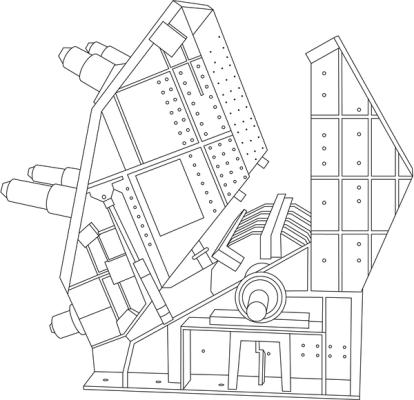

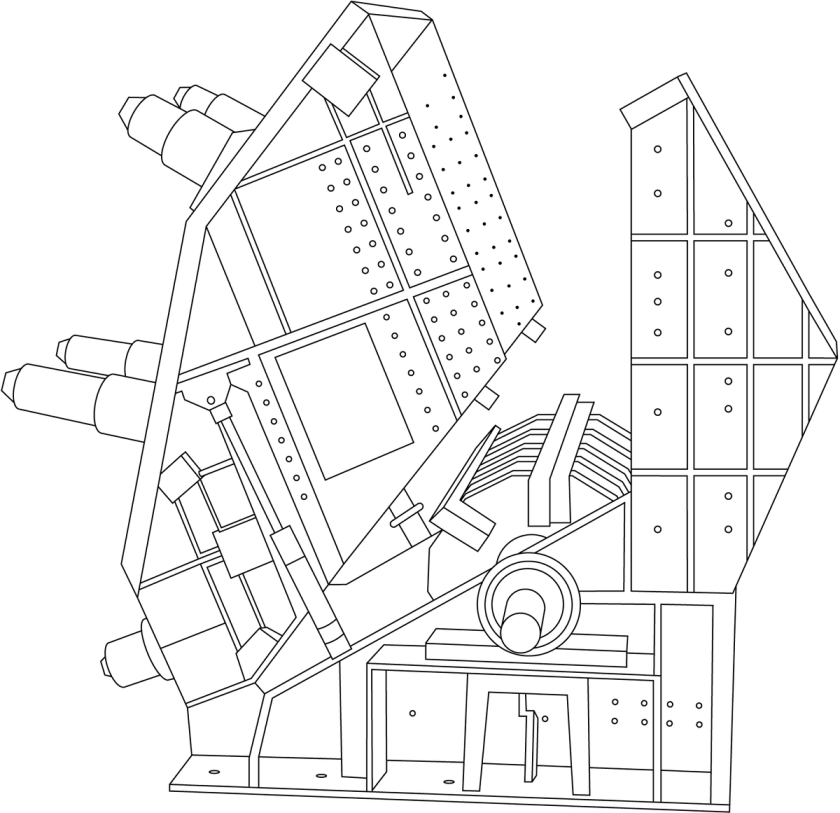

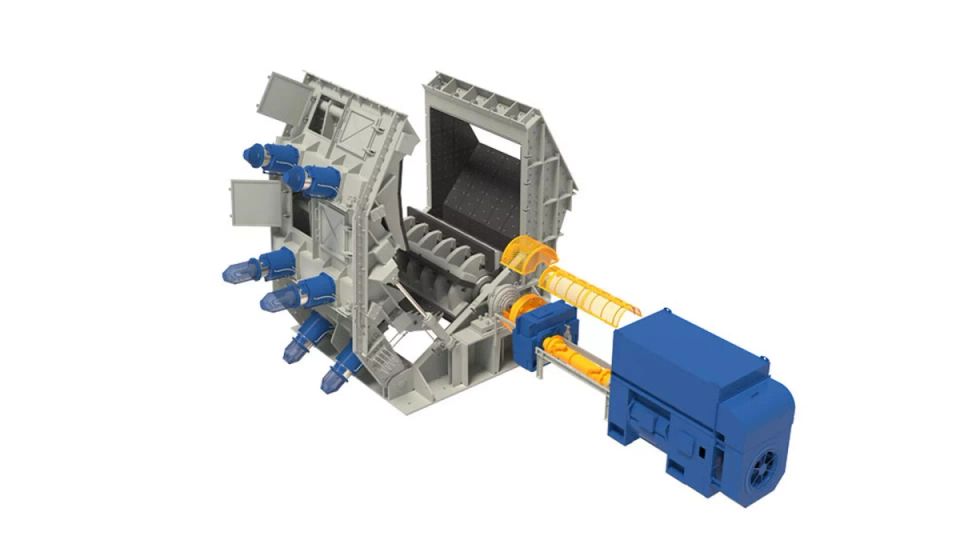

Reliable, low maintenance impact crushing with the Strike-Bar™ Crusher

Robust strike-bar impact crushing system achieves 1:40 size reduction

The FLSmidth Strike-Bar Crusher is a high-speed impact crusher designed specifically for the cement production process. Based on our proven technology, it is built to reduce the effect of wear in a harsh operating environment. With it, we aim to help your production operations achieve their true potential. The Strike-Bar Crusher is just one impact crushing solution within our complete family of crushing equipment. It is the perfect choice for crushing large rocks in a single rotor operation. It combines the latest crushing technologies with our extensive experience in crushing and cement production operations.

Maximise cement production with heavy-duty impact crushing

Low total cost of ownership

Long wear life

Easy maintenance

Greater production capacity

The FLSmidth Strike-Bar Impact Crusher is based on our proven technology, boasting features that reduce the effect of wear in a harsh operating environment.