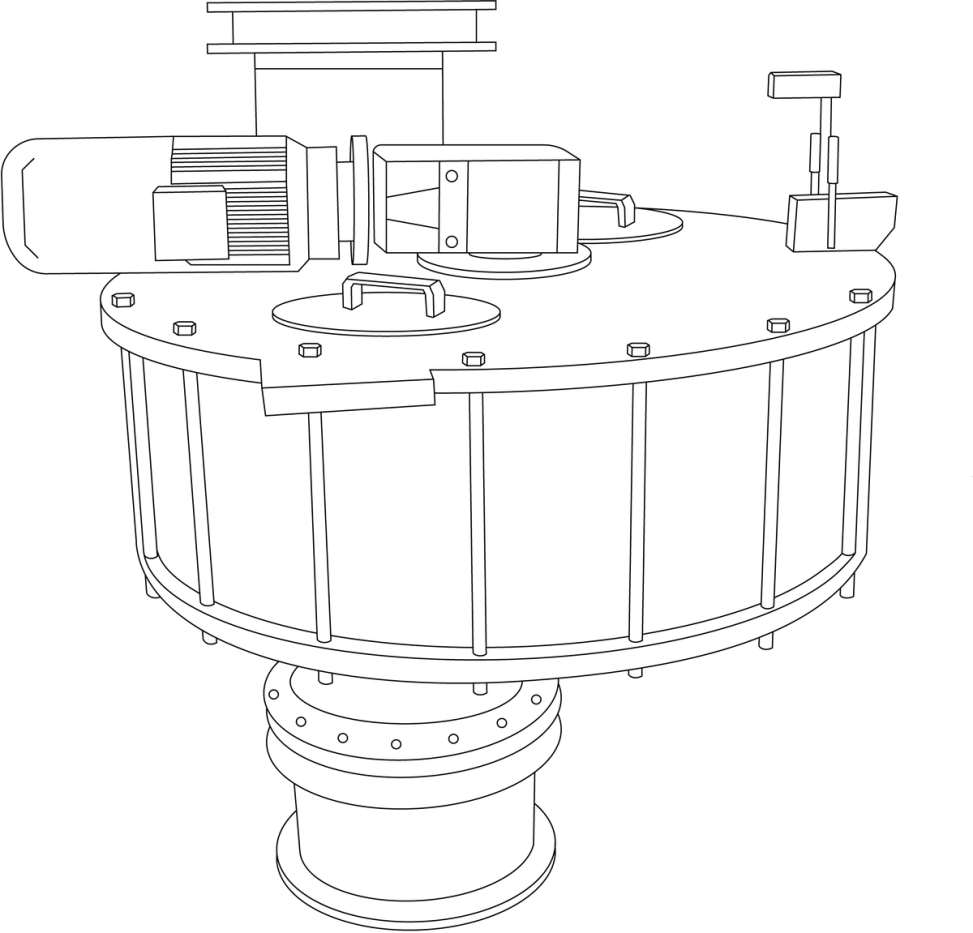

Coal feeding needs to be safe and it needs to be efficient. The PFISTER® TRW-K rotor weighfeeder ensures consistently accurate dosing of crushed coal to the mill in a safe, enclosed, pressure-proof system. Advanced weighing electronics provide constant precision, whatever your feed characteristics.

Gravimetric feeding of crushed coal for the ultimate accuracy

Coal feeds vary. Density. Size. Calorific value. Inconsistencies are to be expected. But that variability can make a big difference to the process if it isn’t accounted for. The PFISTER® TRW-K rotor weighfeeder for crushed coal uses advanced weighing electronics to ensure accurate dosing that reacts to changes in the feed. The equipment is robust and wear-resistant, making the complete system extremely reliable. Plus, it’s a totally enclosed, dust-tight, all-metal device in a pressure-proof design. Safe. Efficient. Reliable. Just what you need for your crushed coal feed.

Reliability by design. Equipment that understands your material

Patented rotor weighfeeder technology with added functionality

All PFISTER® rotor weighfeeders are based on the same weighing and dosing principle, as illustrated below.

Weighing and dosing principle

The system includes material extraction, weighing, dosing and feeding. First, material is extracted from the storage unit and transported in the rotor chambers (1) from the inlet (2) to the outlet (3). The rotor is mounted on bearings that form a weighing axis (A-A) eccentric to the rotor shaft, through the middle of the inlet. A third point is suspended at a load cell (6) where the content of the rotor wheel is weighed gravimetrically. The load is measured in kilograms and this data, together with the related position of the rotor wheel, is stored by the advanced weighing electronics. Weighing is carried out before discharge, so the weighing electronics have the opportunity to adjust the rotor wheel speed inverse to the load before the material leaves at the rotor outlet (3). This ensures highly accurate dosing for a more efficient process.

ProsCon®: Advanced Weighing Electronics

The secret to the high levels of accuracy achieved by PFISTER® rotor weighfeeders is the ProsCon® prospective control advanced weighing electronics. Being able to adjust the feed in response to the data from the gravimetric weighing process enables the PFISTER® TRW-K to ensure precise and consistent dosing, despite variation in the crushed coal feed. Adjustments to the feed rate can be made very quickly without loss of accuracy, so if ProsCon® detects a weight change – perhaps due to load displacement or the density of the coal – it doesn’t affect the actual quantity of coal being dosed. This results in an extremely accurate short- and long-term feed rate.