Feeding and dosing coarse and hot materials with precision

Gravimetric feeding for optimum precision, whatever your material

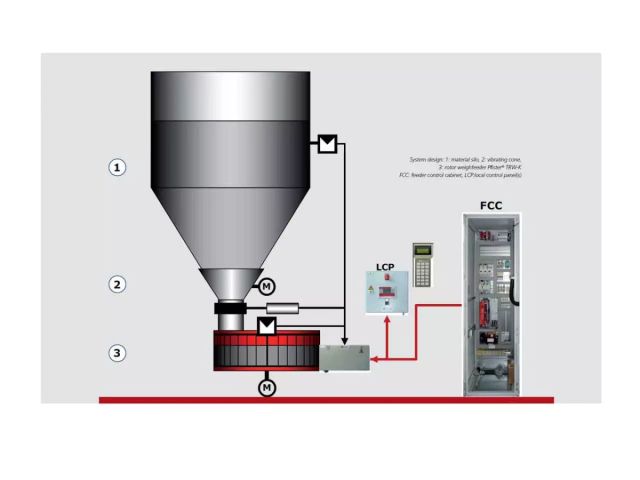

Your process needs accuracy and consistency to deliver optimum performance. But dosing coarse materials can make this difficult to achieve. Traditional volumetric weighing systems can’t cope with the variability of the feed, while the wear caused by handling abrasive and hot materials can give you endless maintenance headaches. The robust design of the PFISTER® TRW rotor weighfeeder is ideal for metering coarse and hot bulk materials such as clinker, pre-ground cement, limestone and gypsum with consistency and precision. Since the material only comes into contact with the steel rotor, wear is negligible. And as a complete system comprising material extraction, weighing and dosing, it’s easy to operate and very reliable. The gravimetric feeding technology enables high levels of accuracy and consistency, regardless of the variability in the materials. Our ProsCon® prospective control advanced weighing electronics anticipates changes in the feed and adjusts the rotor speed accordingly to ensure the output is always the same. Feed rates of up to 400 t/h are possible, as well as material temperatures up to 200˚C.

Outstanding reliability. Long service life. Accurate, every time

Precise, but flexible

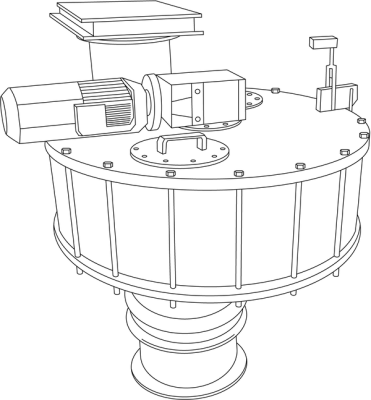

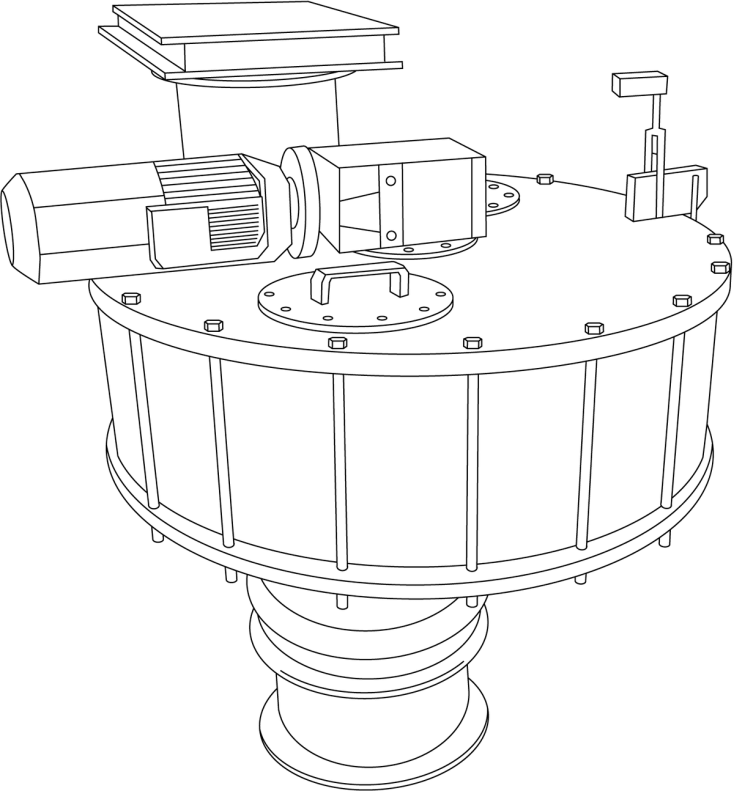

All our rotor weighfeeders are based on the same weighing and dosing principle. The picture below illustrates the process using a PFISTER® TRW.